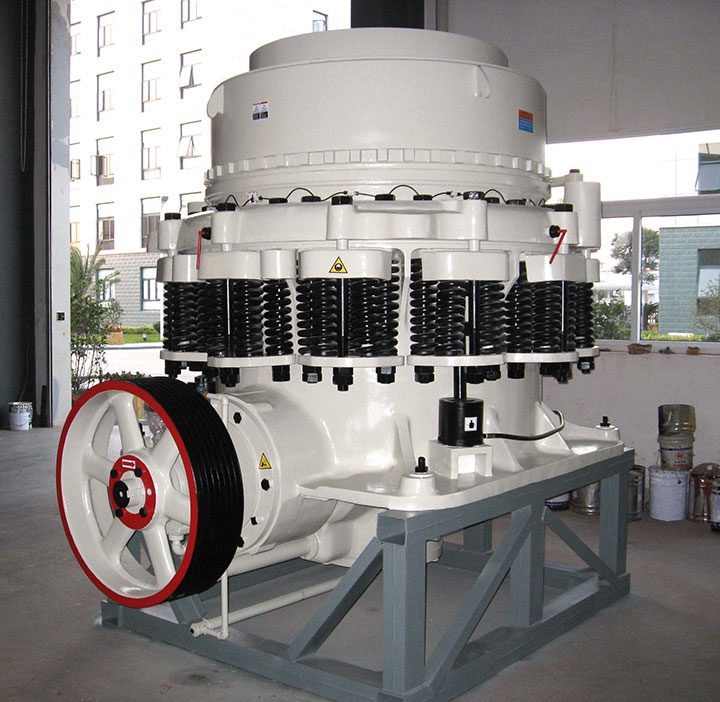

Glauconite cone crusher

The glauconite cone crusher can perform medium-to-fine crushing of glauconite, with adjustable output size. It is used for post-mining crushing of glauconite. The price ranges from US$100,000 to US$200,000. Feed size: ≤300mm Production capacity: 12 - 700 tons/h Applications: Glauconite medium-to-fine crushing and other applications

What is a glauconite cone crusher?

Glauconite is a mineral that primarily forms in marine sedimentary environments, commonly found in shallow and deep-sea sandstone, limestone, or mudstone. It is typically dark green, bluish-green, or blackish-green in color and has a relatively low hardness (Mohs hardness 2-3). Glauconite's value lies in its natural and environmentally friendly nature, and its ability to replace some artificial chemical materials and reduce costs.

Glauconite cone crusher are often used to crush glauconite in production. Different equipment sizes have varying processing capacities: a Φ600 cone crusher has a processing capacity of 12-40 tons/hour, while a Φ2200 cone crusher has a processing capacity of 80-700 tons/hour. The crushing ratio is generally between 3 and 10, with short-head crushing chambers offering a higher crushing ratio. The motor power of a Φ1200 standard cone crusher is 110kW, while that of a Φ2100 standard cone crusher is 280kW. The main shaft speed of the Φ1200 standard cone crusher is 230 rpm, while that of the Φ1650 short-head cone crusher is 300 rpm. Crushing chamber types include standard, medium, and short-head. The standard cone crusher is suitable for coarse crushing, while the short-head cone crusher is suitable for fine crushing. Equipment prices generally range from US$100,000 to US$200,000.

What are the benefits of a glauconite cone crusher?

The Glauconite cone crusher is ideal for crushing glauconite due to its low hardness and brittleness. Its benefits include:

Adapting to glauconite's physical properties and reducing over-crushing: Due to its low hardness, glauconite requires crushing to 10-50mm for subsequent grinding or processing. Using equipment with excessively high impact forces (such as an impact crusher) can easily produce a large amount of fines, which doesn't meet process requirements. The Glauconite cone crusher utilizes a laminated crushing principle (dynamic and fixed cone compression) to achieve gentle and uniform crushing force, control particle size, and improve the yield of acceptable material.

Higher crushing efficiency for lump/nodule-like materials: Glauconite is naturally found in lumps or nodules (each weighing 1-5kg), requiring initial medium/fine crushing. The Glauconite cone crusher's feed opening (30-100mm) is suitable for bulk materials, and its gradual crushing chamber design ensures optimal material retention time and prevents clogging. Compared to jaw crushers, which are suitable for coarse crushing and uneven material discharge, the crushing efficiency is 30%-50% higher, making it ideal for intermediate crushing of glauconite.

