Z-type bucket elevator

The price of the Z-type bucket elevator varies significantly depending on factors such as model, material, handling capacity, lifting height. Its price ranges from $200 to $4,800.

Power: 750 watts

Dimensions: 2100x730x2350mm/customizable

Width or diameter: 500mm/customizable

Voltage: 220/380V

Bucket volume: 0.15

Lifting height: 1.9 meters

What is Z-type bucket elevator?

Z-type bucket elevator is suitable for continuous lifting and conveying of powdered, granular and small block materials, such as flour, sand, grain, plastic granules, etc. Its handling capacity can be adjusted according to the equipment model and material characteristics, covering the transportation needs of 3-100 cubic meters/hour. The hopper capacity is available in a variety of specifications, ranging from 1 liter to 6.5 liters. The materials include plastic, carbon steel and stainless steel, which can flexibly match the fluidity and process requirements of different materials.

Z-type bucket elevator is responsible for conveying bulk materials from low to high positions in industrial production. Its design structure enables it to realize the process of horizontal feeding, vertical lifting and horizontal discharging, forming a "Z" or "C" shaped material path. In terms of conveying distance, it is mainly responsible for lifting in the vertical direction, and the common lifting height ranges from several meters to tens of meters, and also includes the necessary horizontal feeding and discharging sections.

What are the advantages of Z-type bucket elevator?

Due to its unique design and working principle, Z-type bucket elevator has many significant advantages in material transportation. Z-type bucket elevator has become a reliable vertical conveying solution in many industries due to its gentle handling of materials, flexible layout, good sealing, high degree of automation and easy maintenance.

Low crushing rate, protecting material integrity: Z-type bucket elevator adopts inflow feeding method, and the material enters the hopper gently, reducing the impact and friction on the material during the entire lifting process, so the crushing rate is very low. This is especially important for fragile or collision-intolerant materials (such as potato chips, melon seeds, peanuts, cereals, puffed foods, etc.), which can effectively maintain the integrity of the material.

Flexible layout and space saving: Z-type bucket elevator has the characteristics of horizontal and vertical conveying, and can realize the "horizontal-vertical-horizontal" Z-shaped conveying path. This compact design greatly saves floor space and is especially suitable for production environments with limited space. It usually has a feed port at the lower end and a discharge port at the upper end, and multiple feed ports and discharge ports can be customized according to production needs to achieve multi-point feeding and multi-point unloading, meet the needs of multi-bin feeding, and thus save equipment procurement costs.

Good sealing: Z-type bucket elevator adopts a fully enclosed casing design and is usually equipped with a negative pressure circulation loading and unloading system, which effectively avoids dust flying when the equipment is running. This is especially important for industries with high hygiene requirements (such as food processing).

High degree of automation and significant efficiency: Z-type bucket elevator can be seamlessly connected with other equipment such as vibrating feeders and combination scales to form a fully automated material conveying system. It can achieve continuous material lifting and conveying, regardless of the lifting height, effectively improve production efficiency, and reduce the instability caused by manual operation.

Easy to maintain and clean: Many Z-type bucket elevators are designed with easy-to-remove inspection covers and inspection windows, and the hoppers are often designed with quick-release designs for easy and quick installation or removal.

Reliable and durable: Z-type bucket elevators are usually made of high-quality materials and have a solid structure that can withstand strict operating requirements, ensuring long-term reliability and durability of the equipment and reducing operating costs.

