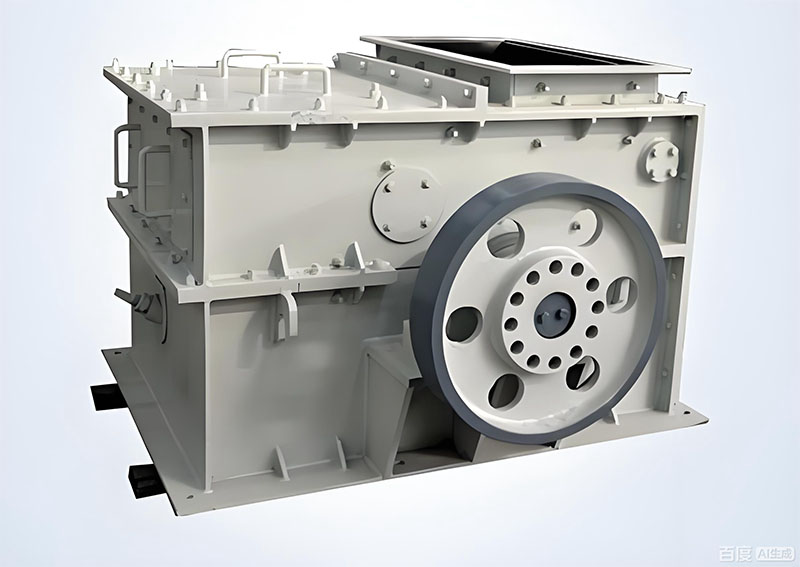

Ring Granulator Coal Crusher

Saturday January-31 2026 15:39:04

The Ring Granulator Coal Crusher crushes and granulates large coal lumps into the particle size required for power plants. Through the coordinated operation of a ring-shaped crushing chamber and a granulation mechanism, it processes lumpy and powdery coal into uniform particles with a discharge particle size of 1-10mm. This solves problems such as uneven raw coal particle size, inconvenient transportation, and incomplete combustion. It can also be used to process complex materials such as wet coal and sticky coal, improving coal utilization and reducing pollution. The crushing capacity is 5-50 tons per hour.

What are the advantages of the Ring Granulator Coal Crusher?

The Ring Granulator Coal Crusher features an integrated design of ring crushing and granulation, capable of crushing lumpy coal while directly pressing the crushed coal powder into uniform particles, reducing the hassle of secondary processing. The crushing chamber's wear-resistant lining is made of high-strength alloy material, offering impact resistance and wear resistance. The particle formation rate is over 90%, resulting in high-strength, non-pulverized finished particles that are easy to store and transport. It can process a wide variety of coal types, including coals of varying hardness and prone to caking, as well as wet coal with a moisture content of 8%-15%. Customization of output particle size, dimensions, and motor power is also available to meet specific site requirements.

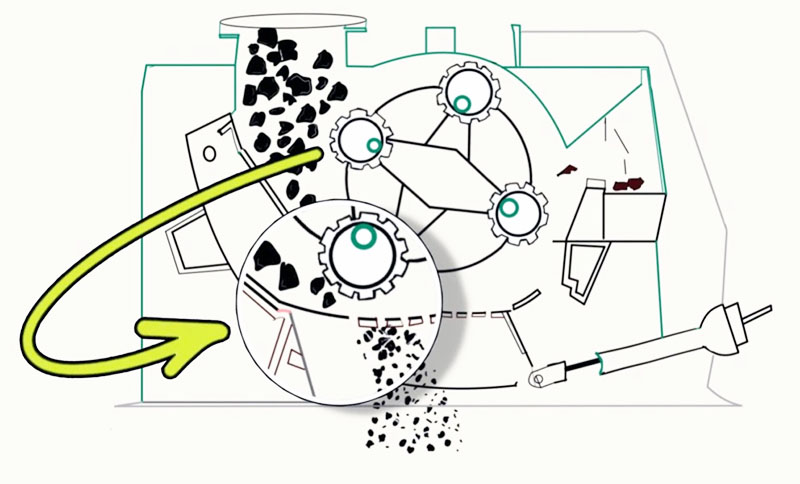

How does the Ring Granulator Coal Crusher work?

