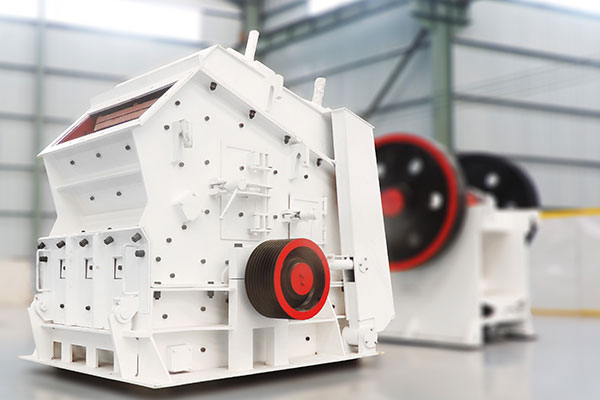

Granite jaw crusher

Granite jaw crushers are available in three common types: primary jaw crusher, secondary jaw crusher, and mobile jaw crusher. Prices generally range from $15,000 to $300,000. Feed size: 120-1500mm. Production capacity: 1-2200t/h. Power: 5.5-250kW. Discharge size: 10-300mm. Weight: 0.8-120t.

What is a Granite Jaw Crusher?

Granite jaw crusher is used for coarse crushing of hard ores or rocks, such as granite, and is part of a crushing line. The discharge size of a granite jaw crusher typically ranges from 20mm to 250mm, which can be adjusted by adjusting the wedge or spacer at the device's outlet. The output ranges from 5t/h to 800t/h. For example, the PE-250×400 model has an output of 5-20t/h. Equipment prices range from approximately US$20,000 to US$500,000, with prices varying depending on the model.

Granite Jaw Crusher Functions

The Granite jaw crusher has four main functions: Primary crushing, capable of crushing large granite blocks exceeding one meter in diameter into particles of 100–250mm, preparing for subsequent processing. For crushing high-hardness materials, high-manganese steel or special alloy jaw plates offer excellent impact and wear resistance, adapted to the high strength of granite. The discharge size is adjustable, with the discharge port width adjusted mechanically or hydraulically to control the finished particle size to meet diverse production needs. The large feed capacity and wide inlet allow direct access to material discharged from large machinery, reducing pre-processing steps and improving process automation and efficiency.

Granite Jaw Crusher Equipment Types

Granite Jaw Crusher for Primary Crushing: Provides primary crushing of granite, crushing large lumps ≤ 1200mm into 150-300mm. With a crushing capacity of 50-1000t/h, it features a large feed opening, high compressive strength, and a simple, durable structure, making it suitable for rough processing of high-hardness granite.

Granite Jaw Crusher for Secondary Crushing: Provides secondary crushing of granite after primary crushing, producing a 50-150mm output. With a crushing capacity of 30-800t/h, it features a deep crushing chamber, high crushing ratio, and uniform finished product shape, making it suitable for subsequent sand making or shaping processes.

Mobile Granite Jaw Crusher: Provides flexible processing of dispersed granite, integrating primary and secondary crushing functions. With a crushing capacity of 20-500t/h, it is mobile and removable, requiring no infrastructure, saving on raw material transportation costs and making it suitable for temporary outdoor crushing operations.

Granite Jaw Crusher Specifications

| Model |

Feeder Opening Size(mm) |

Max. Feeding Size (mm) |

Outlet adjusting Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

| PE400x600 | 400x600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-130 | 45 | 2150x1900x1950 |

