Marble cone crusher

Marble cone crushers are used for secondary and fine crushing of large marble blocks, producing high-quality aggregates of varying particle sizes for use in the construction, building materials, and decorative industries. Prices typically range from $30,000 to $500,000. Feed opening size: ≤560mm Production capacity: 36-2,181 tons/hour Discharge opening adjustment range: 3-64mm Spindle speed: ≤485 rpm Motor power: 90-750kW

What is marble cone crusher?

Marble cone crusher can crush both medium and fine marble. Their capacity typically ranges from 50 to 500 tons/hour, depending on the model and configuration. Their output size can be adjusted between 5 and 50 mm, while their feed size generally does not exceed 200 mm. The equipment is primarily constructed of high-manganese steel or alloy steel with wear-resistant components. Motor power typically ranges from 75 to 315 kW. Prices typically range from US$30,000 to US$500,000.

Marble is a natural stone with a relatively low hardness (approximately 3-4 on the Mohs scale), high compressive strength, excellent thermal conductivity, and ease of cutting, carving, and polishing. It is used for applications such as wall coverings, sculptures, threshold stones, aggregates, and fillers.

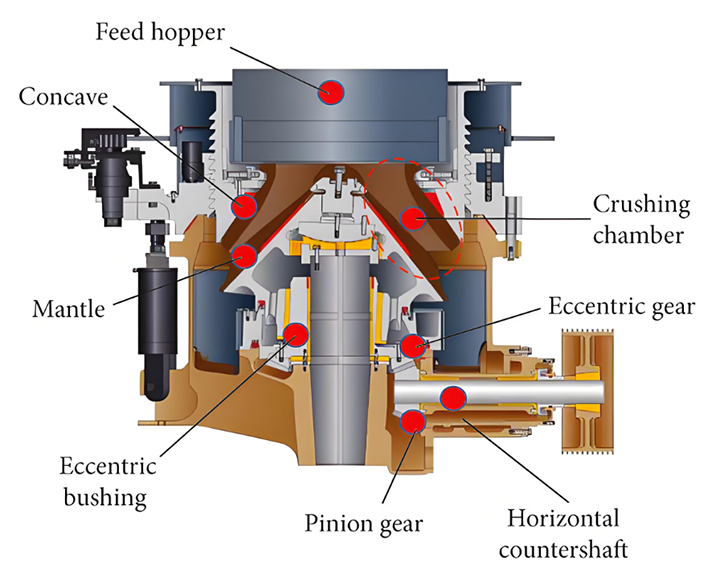

How does a marble cone crusher work?

Marble cone crusher operates based on the "laminated crushing" principle. Its core structure consists of a fixed outer cone (fixed cone) and a movable inner cone (moving cone). The motor drives the drive shaft, which rotates the eccentric sleeve, causing the movable cone to oscillate eccentrically around the main shaft, forming a periodically opening and closing crushing chamber with the fixed cone. Marble material enters the crushing chamber from the feed inlet. As the movable cone oscillates, it is initially compressed by the large upper clearance area. As the material moves downward, the clearance in the crushing chamber gradually decreases. The material is continuously compressed and bent by the fixed and movable cones, becoming finer, and finally, finished marble that meets the required particle size is discharged from the bottom discharge port.

Marble Cone Crusher Specifications

|

Model |

Max. Feeding Size (mm) |

Adjustable Range of Outlet (mm) |

Capacity (t/h) |

Motor Power (kW) |

Weight (t) |

Overall Dimension (mm) |

| PYB600 | 65 | 12-25 | 20-40 | 30 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 30 | 5.5 | 2234×1370×1675 |

| PYB900 | 115 | 15-50 | 50-90 | 55 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 55 | 11.2 | 2692×1640×2350 |

| PYD900 | 45 | 3-13 | 15-50 | 55 | 11.3 | 2692×1640×2350 |

| PYB1200 | 145 | 20-50 | 110-168 | 110 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 110 | 25 | 2790×1878×2844 |

| PYD1200 | 50 | 3-15 | 18-105 | 110 | 25.6 | 2790×1878×2844 |

| PYB1750 | 215 | 25-60 | 280-480 | 160 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 115-320 | 160 | 50.3 | 3910×2894×3809 |

| PYD1750 | 85 | 5-15 | 75-230 | 160 | 50.4 | 3910×2894×3809 |

| PYB2200 | 300 | 30-60 | 490-800 | 260/280 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 200-580 | 260/280 | 80 | 4622×3302×4470 |

| PYD2200 | 100 | 5-15 | 120-340 | 260/280 | 81.4 | 4622×3302×4470 |

What are the types of marble cone crushers?