Reduced equipment wear and maintenance costs: Glauconite's low hardness causes minimal wear on the equipment. However, the jaw plates of traditional jaw crushers operate in rigid impact contact, which can lead to localized wear due to compression over time. The Glauconite cone crusher's movable and fixed cones are made of wear-resistant alloys. The interplay of materials during laminated crushing cushions direct impact between the equipment and the material, reducing wear by 20%-30%. This extends maintenance cycles and reduces downtime costs, making it suitable for continuous, large-scale production.

Meeting the precise particle size requirements of subsequent processes: Glauconite applications (such as potash fertilizer processing and water purifier preparation) have strict particle size requirements. For example, potash fertilizer production requires crushing to 20-30mm before grinding. Uneven particle size reduces grinding efficiency. The Glauconite cone crusher precisely controls the output particle size (with an accuracy of ±2mm) by adjusting the gap between the moving and fixed cones, ensuring stable subsequent grinding and screening processes.

Glauconite cone crusher technical parameters (reference)

| Type | Model | Cavity Type | Diameter of cone (mm) |

Adjusting Range of Discharge Opening (mm) |

Recommend feeding size when the minimum output size (mm) |

Max feed size (mm) |

Capacity (t/h) |

Main Motor Power (kw) |

Weight (kg) |

Overall Dimension (L×W×H) (mm) |

| 2’FT | PSGB- 0607 | Standard fine | 600 | 6-38 | 70 | 60 | 16-50 | 30 | 4500 | 2195×1158×1651 |

| PSGB- 0609 | Standard medium | 10-38 | 95 | 80 | 18-65 | |||||

| PSGB- 0611 | Standard coarse | 13-38 | 110 | 90 | 22-70 | |||||

| PSGD- 0603 | Short head fine | 3-13 | 35 | 30 | 9-35 | |||||

| PSGD- 0605 | Short head coarse | 5-16 | 50 | 40 | 22-70 | |||||

| 3’FT | PSGB- 0910 | Standard fine | 900 | 9-22 | 102 | 85 | 45-91 | 75 | 9980 | 2656×1636×2241 |

| PSGB- 0917 | Standard coarse | 13-38 | 175 | 150 | 59-163 | |||||

| PSGB- 0918 | Standard super coarse | 25-38 | 178 | 150 | 118-163 | |||||

| PSGD-0904 | Short head fine | 3-13 | 41 | 35 | 27-90 | 10530 | ||||

| PSGD-0906 | Short head medium | 3-16 | 76 | 65 | 27-100 | |||||

| PSGD-0907 | Short head coarse | 6-19 | 102 | 85 | 59-129 | |||||

| 4.25’FT | PSGB- 1313 | Standard fine | 1295 | 13-31 | 137 | 115 | 109-181 | 160 | 22460 | 2983×1866×3156 |

| PSGB- 1321 | Standard medium | 16-38 | 210 | 178 | 132-253 | |||||

| PSGB- 1324 | Standard coarse | 19-51 | 241 | 205 | 172-349 | |||||

| PSGB- 1325 | Standard super coarse | 25-51 | 259 | 220 | 236-358 | |||||

| PSGD-1306 | Short head fine | 3-16 | 64 | 54 | 36-163 | 22590 | ||||

| PSGD-1308 | Short head medium | 6-16 | 89 | 76 | 82-163 | |||||

| PSGD-1310 | Short head coarse | 8-25 | 105 | 89 | 109-227 | |||||

| PSGD-1313 | Short head super coarse | 16-25 | 133 | 113 | 118-236 | |||||

| 5.5’FT | PSGB- 1620 | Standard fine | 1676 | 16-38 | 209 | 178 | 181-327 | 250 | 43270 | 3941×2954×3771 |

| PSGB- 1624 | Standard medium | 22-51 | 241 | 205 | 258-417 | |||||

| PSGB- 1626 | Standard coarse | 25-64 | 269 | 228 | 299-635 | |||||

| PSGB- 1636 | Standard super coarse | 38-64 | 368 | 313 | 431-630 | |||||

| PSGD-1607 | Short head fine | 5-13 | 70 | 60 | 90-209 | 43870 | ||||

| PSGD-1608 | Short head medium | 6-19 | 89 | 76 | 136-281 | |||||

| PSGD-1613 | short head coarse | 10-25 | 133 | 113 | 190-336 | |||||

| PSGD-1614 | Short head super coarse | 13-25 | 133 | 113 | 253-336 | |||||

| 7’FT | PSGB- 2127 | Standard fine | 2134 | 19-38 | 278 | 236 | 544-1034 | 400 | 86730 | 4613×3302×4638 |

