Z-type bucket elevator price

Tuesday November-04 2025 17:59:39

The price of a Z-type bucket elevator varies significantly depending on the model, material, handling capacity, lifting height, and degree of customization. Z-type bucket elevator price rangs from $200 to $4,800. From basic carbon steel structures to complex food-grade stainless steel configurations, from lower conveying capacity to handling high-load applications, these differences are directly reflected in the final manufacturing cost. In addition, the choice of traction components (chain or belt), the configuration of the drive system, whether it includes explosion-proof design, and the degree of automation are all important variables that determine its price.

What are the types of Z-type bucket elevators?

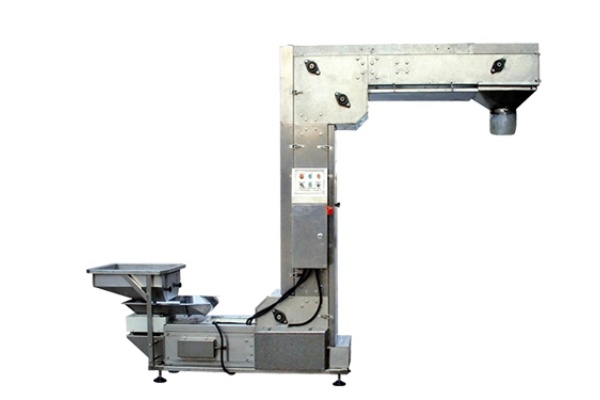

The Z-type bucket elevator is a special bucket elevator. Its unique Z-shaped or C-shaped structure enables it to achieve horizontal feeding, vertical lifting, and horizontal discharge at the same time. Like other bucket elevators, Z-type bucket elevators are also classified according to the type of traction components. These two main types determine their performance characteristics and scope of application.

Chain Z-type bucket elevator

Traction component: Chain is used as the traction component. It is usually a high-strength alloy steel chain, which can be a single chain or double chain configuration. Common ones include plate chain, ring chain, etc. The bucket is fixed to the chain by bolts or other connection methods.

Strong load-bearing capacity: The chain has high strength and wear resistance, and can withstand large tensile and impact loads, so it is suitable for conveying dense, blocky or abrasive materials such as ore, coal, cement clinker, etc.

High temperature resistance: Chain elevators can withstand relatively high material temperatures because metal chains have good temperature tolerance.

Strong structure: The overall structure is usually stronger and suitable for heavy load conditions and harsh environments.

Maintenance: There are wear points at the chain connection, which require regular lubrication and inspection. After wear, it may produce noise and need to be replaced.

Operating speed: Compared with belt type, the operating speed of chain elevators is usually lower.

Belt type Z-type bucket elevator

Traction member: A belt (or tape) is used as a traction member. The belt is usually made of a multi-layer fabric skeleton (such as nylon, polyester) or a steel wire rope core, and is covered with a wear-resistant material such as rubber or PVC. The bucket is fixed to the belt by bolts or clamps.

Smooth operation and low noise: The flexibility of the belt makes it smoother during operation, and the noise and vibration generated are also less.

High operating speed: Belt elevators can usually reach higher operating speeds, thereby achieving a larger conveying volume under the same bucket capacity.

Suitable for light, fine or crushing-sensitive materials: More suitable for conveying grain, feed, plastic particles and other materials with low density, good fluidity and not easy to break.

Good sealing: The gap between the belt and the casing is small, which is conducive to keeping the conveying environment clean and reducing dust spillage.

Z-type bucket elevator price list

| Drive Type | Conveying Capacity / Throughput | Elevating Height | Reference Price (USD) |

|---|---|---|---|

| Belt elevator | For large-scale applications: 50–100 m³/h | Elevating height up to 20–60 m | approx. US$ 5,000 – US$ 30,000 |

| Chain elevator | Small to medium models: 3–12 m³/h | Elevating height generally 2–12 m | approx. US$ 1,000 – US$ 6,000 |

What are the factors affecting Z-type bucket elevator price?

Z-type bucket elevator price is wide, and its price is jointly affected by a series of complex factors, such as material, traction component type, drive system, additional functions, etc. There are many factors affecting Z-type bucket elevator price, which can be summarized as follows:

Material selection

Carbon steel: The price is relatively low and suitable for general material transportation, but its corrosion resistance and wear resistance are not as good as stainless steel.

Stainless steel (such as 304, 316): It is more expensive and has excellent corrosion resistance. It is suitable for industries such as food and chemical industry that have strict requirements on hygiene or corrosion resistance.

Special alloy steel: For special wear or high temperature environments, higher grade alloy steel may be required, and the price will be further increased.

Bucket material: The material of the lifting bucket can be plastic (such as PP, ABS), carbon steel or stainless steel, and the cost of different materials varies greatly. Plastic buckets are light and corrosion-resistant, but have limited load-bearing capacity; metal buckets are strong and durable, but have high weight and cost.

Type of traction component

Belt type: It is usually smoother and quieter than chain type. It is suitable for light, small or crushing-sensitive materials. The initial investment may be relatively low (depending on the belt material and specifications).

Chain type: It has strong load-bearing capacity and wear resistance. It is suitable for heavy, blocky or abrasive materials, but the cost is usually higher than the belt type with the same conveying capacity, and the running noise may be larger. The type of chain (such as plate chain, ring chain) and material will also affect the price.

Conveying capacity and specifications

Conveying volume: The larger the amount of material that needs to be transported per unit time, the larger the required elevator size (such as bucket capacity, screw diameter), motor power and structural strength, and the higher the price.

Lifting height: The higher the lifting height, the longer the chain/belt length and the more casing sections are required, the more complex the structure is, and the price is naturally higher.

Horizontal conveying length: The Z-type elevator includes a horizontal section. The longer the horizontal conveying distance, the longer the equipment length, and the higher the cost.

Bucket size and spacing: The larger the bucket and the denser the spacing, the stronger the conveying capacity, but the cost will also increase.

Drive system

Motor power: The conveying capacity and lifting height determine the required motor power. The larger the power, the higher the motor price.

Reduce machine brand and type: Well-known brands and high-performance reducers are more expensive, but have longer reliability and life.

Control system: Whether it contains automatic control functions such as variable frequency speed regulation, overload protection, material level detection, and fault alarm, all of which will increase the cost.

Choose a suitable Z-type bucket elevator, and its cost structure needs to match the specific working conditions. This involves an accurate assessment of the physical properties of the material to be handled, including its density, abrasiveness and fluidity, to determine the appropriate material and structural strength. At the same time, the installation space of the equipment on site, the expected material conveying volume and the vertical lifting height are all key parameters that determine its size and configuration. Ultimately, Z-type bucket elevator price reflects its investment in design, materials, manufacturing processes and possible auxiliary functions.