Marble cone crushers are available in the following four types, each with its own unique characteristics. Choose the appropriate type based on your production capacity and the desired marble particle size.

The spring marble cone crusher is the most traditional type. It uses a large spring assembly as a metal overload protection device. When uncrushable material (such as iron) enters the crushing chamber, the spring is compressed, causing the movable cone to descend, widening the discharge port and expelling the foreign material. The spring then returns to its original position. The crushing particle size range is 25-102mm, and the production capacity can reach 36-748 tons/hour. It features a relatively simple structure, low cost, high reliability, and easy maintenance.

The multi-cylinder hydraulic marble cone crusher is a mainstream device in modern secondary and fine crushing. It utilizes multiple hydraulic cylinders surrounding the main unit to control crushing force, provide iron overload protection, and perform cavity clearing. Its hydraulic system automatically adjusts the discharge opening and crushing force, automatically discharging and resetting the crusher in the event of foreign matter without downtime. It also allows for rapid clearing of blockages, ensuring continuous production and convenient particle size control. It handles particle sizes from 16-95mm and has a production capacity of 60-650 tons/hour.

The single-cylinder hydraulic marble cone crusher features a highly integrated design, with a single hydraulic cylinder performing support, adjustment, and protection functions. It handles particle sizes from 19-51mm and has a production capacity of 72-1100 tons/hour. Its simple structure, minimal failure points, and high cost-effectiveness combine to deliver excellent lamination crushing results, resulting in fine-grained, low-flake content. It is widely used in secondary and fine crushing, particularly where quality is paramount.

The fully hydraulic marble cone crusher is an advanced model, utilizing dual upper and lower hydraulic cylinders for support, eliminating the traditional mechanical structure. Hydraulic coordination precisely controls the cone's motion, allowing for a wide adjustment range of the discharge opening, accommodating secondary, fine, and ultra-fine crushing operations. It offers exceptional flexibility and adaptability. The crushing range typically ranges from 8-51mm, with a production capacity of 60-650 tons/hour.

Selection Recommendations:

Secondary Crushing (secondary crushing after coarse crushing): A multi-cylinder hydraulic cone crusher or a single-cylinder hydraulic cone crusher. These crushers offer stable production capacity and excellent particle shape.

Fine Crushing/Sand Making (producing aggregates of 0-5mm, 5-10mm, or manufactured sand): A multi-cylinder hydraulic cone crusher, a single-cylinder hydraulic cone crusher, or a fully hydraulic cone crusher are all suitable.

Marble Cone Crusher Price Range

Spring-loaded marble cone crushers are easy to maintain and are suitable for small to medium-sized production lines or applications where the final particle shape is less critical. Prices typically range from $30,000 to $100,000+. Hydraulic marble cone crushers are a modern mainstream device with a high degree of automation, convenient discharge port adjustment and chamber cleaning, improved iron protection, and superior finished product particle shape. Prices typically range from $70,000 to $300,000+. Multi-cylinder hydraulic marble cone crushers are high-performance devices suitable for both secondary and tertiary crushing, offering high crushing force, high efficiency, and excellent product particle shape. Prices typically range from $150,000 to $500,000+.

