Large grain crusher for feed mills

Saturday January-31 2026 15:38:26

Large grain crusher for feed mills is used in feed production to pulverize various types of grains with a particle size not exceeding 100mm into coarse or finer pellets, providing raw materials for subsequent mixing and pelleting processes. They utilize a high-speed rotating rotor that drives hammers to pulverize grains into fine particles between 0.8-8mm. The processing capacity can reach 5-100 tons per hour, suitable for handling large quantities of grain.

Large grain crusher for feed mills can be used to pulverize different types of grains, from low to high hardness. Depending on the type of grain being crushed, hammer mills, roller mills, and toothed crushers are available.

What types of Large grain crushers for feed mills are there?

There are many types of large grain crushers for feed mills, mainly three types: hammer mill, roller mill, and toothed claw mill. They differ in their crushing methods and output.

Hammer mill Large grain crusher for feed mills: These crush grains by impacting them with high-speed rotating hammers. The fineness of the crushing is adjustable from 10-80 mesh, and the hourly processing capacity is 5-50 tons. They can be used to crush most feed grains such as corn, wheat, and sorghum, as well as auxiliary materials containing small amounts of straw.

Roller mill Large grain crusher for feed mills: These crush grains by squeezing and grinding them with two opposing rotating rollers. The crushing process is gentle and does not generate excessive dust or temperature rise. They are generally used to crush hard grains such as corn and barley, with an hourly output of 10-80 tons and an output particle size adjustable from 20-100 mesh. The crushed material has uniform particles and retains the nutritional components of the grain, making it suitable for large-scale feed production lines with high requirements for crushing quality.

Toothed claw type large grain crusher for feed mills: It uses the shearing and impact action of high-speed rotating toothed claws and fixed toothed claws to crush grains. It has strong crushing force and can crush medium and soft grains and shells such as rice and peanut shells. The hourly processing capacity is 3-30 tons, and the crushing fineness is 15-60 mesh. The crushed material is generally in powder or fine particles, which is suitable for customers who need fine powder feed.

What are the advantages of a large grain crusher for feed mills?

The large grain crusher for feed mills features high-manganese steel hammers and a thickened, wear-resistant casing, making it impact-resistant and wear-resistant. It can crush grains of varying hardness, with a large crushing capacity of up to 100 tons. Equipped with a 30-110KW high-power motor, the output fineness is adjustable from 1-8mm, resulting in highly uniform crushed material without clumping or large particles. Customization of the feed inlet and discharge methods, as well as the feed inlet size, is also available. For grains with high dust content, a dust removal device is provided to purify the dust generated during the crushing process.

How do Large grain crusher for feed mills work?

When large grain crushers for feed mills are working, grains fall into the crushing chamber through the feed inlet. The hammers, driven by a motor, strike the grains, and the fixed toothed plates further crush the grains, breaking large pieces into smaller particles. The crushed material is then sieved through a screen. Material that meets the specifications is discharged from the outlet, while unqualified coarse material is returned to the crushing zone for secondary crushing until it meets the required specifications.

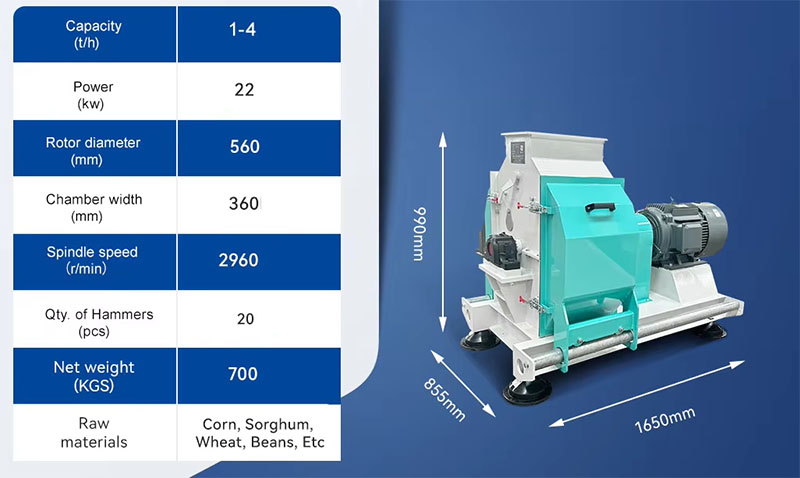

Large grain crusher for feed mills parameters

| Model | SFSP56X36 | SFSP56X40 | SFSP56X60 |

| Capacity (t/h) | 1~4 | 1.5-6 | 2-7 |

| Power (kW) | 22 | 37 | 45 |

| Sieve Aperture (mm) | φ1-3 | φ1-3 | φ1-3 |

| Rotor Diameter (mm) | 560 | 560 | 560 |

| Cavity Width (mm) | 360 | 400 | 600 |

| Spindle Speed (r/min) | 2960 | 2965 | 2965 |

| Hammers (pcs) | 20 units | 24 PCS | 36 units |

| Net Weight (kg) | 700 | 800 | 998 |

| Dimensions (mm) | 1467*855*990 | 1650*855*990 | 1878*855*1010 |

| Raw Materials | Corn, sorghum, wheat, beans, etc. | ||

| Note: Raw material is corn, &le. 13%-14% moisture | |||

What are the applications of Large grain crusher for feed mills?

Large grain crusher for feed mills is mainly used in the pre-treatment stage of grain raw materials in feed processing plants. They can crush large grains to the particle size required for subsequent pelleting and mixing. They can be used to crush various types of grains such as corn, wheat, barley, sorghum, oats, buckwheat, soybean meal, cottonseed meal, and rapeseed meal, producing a particle size of 1-5mm without damaging the nutritional components of the raw materials.

How to Select a Large Grain Crusher for Feed Mills?

When selecting a large grain crusher for feed mills, you need to consider the hardness and moisture content of the grain. Generally, for medium-hardness grains such as corn and wheat, a hammer mill is recommended; for sorghum, barley, or materials with a moisture content exceeding 15%, a roller mill is preferable. Next, consider the particle size. For piglet feed requiring 1-2mm fine powder, choose a model with an adjustable screen; for fattening feed requiring 3-5mm coarse particles, adjust the roller gap. Also consider the production capacity. Large plants should choose models with an hourly output of 5-20 tons. Finally, consider the application scenario. For workshops with limited space, a vertical model with a floor area of ≤3㎡ is recommended.

Large grain crusher for feed mills Manufacturer

MACHRISE Large grain crusher for feed mills manufacture various types of grain crushers, including hammer crushers, roller crushers, and claw crushers, with processing capacities ranging from 5 to 100 tons per hour. These crushers can break large grain particles into smaller particles or powders with a particle size of 1-8mm. Depending on the application, both stationary and mobile models are available. For applications with high dust levels requiring dust collection and purification, models with dust removal devices are also available. Customized products can be made based on the grain properties, output, and application requirements. Factory direct sales, prices ranging from $350 to $9500.

Chinese Herb Grinder Machine

Chinese Herb Grinder Machine Seeds Coarse Crusher

Seeds Coarse Crusher