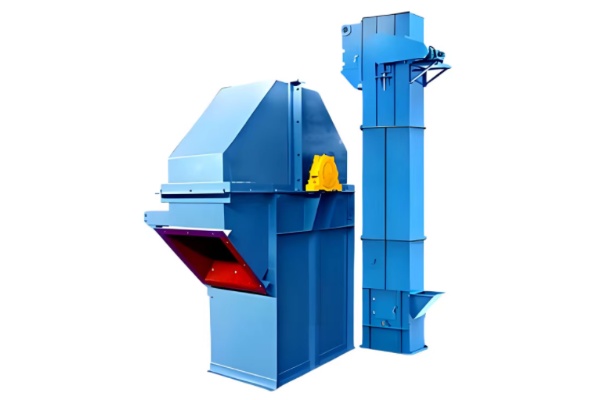

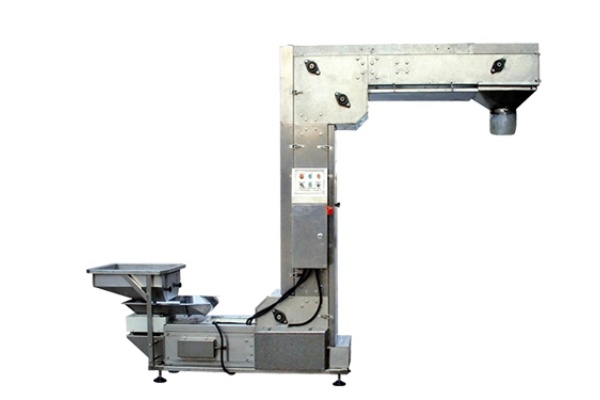

Picture display of Z-type bucket elevator

Parameters of Z-type bucket elevator

| Model | CTZD-2L | CTZD-5L | CTZD-7L |

| Capacity/Bucket | 2L | 5L | 7L |

| Speed | 9-11m/min | 9-11m/min | 9-11m/min |

| Processing Capacity | 4-8m³/h | 12-15m³/h | 15-17m³/h |

| lifting Height | Customized | Customized | Customized |

| Power | 0.75-7.5KW | 0.75-7.5KW | 0.75-7.5KW |

| Box Sized | 628x420 | 750x500 | 820x650 |

| Model | Capacity | Bucket Volume | Number of discharge ports | Lifting Height | Power | Voltage | Construction materials | Bucket materials |

| HYZT-2L | 0-6m³/h | 2L | Single | Up To 50m | 0.75-22KW | As per order | Carbon steel,SS304/316 | Food grade PP or ABS, SS304/316, Carbon steel |

| HYZT-3L | 0-8m³/h | 3L | Single or Multi-discharge Port | Up To 50m | 0.75-22KW | As per order | Carbon steel,SS304/316 | Food grade PP or ABS, SS304/316, Carbon steel |

| HYZT-5L | 0-12m³/h | 5L | Single or Multi-discharge Port | Up To 50m | 0.75-22KW | As per order | Carbon steel,SS304/316 | Food grade PP or ABS, SS304/316, Carbon steel |

| HYZT-7L | 0-15m³/h | 7L | Single or Multi-discharge Port | Up To 50m | 0.75-22KW | As per order | Carbon steel,SS304/316 | Food grade PP or ABS, SS304/316, Carbon steel |

| HYZT-10L | 0-20m³6/h | 10L | Single or Multi-discharge Port | Up To 50m | 0.75-22KW | As per order | Carbon steel,SS304/316 | Food grade PP or ABS, SS304/316, Carbon steel |

How does a Z-type bucket elevator work?

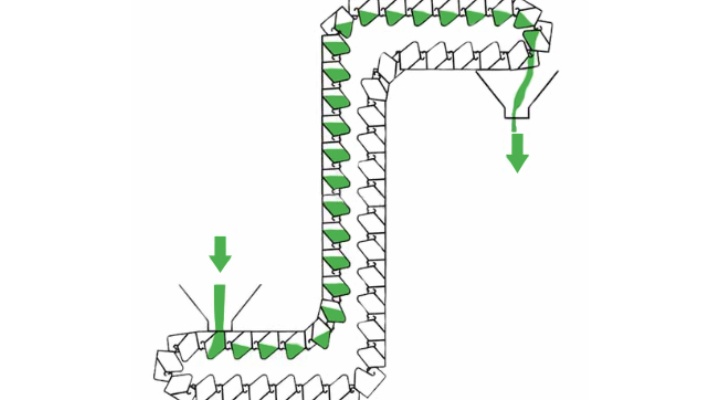

Z-type bucket elevator (also often called Z-type elevator or Z-type conveyor) is a device that continuously lifts bulk materials vertically. It is named "Z-type" because its overall shape resembles the letter "Z". It completes material transportation through a combination of horizontal feeding, vertical lifting, and horizontal discharge. The working principle of the Z-type bucket elevator mainly depends on the synergy of the drive device, hopper, chain or belt, and frame.

