limestone jaw crusher

A limestone jaw crusher is a device specifically designed for primary limestone crushing. It breaks large lumps of limestone into smaller particles suitable for subsequent processing. The price ranges from $50,000 to $150,000. Feed Inlet Size: 125-1200mm Maximum Feed Size: 1020mm Processing Capacity: 1-1000 t/h Discharge Adjustment Range: 10-350mm Motor Power: 5.5-280kW

Limestone Jaw Crusher Overview

Limestone is a sedimentary rock primarily composed of calcium carbonate. It has a moderate hardness and a relatively brittle texture, making it an important raw material for building materials such as cement, lime powder, and sand and gravel aggregates. Due to its widespread use in the construction, road construction, chemical, and metallurgical industries, limestone processing is in high demand. A limestone jaw crusher is a device specifically designed for primary limestone crushing, breaking large lumps into small particles suitable for subsequent processing. Typically, this equipment can handle feed sizes of 600mm or less, up to 1000mm, and has a wide processing capacity range, from 1 ton/hour to 1000 tons/hour, depending on the model and configuration. Its discharge size can generally be controlled between 10-350mm, meeting the needs of limestone processing lines of varying sizes.

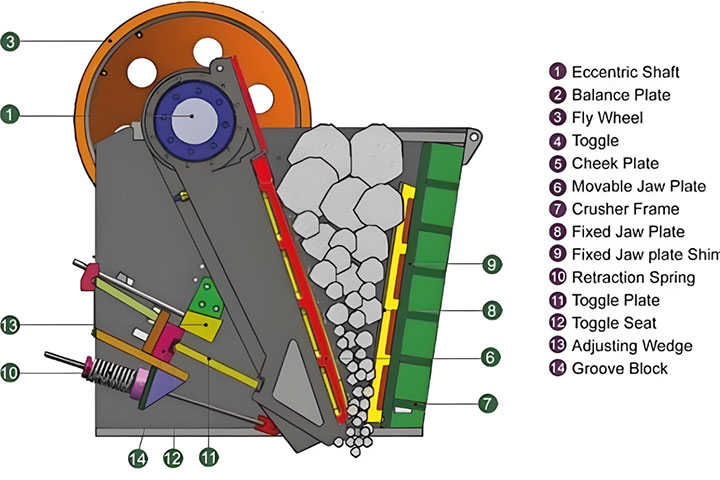

Limestone Jaw Crusher Structure

The limestone jaw crusher's structural design is relatively simple yet robust, primarily consisting of a frame, movable jaw, stationary jaw, eccentric shaft, toggle plate, flywheel, adjustment device, and lubrication system. The frame is the basic load-bearing structure of the equipment, ensuring overall stability. The movable and stationary jaws are each equipped with crushing liners (jaw plates) that directly participate in material crushing. The eccentric shaft is driven by a belt and motor to reciprocate the movable jaw. The toggle plate provides a safety feature, preventing serious damage when encountering unbreakable material. The flywheel stores energy and maintains stable operation. The adjustment device adjusts the discharge particle size. The lubrication system reduces friction during high-intensity operation, extending the equipment's lifespan. These components work together to make the limestone jaw crusher both durable and easy to maintain.

Working Principle of Limestone Jaw Crusher

The limestone jaw crusher operates in a typical extrusion crushing mode. When the motor drives the eccentric shaft via a pulley, the movable jaw reciprocates around a fixed point. As it approaches, it squeezes and impacts the limestone, crushing it. As it moves away, the crushed material is discharged from the crusher under its own weight, completing the crushing process. This process repeats continuously, gradually breaking large limestone lumps into smaller particles. Because the jaw crusher's reduction ratio is generally between 4 and 6, it is particularly suitable as a primary crusher for limestone, providing the appropriate feed size for subsequent impact crushers or sand making machines. Furthermore, its simple structure, high crushing efficiency, and stable operation make it a core piece of equipment in sandstone aggregate and cement production lines.

Limestone Jaw Crusher Technical Parameters

| Model | Feeding size(mm) | Max feeding size(mm) | Discharging Range size(mm) | Capacity (t/h) | Motor power(kw) | Weight (t) |

| PE-250*400 | 250*400 | 210 | 20-60 | 5-20 | 15 | 2.8 |

| PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.5 |

| PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 10.6 |

| PE-600*900 | 600*900 | 500 | 65-180 | 80-180 | 55-75 | 15.5 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 90-110 | 28 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 90-110 | 30 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 90-110 | 30.5 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 90-110 | 31 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 110-132 | 49 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 110-132 | 51 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160 | 100.9 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 22 | 4.9 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37 | 7.7 |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 75 | 11 |

Limestone Jaw Crusher Types

Limestone jaw crushers are primarily classified into several categories based on their movement and structure. They are categorized by their intended use into the PE series (for coarse crushing) and the PEX series (for medium and fine crushing). Furthermore, depending on their installation method, they can be divided into fixed jaw crushers (suitable for long-term production sites) and mobile jaw crushers (suitable for temporary quarries or road construction, as they can be moved with the site). The availability of these types of equipment allows users to flexibly select the appropriate equipment based on site conditions, production requirements, and investment budget.

Limestone Jaw Crusher Price

Limestone jaw crusher prices vary widely, depending primarily on model, processing capacity, manufacturer, brand, and configuration. A small jaw crusher (with a capacity of 1-30 tons/hour and a feed size ≤200mm) costs approximately $20,000-$30,000; a medium-sized jaw crusher (with a capacity of 30-300 tons/hour and a feed size ≤600mm) typically costs $30,000-$50,000; and a large jaw crusher (with a capacity of 300-1000 tons/hour and a feed size ≤1000mm) can cost between $50,000-$150,000. Mobile jaw crushers are more expensive, typically ranging from $100,000-$300,000. When considering price, users should comprehensively evaluate equipment lifespan, wear parts costs, and after-sales service, rather than focusing solely on the initial investment.

Limestone Crushing Production Line Flowchart

Limestone Jaw Crusher Solution

In practice, a limestone jaw crusher is typically not used standalone, but rather as the front-end equipment of a complete crushing and screening production line. A typical solution involves primary crushing with a jaw crusher, reducing large limestone lumps to 100-350mm. Secondary crushing with an impact crusher or cone crusher further reduces the particle size to below 40mm. Finally, a sand making machine and vibrating screen produce stone powder and aggregate that meet standards for construction sand or cement raw materials. For large limestone mines, a fixed production line is recommended to ensure long-term stable operation. For construction projects or temporary projects, a mobile jaw crusher is recommended for greater flexibility. This comprehensive solution also requires a conveyor, vibrating screen, and dust removal equipment to improve production efficiency.