Dolomite cone crusher

The Dolomite cone crusher is used for secondary and tertiary crushing of dolomite, with prices ranging from $8,000 to $250,000. Feed size: 24-370mm Discharge size: 6-51mm Production capacity: 60-3035t/h Power range: 160-1000kW Applicable materials: River pebbles, granite, dolomite, etc.

What is a Dolomite cone crusher?

Dolomite is a carbonate mineral primarily composed of calcium magnesium carbonate. It is often rhombohedral, white or gray, and has a Mohs hardness of 3.5-4. The Dolomite cone crusher typically has a feed size of 24-370mm and a discharge size of 6-51mm, with a production capacity of approximately 60-2500t/h. Types include single-cylinder hydraulic cone crushers and multi-cylinder hydraulic cone crushers. The price range is roughly between $1,000 and $250,000.

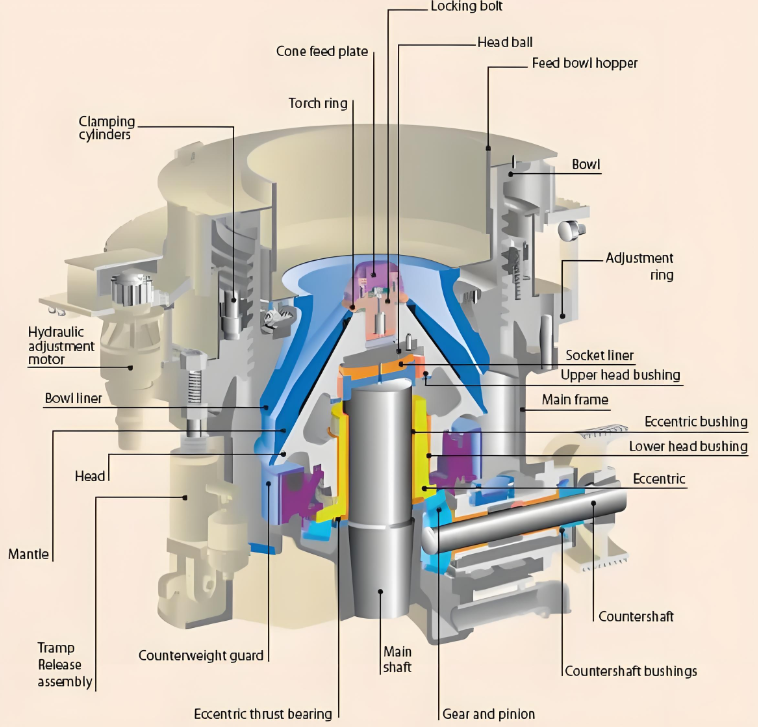

How does a Dolomite cone crusher work?

Dolomite cone crusher uses an electric motor to rotate a horizontal shaft. An eccentric sleeve on the shaft forces the moving cone to oscillate. Dolomite material enters through the top feed port and undergoes multiple compression, impact, and bending actions within the crushing chamber formed by the moving cone and the stationary cone liner, crushing it to the desired particle size. Smaller dolomite particles that meet the requirements are discharged from the bottom by gravity, achieving continuous crushing. Its core principle is to crush medium-hardness dolomite into fine shapes using the lamination principle.

What are the functions of a Dolomite cone crusher?

The Dolomite cone crusher has a strong dolomite processing capacity and is more efficient than traditional equipment, making it suitable for large-scale dolomite processing. It can control the crushed dolomite particle size, resulting in uniform and well-graded finished particles with minimal needle-like or flake-like particles, meeting the quality requirements of industries such as construction and building materials. Its core components are made of highly wear-resistant materials adapted to the hardness of dolomite, reducing component wear, extending equipment life, and lowering maintenance costs. Some models feature an intelligent control system that adjusts crushing parameters in real time based on dolomite feed rate and hardness, ensuring stable production and facilitating remote monitoring and operation. The optimized seal design also reduces dust emission, ensuring compliance with dolomite production standards.

What are the two types of Dolomite cone crushers?

Dolomite cone crushers are categorized by their operating principle and structure: spring cone crushers and hydraulic cone crushers. Hydraulic cone crushers are further divided into single-cylinder and multi-cylinder models.