| PSGB- 2133 | Standard medium | 25-51 | 334 | 284 | 862-1424 | |||||

| PSGB- 2136 | Standard coarse | 31-64 | 369 | 314 | 1125-1814 | |||||

| PSGB- 2146 | Standard super coarse | 38-64 | 460 | 391 | 1252-1941 | |||||

| PSGD-2110 | Short head fine | 5-16 | 105 | 89 | 218-463 | 89500 | ||||

| PSGD-2113 | Short head medium | 10-19 | 133 | 113 | 404-580 | |||||

| PSGD-2117 | Short head coarse | 13-25 | 178 | 151 | 517-680 | |||||

| PSGD-2120 | Short head super coarse | 16-25 | 203 | 172 | 580-744 |

What types of Glauconite cone crushers are there?

Glauconite cone crushers are primarily categorized by their structure as spring-loaded and hydraulic.

Spring-loaded Glauconite cone crushers rely on a spring mechanism for overload protection. When hard impurities such as quartz are mixed into the glauconite, the spring compresses, driving the moving cone backward to prevent the equipment from jamming. This device is suitable for small- to medium-sized glauconite crushing lines with a daily output of less than 500 tons. It is particularly well-suited for applications where raw materials contain small amounts of impurities, require stable equipment, and have limited budgets. It offers the advantages of a simple structure, easy maintenance, and low replacement costs for wear-resistant parts such as the movable and fixed cones. However, it has a low degree of automation and requires manual adjustment of the spring tension to control the crushing size.

The hydraulic glauconite cone crusher replaces traditional springs with a hydraulic system. Its core advantages are automatic overload protection and precise particle size adjustment. A hydraulic valve allows for real-time adjustment of the gap between the movable and fixed cones without manual intervention. This device is suitable for large-scale glauconite production lines with a daily output of more than 500 tons. It is particularly suitable for applications such as potash fertilizer plants that require continuous and stable production and have strict requirements for output particle size accuracy (e.g., 20-30mm with a ±2mm tolerance). Its high degree of automation and crushing efficiency are 20%-30% higher than spring-type crushers, significantly reducing downtime and making it more suitable for long-term, large-scale glauconite processing.

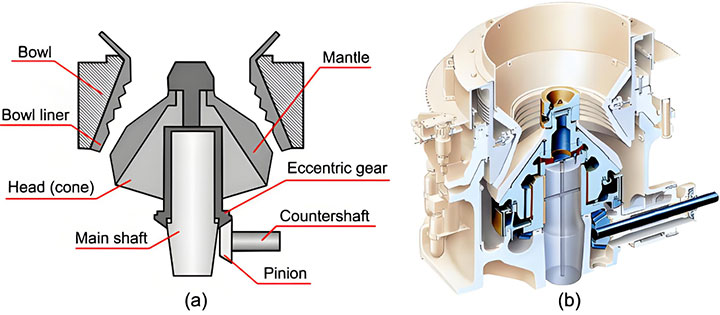

Glauconite Cone Crusher Structure

A Glauconite cone crusher consists of a fixed cone, a rotating cone, a main shaft, an eccentric gear, a countershaft, and a pinion. During operation, the motor drives the main shaft through the countershaft and pinion, causing the eccentric gear to drive the main shaft in eccentric motion. The rotating cone and the fixed cone lining form a crushing chamber, crushing glauconite.

What are the applications of the Glauconite Cone Crusher?

In the mining industry, the Glauconite Cone Crusher can be used to crush various ores, such as iron ore and copper ore. In the construction industry, it is often used to produce building aggregates and can crush hard rocks such as limestone and granite. In the metallurgical industry, it is used to crush metal raw materials. In the chemical industry, it can be used to crush chemical raw materials such as barite and calcite. It can also be used in road construction, water conservancy projects, and other fields to crush related stone materials.

Glauconite Cone Crusher Price

A small spring-loaded Glauconite Cone Crusher costs between $30,000 and $50,000. Some medium-sized cone crushers with moderate processing capacity cost around $60,000 to $150,000. Large, high-performance hydraulic glauconite cone crushers, on the other hand, can cost $200,000, with some costing over $300,000. The choice depends on the glauconite production capacity and machine configuration.