Material feeding: Bulk materials (such as grains, particles, powders, blocks, etc.) enter through the feed port located at the bottom or lower horizontal section of the equipment. In the horizontal feeding section, the material will naturally fall into the hopper fixed on the chain or belt. These hoppers are usually tilted or placed horizontally to accommodate the material.

Vertical lifting: The drive device (usually a motor driving a sprocket or roller through a reducer) drives the chain or belt to run upward at a certain speed. The hopper fixed on the chain or belt moves upward accordingly, lifting the material inside from a low place to a high place. During this vertical lifting process, the hopper keeps its opening upward to ensure that the material does not overflow.

Material unloading: When the hopper moves to the top of the elevator (upper horizontal section), the material is unloaded through a specific unloading method.

Centrifugal unloading: This method generates centrifugal force through high-speed operation to throw the material out of the hopper. It is suitable for powdery, granular, small block, dry and fluid materials.

Gravity unloading: When the hopper is turned over or tilted, the material slides out naturally under the action of gravity. It is suitable for blocky, sticky or abrasive materials.

Mixed unloading: It combines the characteristics of centrifugal and gravity unloading and is suitable for a variety of materials.

Reciprocating: After unloading, the empty hopper will continue to run downward with the chain or belt, return to the bottom of the Z-type, and enter the feeding area again, and so on, to achieve continuous material lifting and conveying.

What are the configurations of Z-type bucket elevator?

As a material vertical conveying equipment, the configuration of Z-type bucket elevator can be elaborated in detail from two main aspects: structural composition and peripheral equipment that can be used in combination.

Structural composition of Z-type bucket elevator

Drive device: It is the power source of the elevator, usually composed of motor, reducer, coupling (or chain/belt drive) and brake. The motor provides power, the reducer reduces the speed and increases the torque, and drives the sprocket or drum to rotate. The brake is used to prevent the chain or belt from reversing during shutdown to ensure safety.

Transmission parts (chain or belt): Most Z-type elevators use double chain transmission. The chain is made of high-strength steel, which is wear-resistant and has strong load-bearing capacity. The chain is driven by the sprocket, and the operation is stable and reliable. Some elevators also use belts, which have the characteristics of low noise and smooth operation.

Hopper: This is the component that directly carries and transports materials. It is usually made of food-grade plastics (such as PP, ABS), stainless steel or carbon steel. The specific material depends on the nature of the transported material (corrosiveness, abrasiveness, hygiene requirements, etc.).

Casing (or closed cover): It is used to enclose the entire elevator system, protect the internal components from the external environment, and prevent dust from spilling out during the transportation of materials.

Feed section: Located at the bottom or lower horizontal section of the elevator, it is the entrance for materials to enter the elevator. Usually equipped with a feed hopper or interface to connect to upstream equipment.

Discharge section: Located at the top or upper horizontal section of the elevator, it is the outlet for materials to be discharged from the elevator. It can be designed as a single-point discharge or multi-point discharge, and the discharge path is controlled by an electric or pneumatic valve.

Z-type bucket elevator can be used in combination with peripheral equipment

Silo/storage tank: Store bulk materials to be lifted, provide a continuous and stable material supply for the elevator, and avoid frequent feeding or material interruption. The silo is usually located above the feed port of the elevator, and the material is fed into the elevator by gravity or screw conveyor.

Vibrating feeder/screw feeder: accurately control the flow of materials into the elevator to ensure that the elevator runs evenly and stably to avoid blockage or overload. Placed below the silo and above the feed port of the elevator as an intermediate feeding link.