| PE600x900 | 600x900 | 500 | 60-125 | 90-180 | 55 | 2500x2010x2350 |

| PE750x1060 | 750x1060 | 630 | 60-150 | 110-380 | 110 | 2630x2310x3110 |

| PE900x1200 | 900x1200 | 750 | 95-165 | 220-450 | 132 | 3720x2850x3250 |

| PE1000x1200 | 1000x1200 | 850 | 200-300 | 280-560 | 160 | 3820x2850x3250 |

| PE1200x1500 | 1200x1500 | 1020 | 150-300 | 400-800 | 220 | 4590×3342×3553 |

| PE1500x1800 | 1500x1800 | 1200 | 210-360 | 520-1100 | 280 | 5100x4700x4300 |

| PEX150x750 | 150x750 | 120 | 10-40 | 5-16 | 15 | 1310x1118x1145 |

| PEX250x750 | 250x750 | 210 | 15-50 | 15-30 | 22 | 1440x1751x1515 |

| PEX250x1000 | 250x1000 | 210 | 15-60 | 15-52 | 30 | 1730x1950x1400 |

| PEX250x1200 | 250x1200 | 210 | 15-60 | 20-60 | 37 | 1730x2150x1400 |

| PEX300x1300 | 300x1300 | 250 | 25-60 | 30-105 | 55 | 2000x2320x1730 |

Granite Jaw Crusher Price

The price of a Granite jaw crusher is influenced by a combination of factors, including the cost of raw materials such as steel, equipment production volume, model specifications, and technical content. Small or mobile crushers offer both flexible relocation and basic crushing capabilities, costing approximately $30,000 to $100,000, making them suitable for small or short-term projects. Medium-sized fixed production line equipment offers greater stability and automation, typically priced between $100,000 and $300,000, meeting the needs of medium-sized sand and gravel production. Large jaw crushers, featuring integrated intelligent control, high-pressure hydraulic adjustment, and wear-resistant design, offer extremely high production capacity and exceptional durability, costing between $500,000 and $1,000,000, and are designed for large-scale mines and intensive stone production facilities.

Key Features of a Granite Jaw Crusher

High Wear Resistance: The core components of the Granite jaw crusher, the movable and fixed jaws, are made of high-manganese steel or wear-resistant alloys to withstand the intense wear caused by the high hardness of granite (Mohs hardness 6-7), extending the replacement cycle of wear parts.

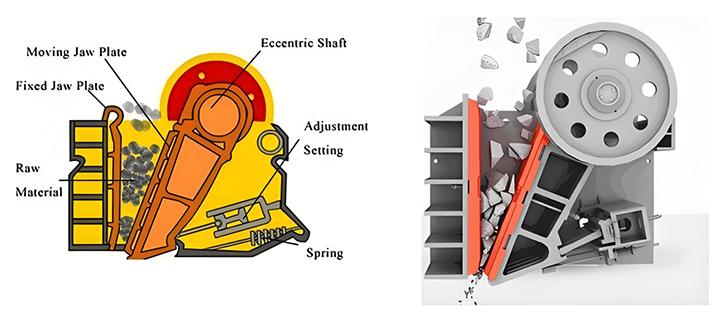

Powerful Crushing Capacity: The deep V-shaped crushing chamber design increases the feed opening and processing space. Combined with the high-speed eccentric shaft drive, it can rapidly crush and crush granite, with a processing capacity of tens to thousands of tons per hour.

Stable Operation: The machine body is constructed of heavy-duty welded steel, providing strong rigidity and excellent vibration resistance, capable of withstanding the tremendous impact of granite crushing. An overload protection device automatically shuts down the machine when encountering unbreakable debris, preventing damage.

Energy Efficiency: The optimized transmission system reduces power loss, reducing energy consumption by 10%-15% compared to traditional equipment. The crushed product is uniform in shape, reducing the burden on subsequent shaping processes.