Spring Dolomite Cone Crusher

A giant spring assembly encased within the crusher body acts as a protective device for over-iron flow and adjusts the discharge opening. When processing dolomite, it typically handles material moisture levels below 5%, feed sizes typically less than 300mm, and production rates typically range from 50 to 500 tons/hour. Its crushing ratio is moderate, approximately 5-10. This equipment typically costs between $100,000 and $300,000 USD.

In the process, it is often placed after the jaw crusher as a secondary or tertiary crusher. Due to its simple structure, stable operation, and flexible feeding requirements, it can be easily integrated with upstream and downstream feeders, vibrating screens, sand making machines, and other equipment to form a two- or three-stage crushing and screening process.

Single-Cylinder Hydraulic Dolomite Cone Crusher

The crusher has a single hydraulic cylinder on top. Its adaptability to dolomite moisture is slightly better than that of a spring cone crusher, but it is also recommended to keep the moisture content below 5% to prevent clogging. Its maximum feed size is approximately 350mm. It offers high production capacities, typically ranging from 100 to 1,000 tons/hour, and a high reduction ratio, reaching 10-15 or even higher. Its price is mid-range to high-end, typically ranging from $300,000 to $800,000 USD, depending on the model and configuration.

This crusher primarily performs secondary or tertiary crushing. Due to its high efficiency and advanced automation, it is the core crushing equipment for large and medium-sized production lines. Its hydraulic system facilitates automatic iron feeding and discharge adjustment, making it easily integrated with central automated control systems. It can be combined with large jaw crushers, feeders, and screening equipment to form a highly efficient, intelligent crushing production line.

Multi-cylinder Hydraulic Dolomite Cone Crusher

Multiple hydraulic cylinders are distributed around the crusher body. This high-end equipment is designed for high-intensity, high-efficiency fine crushing. It has the most stringent material moisture requirements, typically requiring dolomite moisture below 3% to ensure efficient lamination crushing and precise discharge control. The maximum feed size is similar to that of a single-cylinder crusher. Its core strengths lie in its extremely high production capacity and excellent reduction ratio, easily reaching 200-2000 tons/hour with a maximum reduction ratio of 15-20, directly producing large quantities of high-quality cubic particles. Prices typically range from US$500,000 to US$1.5 million or more.

The process is almost exclusively for tertiary crushing (sometimes also for secondary crushing), located at the end of the production line to produce high-quality end products. Designed for high-end production lines, it requires integration with precision feeding equipment (such as vibrating feeders) and fine screening equipment. It demands the highest levels of process stability and automated control, making it an ideal choice for large-scale modern aggregate mines and sand and gravel aggregate production lines.

Dolomite cone crusher technical specifications

| Specification | Model | Diameter of large end of crushing cone (mm) | Max.feeding size(mm) | Width of discharge opening (mm) | Processing capacity (t/h) | Motor power (kw) | Total weight (t) | Dimensions (L×W×H) (mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 8P 30 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | |||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 8P 55 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | |||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 8P 110 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | |||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 8P 160 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910×2894×3809 | |||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | 3910×2894×3809 | |||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 8P 280-260 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622×3302×4470 | |||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 | 4622×3302×4470 |

What materials can the Dolomite cone crusher crush?

The Dolomite cone crusher is suitable for crushing a variety of medium-hard and hard-brittle non-metallic and metallic ores. These include non-metallic ores such as quartz, limestone, granite, basalt, and diabase, as well as metallic ores such as iron ore, copper ore, lead, and zinc ore. It is also suitable for secondary and tertiary crushing of materials such as concrete aggregates, waste concrete blocks, crushed stone, and refractory materials.

Dolomite Production Flowchart

Dolomite Cone Crusher Application Scenarios

Dolomite cone crushers can crush dolomite into standard building aggregates for use in concrete, asphalt, and wall materials production, meeting the needs of buildings, roads, and bridges. In mining, they can also provide medium and fine crushing of raw ore, providing suitable particle sizes for flotation and magnetic separation. In the chemical industry, they can crush dolomite to specific particle sizes for the production of light calcium carbonate and magnesium oxide, which are used in the plastics, rubber, and coatings industries. Furthermore, in the further processing of building materials, they can provide coarse or medium crushing before milling and brickmaking, laying the foundation for subsequent fine processing.