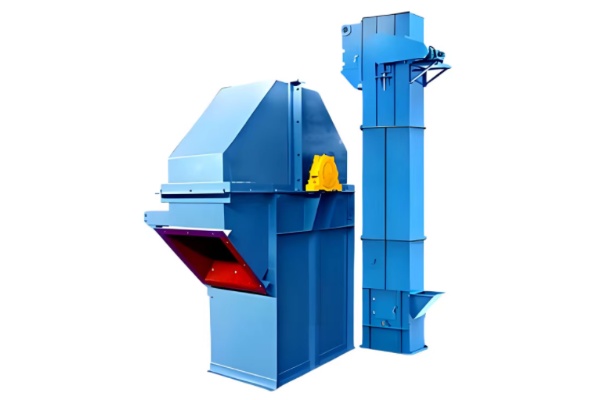

Slag Bucket Elevator

The price of a slag bucket elevator ranges from $300 to $9,000, depending on factors such as the type of equipment, lifting height, handling capacity, material, and brand.

Voltage: 220V, 380V, 440V, 480V

Capacity: 10 ~ 160 T/h

Dimensions (L×W×H): 550mm * 360mm * 8500mm/customized

Belt speed: 1.6m/s

Frame material: stainless steel/alloy

What is Slag Bucket Elevator?

Slag Bucket Elevator are primarily available in two types: chain and belt, to suit different operating conditions. Chain bucket elevators, due to their sturdy structure, are often used to transport hot, abrasive slag. Belt bucket elevators, with their smooth operation and high speed, are suitable for handling less abrasive materials. Different bucket elevator models are designed with full consideration of varying handling capacity and lifting heights. From several tons to hundreds of tons per hour, and from a few meters to tens of meters, corresponding technical solutions are available to ensure continuous material transportation.

What are the types of slag bucket elevators?

Slag bucket elevators are primarily available in two types: chain and belt. Chain bucket elevators are more suitable for handling hot, abrasive, and large slag. Belt bucket elevators, on the other hand, are more suitable for handling less abrasive, cooler slag, and for applications requiring higher conveying capacity and lifting speed.

Chain bucket elevator

Chain bucket elevators use chains to move the bucket. Its advantages include a sturdy structure and the ability to withstand large shock loads, making it ideal for conveying dense, abrasive slag. Furthermore, chains are more heat-resistant than belts in high-temperature environments, making chain bucket elevators commonly used for conveying hot slag.

Lifting Height: Due to the greater load-bearing capacity of chains, some heavy-duty chain bucket elevators can reach heights of 50 meters or even higher, with some models reaching 75 meters.

Capacity: Generally speaking, chain bucket elevators can handle capacities ranging from a few tons per hour to thousands of tons per hour. For example, some heavy-duty chain bucket elevators can reach capacities of 600 m³/h or even 1,000 m³/h. This makes them particularly suitable for conveying large, dense, and abrasive materials.

Speed: Due to the weight and structural limitations of the chain, its operating speed is typically slow, typically between 1.0 and 1.5 m/s.

Belt Bucket Elevator

Belt bucket elevators use a high-strength belt as a traction element to move the bucket. Its advantages include smooth operation, high speed, and low noise. The belt's lighter weight allows for increased lifting height and conveying capacity. However, belts are generally less wear- and heat-resistant than chains, making them more suitable for conveying less abrasive, cooler materials.

Lifting Height: The lifting height of a belt-type bucket elevator is generally limited by the belt's strength. It can reach 30 to 50 meters, with some specialized designs reaching 80 meters.

Capacity: The handling capacity of a belt-type bucket elevator can range from tens of tons per hour to 1,500 m³/h or even higher.

Speed: Belt-type bucket elevators typically operate much faster than chain-type elevators, typically ranging from 1.5 to 3.5 m/s or even higher.