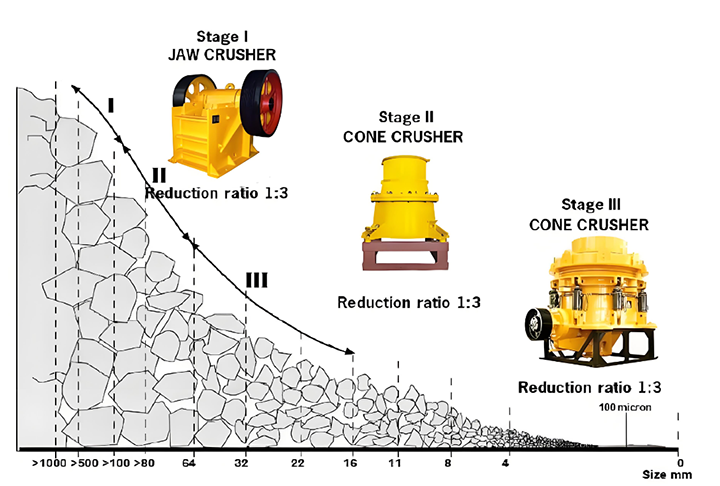

Marble Cone Crusher Process

A jaw crusher is typically used for primary crushing, breaking large marble lumps into smaller pieces. A marble cone crusher is then used for secondary and tertiary crushing, producing finished aggregate with a beautiful particle shape and uniform size.

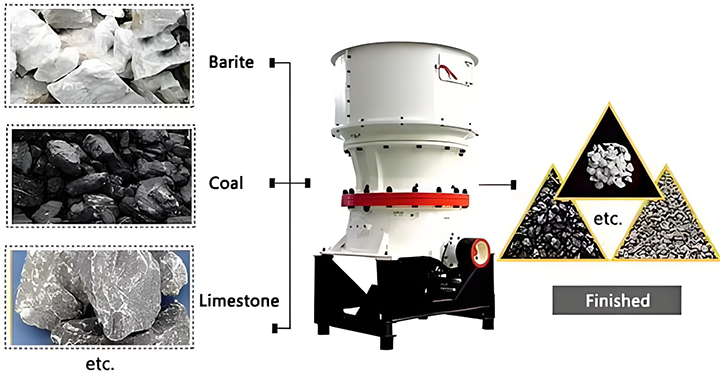

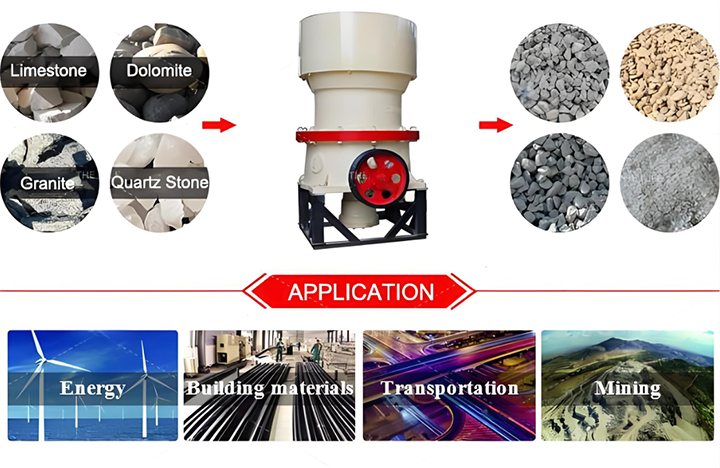

What is a marble cone crusher used for?

The marble cone crusher is a crushing machine designed for medium-hard materials such as marble. Its core applications are concentrated in marble processing and related fields, including:

Post-mining coarse and secondary crushing of marble: Mined marble blocks are crushed into small pieces that meet subsequent processing requirements, providing the raw material for slab cutting and handicraft production.

Architectural decoration: Marble waste and scraps are crushed to produce marble aggregate of varying particle sizes for use in the production of indoor and outdoor floor and wall decorative stone, or as an admixture in high-end decorative concrete.

Building materials and infrastructure: Crushed marble particles are used in road base paving and permeable brick production. Their wear resistance and aesthetic properties enhance the appearance and durability of infrastructure projects.

Waste recycling: Dust and debris generated during marble processing are processed and reused in artificial marble production after crushing and grading, thus achieving resource recycling.

Marble cone crusher application scenarios