When the Ring Granulator Coal Crusher is in operation, coal enters the annular working chamber through the feed inlet. The motor-driven annular crushing assembly, in conjunction with the fixed liner, generates compression, grinding, and shearing forces, gradually crushing large pieces of coal into fine particles. The internal design includes an anti-stick coating and a gap adjustment device to prevent clogging by wet coal and to meet different particle size requirements. The crushed coal particles are then graded by a bottom screen; qualified particles are discharged directly, while unqualified particles are returned to the chamber for secondary crushing.

Ring Granulator Coal Crusher Parameters

| Parameters | Grading roller crusher | Jaw crusher | Ring hammer crusher | Mobile crushing station |

| Feed size | ≤1800mm | ≤1500mm | ≤400mm | ≤1000mm |

| Discharge size | 50-300mm adjustable | 100-300mm | ≤25mm | 50-200mm adjustable |

| Processing capacity | 800-2500t/h | 500-2000t/h | 600-1200t/h | 200-800t/h |

| Motor power | 220-450KW | 160-400KW | 280-500KW | 200-350KW |

| Equipment weight | 45-85 tons | 30-75 tons | 25-50 tons | 60-100 tons |

| Applicable coal type | Various coals | High hardness coal | Medium hardness and below coal | Various coals |

| Power consumption per ton of coal crushed | ≤0.5kWh/t | ≤0.6kWh/t | ≤0.7kWh/t | ≤0.8kWh/t |

What are the applications of the Ring Granulator Coal Crusher?

The Ring Granulator Coal Crusher is used to crush and granulate raw coal into uniform ring-shaped particles, improving coal utilization and facilitating transportation and storage. It is commonly used in coal mining, coal preparation plants, coal chemical production, thermal power generation, and boiler fuel preparation. It can crush anthracite, bituminous coal, lignite, lean coal, and coal with high moisture content or high hardness. In actual production, it is often used in conjunction with vibrating feeders and belt conveyors to achieve continuous feeding and material transfer, and with vibrating screens to complete post-crushing grading and screening. It can also be connected to coal granulators, dryers, and pulverizers to form a complete "crushing-grading-deep processing" production line, meeting the needs of coal crushing, purification, and resource utilization in different scenarios.

Ring Granulator Coal Crusher Customer Cases

| Customer Type | Application Scenarios | Crushed Material | Feed Size | Discharge Particle Size | Crushing Capacity |

| A Chinese open-pit coal mine | Integrated operation of coarse crushing and granulation of raw coal at the mine entrance, reducing costs and increasing efficiency for subsequent washing and transportation | Freshly mined raw coal, containing a small amount of gangue, compressive strength ≥80MPa | Maximum 300-600mm, average 200-350mm | Particle size after granulation: 10-30mm, particle roundness ≥85%, over-crushing rate ≥5% | Hourly output: 280-320 tons, 16 hours of operation per day, daily output: approximately 4500 tons |

| A coal preparation plant in Europe and America for coal-to-oil production | Deep processing of refined coal, including crushing and granulation, for pretreatment of raw materials in coal-to-oil processes to improve reaction efficiency | Washed coarse coal, ash content ≤12%, moisture 15%-20% | 50-200mm, free of large, hard impurities | Particle size after granulation 5-15mm, particle size uniformity ≥90%, meeting the feed requirements of the gasifier | 180-220 tons per hour, 300 operating days per year, annual output approximately 1.3 million tons |

| A Russian thermal power plant | Coal crushing and granulation for power generation solves problems such as incomplete combustion and slagging of raw coal, reducing energy consumption | Power coal, calorific value 5500 kcal/kg, containing a small amount of sulfur | 80-350mm, some agglomerated material requires pretreatment to break up | After granulation, particle size is 8-25mm, particle compressive strength ≥3MPa, combustion efficiency increased by 12% | Production capacity 250-280 tons per hour, meeting the full-load operation requirements of two 300MW units |

| A German metallurgical service company | Recycling and utilization of metallurgical by-products: crushing and granulating coke dust and coal powder into industrial fuel | Mixture of coke fines and coal powder from steel plants, with uneven particle size and containing less than 10% metallic impurities | 0.1-50mm, first screened to remove large impurities | After granulation, the particle size is 6-10mm, density ≥1.2g/cm³, which can replace part of the metallurgical coke | Output of 30-40 tons per hour, realizing the resource utilization of industrial solid waste, processing approximately 250,000 tons of waste annually |

Coal Coarse Crusher

Coal Coarse Crusher