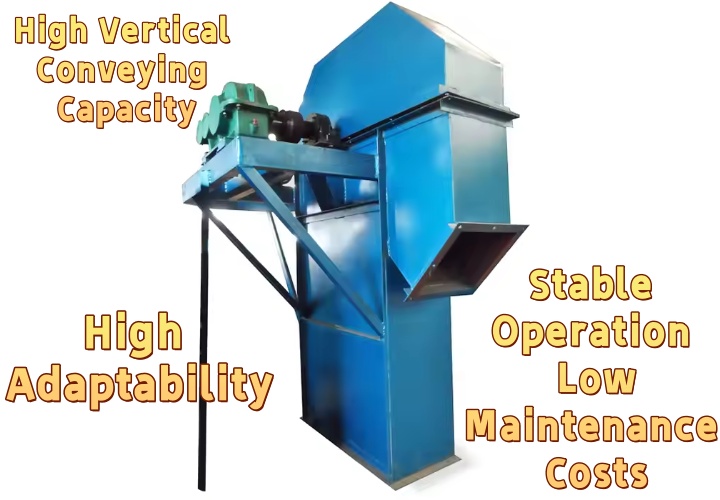

What are the advantages of the slag bucket elevator?

The widespread use of the slag bucket elevator is primarily due to several significant advantages. The advantages of the slag bucket elevator lie in its ability to achieve stable and continuous vertical conveying of slag with a small footprint, stable operation, and a high degree of automation, while also adapting to harsh working conditions.

High Vertical Conveying Capacity: The slag bucket elevator's advantage lies in its ability to achieve high vertical conveying heights and large throughputs within a compact footprint. It lifts slag from a lower level to a higher level, conveniently transferring the material to silos, bins, or other processing equipment, thereby optimizing production processes and space utilization.

Compact Structure and Small Footprint: Bucket elevators convey slag vertically, requiring very little floor space. This is advantageous for factories or production lines with limited space, effectively conserving valuable land resources.

Stable Operation and Low Maintenance Costs: Whether chain or belt type, bucket elevators have a relatively simple and robust structure. When properly installed and maintained, they operate remarkably stably with a low failure rate. Routine maintenance primarily focuses on checking the tension of the chain/belt, checking the wear of the bucket, and lubricating components.

High Adaptability: The slag bucket elevator can withstand a variety of harsh working conditions. Specially designed buckets and chains/belts can withstand the impact and friction of highly abrasive materials like slag, ensuring the equipment's longevity. Chain-type bucket elevators effectively transport high-temperature slag, preventing belt damage due to high temperatures. Bucket elevators typically feature an enclosed casing, effectively preventing dust from escaping.

Slag Bucket Elevator Parameters

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

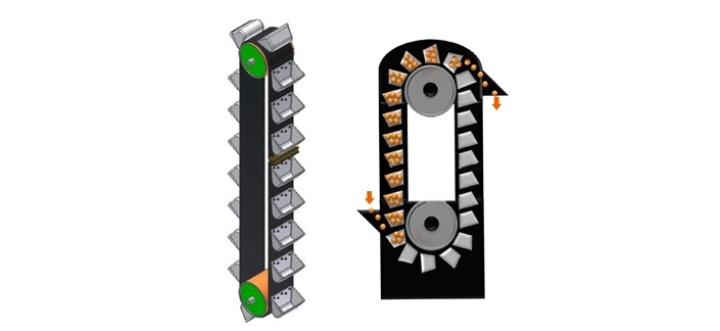

How does a slag bucket elevator work?