Packing machine: quantitatively pack the materials after lifting, which can be a vertical packaging machine, bag packaging machine, canning machine, etc. The Z-type elevator lifts the materials above the hopper of the packaging machine, and the packaging is completed through the weighing and filling system of the packaging machine.

Mixer/blender: mix multiple materials evenly, the elevator can convey the mixed materials to the next process, or lift materials of different components into the mixer separately. The elevator can convey the mixed finished product to the packaging machine, or lift the ingredients to the feed port above the mixer.

Screening machine/vibrating screen: classify materials, remove impurities or remove large particles. The screening machine can be placed at the front end of the elevator (to pre-process the raw materials) or at the back end (to re-screen the finished products after lifting).

Dryer/Cooler: Temperature treatment is performed before and after the material is lifted, such as drying wet materials or cooling high-temperature materials. The elevator can be connected to the discharge port of the dryer or cooler to transport the processed materials to the next link.

What are the applications of Z-type bucket elevator?

As a universal vertical conveying equipment, Z-type bucket elevator is widely used in many scenarios where bulk materials need to be lifted. It is not limited to a specific industry, but as a reliable material handling solution, it can handle materials of various forms and characteristics. Here are some application scenarios of Z-type bucket elevator:

Vertical material transportation: Whether the material is powder, granules, small blocks, or flakes, as long as it needs to be lifted from a lower height to another higher height, the Z-type elevator can do it.

Multi-point feeding and multi-point discharging: The unique structure of the Z-type bucket elevator enables multi-point feeding and multi-point discharging. This means that it can receive materials at different heights and unload materials to different production lines or containers at different heights. This flexibility is very useful in automated production lines where material diversion or confluence is required.

Buffering and storage: The Z-type elevator can temporarily store a certain amount of material in its hopper to act as a buffer. When the upstream equipment supplies materials too quickly or the downstream equipment has insufficient processing capacity, it can serve as an intermediate link to accumulate materials and avoid stagnation of the production line.

Material lifting and distribution: When the material needs to be lifted to a certain height and then distributed to different packaging machines, mixers, screening machines or other processing equipment according to demand, the Z-type elevator can act as an efficient diverter. Its multi-point discharging feature makes it possible to accurately distribute materials.

Closed conveying, reducing pollution: Since Z-type bucket elevators usually adopt a fully enclosed design, dust spillage and material contamination can be reduced during the conveying process. This is very important for occasions with high requirements for environmental hygiene and material purity, such as the need to avoid the risk of cross contamination or dust explosion.

Improve space utilization: Compared with ramp conveyors or other horizontal conveying equipment, Z-type bucket elevators can save ground space by vertical lifting.

Handling fragile materials: Z-type bucket elevators have relatively smooth lifting and unloading processes for materials, with less impact and wear on materials. They are particularly suitable for conveying fragile particles or block materials such as potato chips, biscuits, and puffed foods, which helps to maintain product integrity.

Applicable materials of Z-type bucket elevator

Z-type bucket elevator can adapt to the lifting needs of various bulk materials due to its gentle conveying method and good sealing. It is particularly suitable for scenes with requirements for material integrity, sanitary conditions or dust control.

Granular materials

Food particles: such as grains (rice, corn, wheat, soybeans), beans, coffee beans, cocoa beans, candies, chocolate beans, nuts (peanuts, almonds, pistachios), potato chips, biscuits, puffed foods, oatmeal, cereal flakes, pet food particles, etc.

Plastic particles: such as PVC, PE, PP and other plastic particles, recycled plastic scraps, etc.

Chemical particles: such as fertilizer particles, desiccant particles, catalyst particles, etc.

Other particles: such as feed particles, seeds, pebbles, sand, coal particles, etc.

Small block materials

Z-type bucket elevator can also effectively handle small and irregular block materials, such as small candies and chocolate blocks. Small pieces of dried fruits and vegetables. Some small industrial waste or recyclables. Small hardware, screws, gaskets, etc.