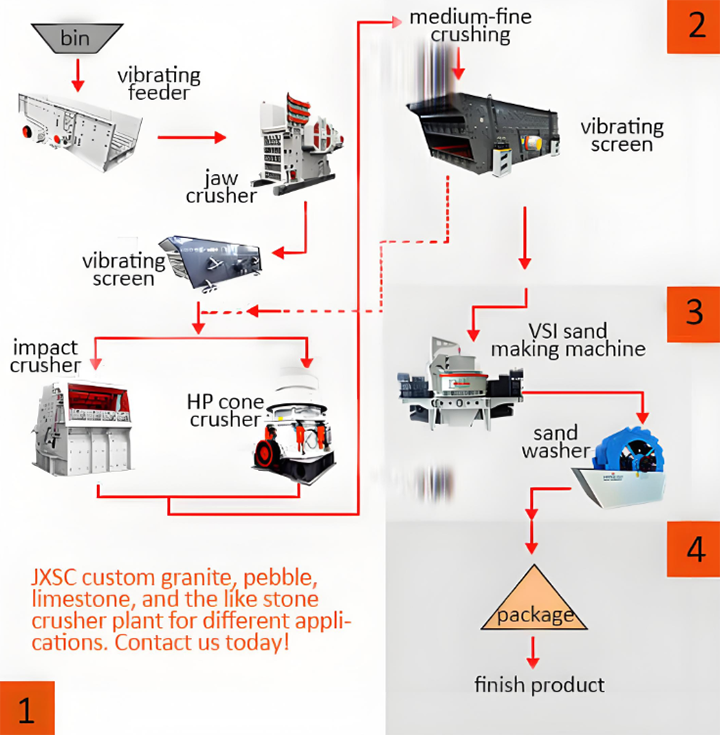

Flexible Adaptability: The Granite jaw crusher can be combined with a vibrating feeder, screening equipment, and other equipment to form a complete crushing line. The discharge port can be adjusted to meet the required granite particle size, flexibly controlling the material output. This makes it suitable for various applications, such as construction aggregates and road construction.

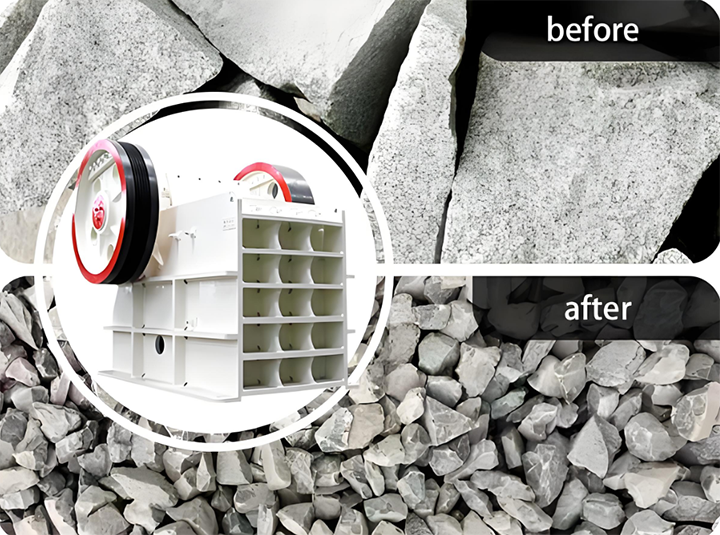

How to Crush Granite?

First, a Granite jaw crusher uses the squeezing action of its movable and fixed jaws to coarsely crush large granite blocks (≤1.2 meters in diameter) to 30-50 cm, suitable for feeding subsequent equipment. A cone crusher then utilizes the principle of laminated crushing to reduce the coarse crushed material to 5-15 cm, minimizing overcrushing. If fine powder or sand and gravel are required, an impact crusher or ball mill is used for fine crushing. This process requires a vibrating screen to classify the material, returning unqualified material for re-crushing, and dust removal equipment to treat dust.

Granite jaw crusher process flow

Granite jaw crusher for sale

When purchasing a Granite jaw crusher, choose a model with the appropriate processing capacity based on your production needs. Pay attention to the material quality of wear parts, such as the jaw plate, to ensure durability, and consider the machine's adjustable features to facilitate control of the output particle size.As a mining equipment manufacturer, our jaw crushers are renowned for their sturdy construction and robust craftsmanship. Our company uses high-quality steel and precision machining to ensure the reliability and long service life of our equipment's core components. This makes it a reliable choice for processing hard materials like granite. We welcome your visit for a trial run.

Applications of Granite of Different Sizes

Granite crushed by the Granite jaw crusher and other crushing equipment is used in a wide variety of applications.

Large-sized slabs, such as 1200x2400mm and 1600x3200mm, are primarily used for large-scale floor paving, wall hangings, and large countertops in buildings. They minimize seams and create a grand, integrated visual effect.

Medium-sized slabs, such as 600x600mm and 800x800mm, are the most commonly used sizes and are widely used for floor paving and wall decoration in various locations, including shopping malls, office buildings, and residences. They offer convenient installation and a high cost-effectiveness.

Small and special-shaped sizes, such as 100x100mm and 300x600mm, are often used in kitchen backsplashes, bathroom decorations, skirting boards, stair treads, and other detailed areas, providing functional division and decorative elements.

Slab stones, such as 100x100x1000mm, are primarily used in outdoor projects such as plazas, road curbs, and path paving. They are durable and sturdy.