TB bucket elevator

The price of a TB bucket elevator varies greatly depending on its conveying capacity, lifting height, material and configuration, ranging from US$500 to US$7,500.

Power: 750 watts

Dimensions: 2100x730x2350mm/customizable

Width or diameter: 500mm/customizable

Voltage: 220/380V

Bucket volume: 0.15

Lifting height: 1.9 meters

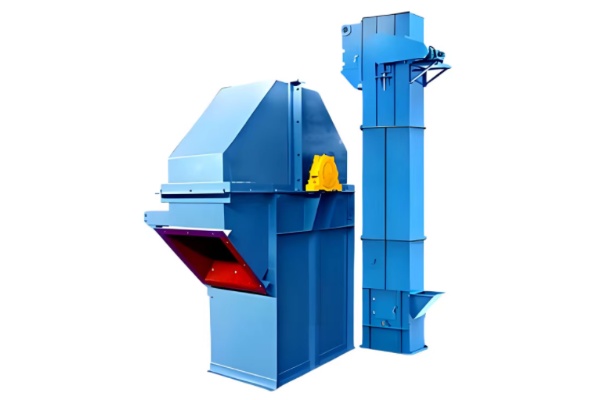

What is TB bucket elevator?

TB bucket elevator is a device used to transport materials vertically from low to high levels. The core feature of this elevator is its plate chain traction mechanism, which makes it adaptable to heavy loads and abrasive materials. Based on the discharge method, TB bucket elevators are generally categorized as centrifugal or gravity to accommodate different material characteristics. Material handling capacity is typically measured in tons per hour, ranging from tens to hundreds of tons, meeting material handling needs of varying scales.

What are the advantages of a TB bucket elevator?

The TB bucket elevator's unique plate chain structure provides high load capacity, wear resistance, a large lifting height, and smooth operation. Compared to other types of bucket elevators, it offers several significant advantages:

High load capacity: The TB bucket elevator's most prominent advantage is its high load capacity. Its traction mechanism utilizes high-strength plate chains, rather than traditional belts or ordinary chain links, allowing it to withstand greater tensile forces. Therefore, TB bucket elevators can easily handle materials with high specific gravity, high density, or large lumps, such as ore and gravel, making them ideal for use in heavy industry and mining.

Wear-resistant and long service life: TB bucket elevators offer a particularly strong durability advantage when handling highly abrasive materials. The plate chain, composed of a series of sturdy plates, offers far superior wear resistance to belts. Furthermore, the connection between the hopper and the chain is more secure and reliable, making it less susceptible to damage from material impact. This robustness significantly extends the equipment's service life and reduces the frequency of maintenance and replacement.

High lifting height: Thanks to the plate chain's strong load-bearing capacity, TB bucket elevators can achieve greater lifting heights. TB bucket elevators are an ideal choice for applications requiring materials to be lifted from the ground to heights of tens or even hundreds of meters. This makes them ideal for vertical material conveying in large silos, bins, or elevated production lines.

Excellent operational stability: TB bucket elevators utilize a sprocket meshing drive, which is less prone to slippage and provides smooth and reliable operation. This not only ensures continuous and stable material conveying, but also reduces equipment failure rates, providing reliable production support.

TB bucket elevator parameters

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

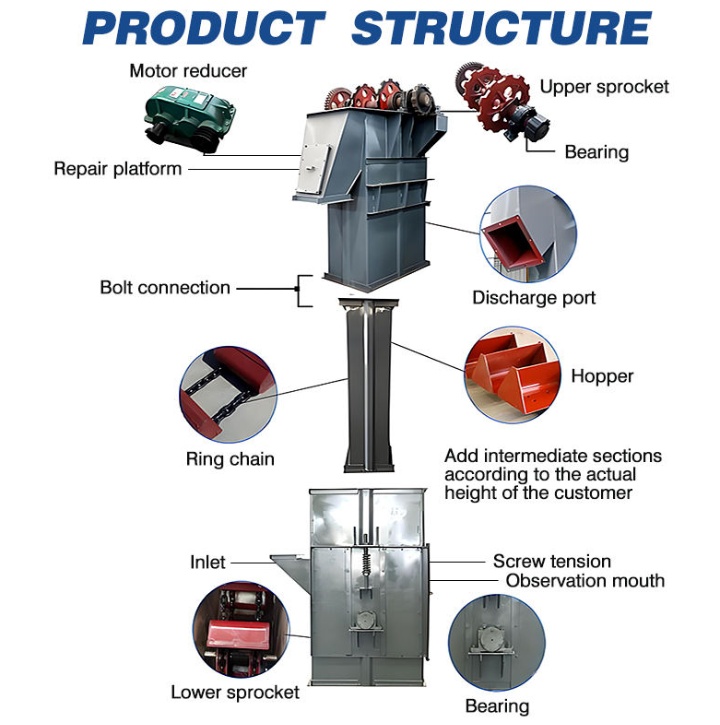

What are the structural features of a TB bucket elevator?

TB bucket elevator is a type of vertical conveying equipment. Its structure primarily consists of the following components. First, the head section, which is the top of the elevator, typically includes the transmission mechanism, which is the elevator's power source. It consists of a motor, a reducer, and a drive roller (or sprocket), driving the plate chain and hopper. The discharge port is where materials are discharged after reaching the head section. The access door is used for routine inspection and maintenance. Next, the base section, which is the bottom of the elevator, typically includes the feed port, where materials enter the elevator. The tensioning device adjusts the tension of the plate chain to ensure smooth operation and prevent slippage or deviation. The base supports the entire base and is anchored to the foundation. The intermediate casing (hoisting section) is the main body of the elevator, connecting the head and base. Depending on the lifting height, the intermediate casing is composed of multiple standard sections. The casing protects internal components and prevents material leakage. It is typically enclosed to reduce dust contamination. In some designs, guide rails guide and stabilize the plate chain. The plate chain, a key component of the TB bucket elevator, is also a core component. It consists of a series of high-strength, wear-resistant chain plates and pins, capable of withstanding greater tensile forces and providing the foundation for the conveyor's high load capacity. The hopper carries and lifts the material. It is bolted or welded to the plate chain. The shape and size of the hopper are determined by the material characteristics and the desired conveying volume.