A key piece of equipment in mineral processing and industrial production, the slag bucket elevator operates on a simple principle. It primarily consists of a head, barrel, base, transmission, traction mechanism (chain or belt), and hopper. The entire system functions as a vertical circulation system, lifting slag from a low level to a high level. The operation of a bucket elevator can be divided into several key steps. First, the feed is introduced: slag is fed through the feed port at the bottom of the base. The slag accumulates at the base, awaiting loading into the hopper. Next comes loading and lifting. When the traction member (chain or belt) begins moving under the drive mechanism, the attached hopper enters the material pile at the bottom of the machine base. The hopper acts like a shovel, scooping up material from the bottom. As the traction member continues its upward motion, the hopper, filled with slag, is lifted vertically along the barrel. Next comes unloading. When the hopper reaches the top of the machine head, the traction member begins to pivot around the drive wheel or sprocket. During this pivoting process, gravity and centrifugal force combine to "dump" the slag from the hopper, dumping it through the discharge port into a designated silo or the next processing facility. Finally, the circulation process begins. The empty hopper continues its downward motion with the traction member, returning to the bottom of the machine base for the next loading and lifting step. This continuous cycle ensures consistent slag transportation. The entire system utilizes precise transmission and tensioning mechanisms to ensure stable operation of the chain or belt, preventing slippage or derailment. The enclosed design of the machine casing not only effectively prevents dust from escaping but also protects the internal transmission components. Whether using a sturdy chain or a high-speed belt, the Slag Bucket Elevator utilizes physical circulation to achieve maximum material transport efficiency at a minimal space cost.

What are the uses of the Slag Bucket Elevator?

The Slag Bucket Elevator is primarily used to vertically lift and convey various bulk, granular, and powdered materials. It is a stable, continuously operating material handling device capable of conveying materials from a lower level to a higher level within a limited space, thereby automating and streamlining production processes. Its specific application scenarios can be summarized as follows:

Vertical Material Lifting: Bucket elevators can continuously and stably lift powdered, granular, or small bulk materials from a lower level to a higher level. This vertical conveying method saves space and is a critical component in many production lines and storage systems.

Material Storage and Distribution: In industrial production, bucket elevators are often used to lift materials to elevated silos, bins, or buffer tanks. This not only facilitates material storage but also facilitates subsequent processes such as weighing, mixing, packaging, or distribution, ensuring a smooth production process. Process Integration and Automation: Bucket elevators can serve as a key component in automated production lines. When used in conjunction with other equipment such as conveyors, feeders, and packaging machines, they enable unmanned, continuous material transportation, significantly improving production efficiency.

Material Sorting and Storage: In material sorting centers or warehouses, bucket elevators can lift different materials into separate bins or silos for classified storage, significantly improving the efficiency and automation of material management.

Price of Slag Bucket Elevator

The price of a slag bucket elevator typically fluctuates significantly depending on factors such as model, configuration, and performance. Generally, prices range from $300 to $9,000. The price of a slag bucket elevator is influenced by a variety of factors. The following are some of the main determining factors. First, the type of bucket elevator. Chain bucket elevators are generally more expensive than belt bucket elevators of the same specifications due to their sturdier structure, higher chain costs, and greater load capacity. Belts are relatively inexpensive and simpler in structure, making them generally more cost-effective. Next are the lifting height and handling capacity. A higher lifting height requires longer chains/belts, more material for the barrel and casing, and stricter overall structural requirements, significantly increasing the price. A larger handling capacity typically requires wider chains/belts, a larger hopper, and a more powerful motor, all of which directly drive up the equipment cost. Finally, the materials and manufacturing process are key factors influencing the price. The materials used for the steel, chains, belts, and hoppers are significant factors influencing the price. For example, components made of wear-resistant, high-temperature-resistant, or stainless steel will cost significantly more than those made of ordinary carbon steel. Advanced manufacturing processes and strict quality control, while increasing initial costs, ensure the equipment's stability and longevity, thus increasing the price accordingly. Furthermore, additional features and customization requirements can affect the price. Requiring additional safety features, explosion-proof design, automated control systems, or custom designs for specific materials can increase the complexity and cost of the equipment, thus impacting the final price.

Slag Bucket Elevators play an indispensable role in mineral processing and industrial material handling. The core of this system is the circular motion of the hopper driven by a traction mechanism, achieving continuous vertical lifting of the slag. Whether it's the durability of a chain-type system or the smoothness and speed of a belt-type system, both are designed to meet the practical material conveying needs of the production line. Equipment design and operating parameters, such as lifting height, handling capacity, operating speed, and adaptability to material characteristics, must be selected and configured based on specific operating conditions.