Powdered materials

Although bucket elevators are mainly used for granular and block materials, by choosing the right bucket design and lifting speed, Z-type bucket elevators can also transport certain powders with good fluidity and low adhesion, and due to its closed structure, it can effectively control dust. For example: food powders such as flour and milk powder. Pharmaceutical powders. Certain chemical powders. Construction material powders such as cement and lime (abrasiveness needs to be considered).

Manufacturers of Z-type bucket elevators

Z-type bucket elevators play a key role in the field of bulk material conveying, and the core competitiveness of its manufacturers is reflected in their customization capabilities. Manufacturers not only provide standardized products, but also provide solutions by understanding the specific needs of customers. Customization capabilities are reflected in multiple aspects. For example, according to the characteristics of different materials (such as abrasiveness, viscosity, density, fragility, corrosiveness, etc.), manufacturers can adjust the material (such as PP, ABS plastic, stainless steel, carbon steel), shape and unloading method (such as centrifugal, gravity, mixed) of the hopper. For fragile materials, a more gentle lifting and unloading design will be adopted to reduce damage; for corrosive materials, corrosion-resistant materials will be selected. According to the actual space limitations of the customer's site, the manufacturer can adjust the height, horizontal section length, inlet and outlet position and direction of the elevator. For example, in a factory with limited floor height, a more compact top drive design may be required; in areas where multiple production lines are staggered, a more flexible inlet and outlet layout needs to be considered. According to the actual throughput requirements of the production line, the manufacturer can accurately calculate and configure the appropriate hopper volume, chain/belt speed and drive power to ensure that the elevator can stably meet the production capacity requirements and avoid overload or inefficiency. For customers who need to meet special environmental requirements such as explosion-proof, clean (food grade), high temperature or low temperature, the manufacturer can provide corresponding explosion-proof motors, sealing structures, special materials or insulation/cooling devices. Based on a detailed demand assessment, the manufacturer will provide a preliminary design plan, including elevator model recommendations, overall dimensions, power configuration, control system integration, etc. Z-type bucket elevator manufacturers can ensure that the equipment provided can not only stably complete material transportation tasks, but also integrate with the customer's overall production system to improve production efficiency.

Z-type bucket elevator case

Z-type bucket elevator is a versatile vertical conveying equipment with a wide range of applications, mainly concentrated in various industrial production scenarios where bulk materials need to be continuously lifted from low to high. For example, in the production line of snack foods such as potato chips, rice crackers, biscuits, and candies, Z-type bucket elevators are often used to lift finished products at the end of the production line from a low position to above the multi-head scale (combination scale). Since these foods are usually fragile, the Z-type bucket elevator uses a gentle lifting method to reduce product damage. The closed casing also ensures the hygiene and safety of food and prevents external contamination. In the processing of nut roasting or baking products (such as bread crumbs and cereals), the Z-type elevator can lift the processed materials to the packaging machine or the storage bin of the next process to achieve continuous production. In the production of plastic products, plastic granules are the main raw materials. Z-type bucket elevator is often used to lift plastic granules from the raw material bin to the hopper of the injection molding machine or extruder, or to lift recycled plastic granules to the processing equipment. Its wear-resistant hopper can also adapt to the characteristics of plastic granules. For some recycled materials such as crushed plastic scraps, wood chips, small metal pieces, etc., the Z-type elevator can also lift them to the equipment for sorting, cleaning or reprocessing. Z-type bucket elevator has become an indispensable vertical conveying solution in many industrial production lines due to its strong adaptability, high conveying efficiency, small footprint and good material protection.

The Z-shaped or C-shaped structure of the Z-type bucket elevator enables it to complete the horizontal feeding, vertical lifting and horizontal discharging of materials in one device, simplifying the complex conveying path. In terms of material handling, the equipment's lifting method for bulk materials is relatively stable, which helps to keep the material shape intact. At the same time, its closed design helps to control dust. These features make the Z-type bucket elevator a choice for material transfer on a variety of industrial production lines.