What are the uses of the TB bucket elevator?

Due to its sturdy plate chain structure, the TB bucket elevator plays a vital role in various applications requiring vertical conveying of heavy, highly abrasive materials. Its applications are primarily concentrated in the following areas:

Mining and metallurgy: This is a typical application area for the TB bucket elevator. In mining, it is used to lift materials such as ore, coal, and slag from the mine floor to the surface, or to transport materials to various processing stages. In the metallurgical industry, TB bucket elevators are used to transport sinter, coke, and iron ore fines. Their high load capacity makes them easy to handle these heavy, abrasive materials. Construction and Building Materials: TB bucket elevators are also widely used in the construction and building materials industries. They are commonly used in cement production lines to transport raw materials, cement clinker, limestone, and other materials to elevated silos, grinding mills, or packaging lines. In aggregate production, in sand and gravel production lines, they are used to vertically lift crushed stone and sand to screening machines or finished product silos. In concrete mixing plants, they are used to transport raw materials such as aggregates and cement to mixers.

Chemical and Power: In the chemical and power industries, TB bucket elevators are used to transport various powdered and granular materials. Their enclosed structure helps reduce dust pollution. Chemical raw material transportation: They transport various chemical raw materials such as fertilizers, salts, and alkalis to elevated locations for mixing, reaction, or storage. In power plants, coal transportation: In coal-fired power plants, they are used to lift coal from the coal yard to the boiler room.

Grain and Feed: Although known for its heavy-load capacity, TB bucket elevators are also used in the grain and feed industries, particularly for large-volume, high-intensity conveying. It can be used to lift materials such as grain, feed, and oilseeds, ensuring the continuity of the production process.

TB Bucket Elevator Price

The price of a TB bucket elevator isn't fixed; it's influenced by a variety of factors, ranging from tens of thousands to hundreds of thousands, or even millions. Many key factors influence price, including conveying capacity and lifting height, which are the primary influencing factors. Conveying capacity (tons of material conveyed per hour) and lifting height directly determine the required power, chain strength, hopper size, and machine structure. Greater conveying capacity and higher lifting height require stronger and larger components, naturally increasing equipment costs. Conveyor belt material: Prices vary significantly depending on the material. Ordinary steel chains are relatively inexpensive, while special alloy steel or stainless steel chains used in specialized environments (such as high temperatures and corrosive environments) have higher manufacturing costs, increasing the price of the equipment accordingly. The cost of single-chain and double-chain elevators varies depending on the structural type and configuration. Double-chain elevators, due to their more stable load-bearing capacity, are generally more expensive than single-chain elevators. Additionally, additional features can affect the price, such as the housing material (standard carbon steel is cheaper, while corrosion-resistant stainless steel is more expensive), drive method (special configurations such as variable-speed motors and explosion-proof motors can increase costs), and safety systems (safety features such as emergency stop switches, anti-slip sensors, and tear protection are also factored into the total price).

TB Bucket Elevator Manufacturers

The TB bucket elevator, with its sturdy plate chain structure, offers significant advantages when handling heavy, abrasive materials. However, achieving its full potential relies on the manufacturer's customization capabilities. These capabilities are typically reflected in the following areas:

Customization based on material properties: The core of a TB bucket elevator is material transportation, and the physical and chemical properties of different materials vary significantly. Professional manufacturers can provide customized solutions based on the customer's specific material characteristics, such as specific gravity, particle size, abrasiveness, temperature, and humidity. For example, for highly corrosive materials, manufacturers use stainless steel or special coatings for the machine body and chain. For high-temperature materials, they use special heat-resistant alloy steel. For materials prone to adhesion, they design specific hopper shapes and cleaning devices to ensure smooth material discharge and minimize residue.

Customization based on operating conditions: Equipment performance is influenced not only by the material but also by the operating environment. Manufacturers' customization capabilities are reflected in their ability to optimize the equipment design based on specific operating conditions, such as conveying capacity, lifting height, installation space, and environmental requirements. For example, for confined factory spaces, manufacturers can design more compact elevators. For dusty or explosive environments, they can provide explosion-proof motors and fully enclosed enclosures. For complex applications requiring multiple feeding or discharging points, manufacturers can design appropriate chutes and discharge ports to meet specific production process requirements.

Modular design and personalized configuration: Many leading TB bucket elevator manufacturers adopt a modular design concept. This design allows customers to select and combine different modules and components according to their specific needs, like building blocks. For example, a variety of hopper options are available, including deep, shallow, round, and special shapes, to accommodate diverse material handling needs. Drive system customization allows for the selection of different motor and reducer configurations based on load and speed requirements, even employing variable frequency drive (VFD) speed control for more precise material flow control. Safety and monitoring systems offer optional features such as anti-slip switches, emergency stop switches, anti-jam sensors, and even remote monitoring systems, tailored to customer safety standards and automation requirements.

The TB bucket elevator provides a stable vertical material conveying solution in practical applications. Its plate chain drive structure accommodates diverse material handling requirements and provides a degree of resistance to material abrasion. Its vertical layout helps conserve floor space and adapts to layout constraints within factories or workshops. In daily production operations, the TB bucket elevator ensures continuous material transfer, providing essential support for subsequent processing, storage, or loading. Its operating status is strictly monitored, ensuring smooth material conveying.