Food Grade Bucket Elevator

The price of food-grade bucket elevators varies significantly depending on factors such as their material, conveying height,capacity. Its price range is US$300 to US$8000.

Voltage: 220V, 380V, 440V, 480V

Capacity: 10 ~ 160 T/h

Dimensions (L×W×H): 550mm * 360mm * 8500mm/customized

Belt speed: 1.6m/s

Frame material: stainless steel/alloy

What is Food Grade Bucket Elevator?

Food Grade Bucket Elevator are material handling equipment designed to smoothly transport various materials from low to high locations. These devices are typically constructed of materials such as stainless steel or engineered plastics to meet stringent hygiene standards. Bucket elevators vary in capacity and conveying distance depending on the model and configuration, typically handling several to tens of tons of material per hour, and conveying distances ranging from a few meters to dozens of meters. The design of these devices focuses on ensuring that materials remain intact and free of contamination during the lifting process, while also ensuring smooth flow of production processes without occupying additional horizontal space.

What are the types of food grade bucket elevators?

Food grade bucket elevators must meet stringent hygiene standards, making their material selection crucial. Currently, the most common food grade bucket elevators are made of stainless steel and engineered plastics. The following is a detailed introduction to the two types of bucket elevators:

Stainless Steel Bucket ElevatorAdvantages

Corrosion Resistance: Resists corrosion from most food ingredients, seasonings, and cleaning agents, ensuring long-term, stable operation.

Easy to Clean: The smooth surface resists material residue, making it easy to clean and disinfect, effectively preventing cross-contamination and bacterial growth. Durability: High mechanical strength, capable of withstanding heavy loads, suitable for conveying a variety of materials.

High-Temperature Resistance: Suitable for high-temperature environments, such as in production lines requiring steam sterilization or high-temperature treatment.

Disadvantages:

Higher Cost: Stainless steel equipment is more expensive to manufacture than plastic equipment.

Heavy Weight: The equipment itself is heavier, requiring more installation and maintenance.

Engineering plastic bucket elevators are typically designed for specific materials or production environments. Common engineering plastics include nylon (PA), polyethylene (PE), and polyurethane (PU).

Advantages:

Light Weight: The overall weight of the equipment is low, making it easy to install and move.

Abrasion Resistance: Certain engineering plastics, such as nylon, have excellent wear resistance and are suitable for conveying highly abrasive materials.

Self-Lubrication: Some plastic materials have self-lubricating properties, which reduce friction and noise.

Lower Cost: Typically less expensive than stainless steel equipment.

Disadvantages:

Low Mechanical Strength: Compared to stainless steel, plastics have lower load-bearing capacity and impact resistance. Poor Heat Resistance: Not resistant to high temperatures and unsuitable for high-temperature or steam sterilization environments.

Aging: Plastic materials may age and become brittle after long-term use.

What are the advantages of food grade bucket elevators?

Food grade bucket elevators play a vital role in food production. Their primary advantage lies in their ability to meet stringent hygiene standards and material handling requirements. Their key advantages are reflected in the following aspects:

High Hygiene: This is the core advantage of food grade bucket elevators. Their design and materials are designed to prevent bacterial growth and cross-contamination.

Smooth Surface: The smooth, non-porous surfaces of stainless steel and engineered plastics are less susceptible to the accumulation of material residue, making them easy to clean and disinfect.

No Dead Space Design: The interior of the equipment features rounded transitions and no exposed bolts or screws, reducing dead spaces where material can accumulate.

Easy Disassembly and Cleaning: Many models feature quick-disassembly features, facilitating deep cleaning and maintenance between production runs.

Vertical Conveying: Bucket elevators excel at conveying granular, powdered, or bulk materials vertically, saving valuable production space. High Flow Rate: Able to transport large quantities of material at high speeds and flow rates, meeting the needs of large-scale production lines.

Reduced Material Breakage: Compared to other conveying methods, bucket elevators lift materials more smoothly, minimizing breakage during conveyance. This is particularly important for conveying fragile foods such as cereals and snacks.

Durable and Easy Maintenance: Food grade bucket elevators are typically constructed of corrosion-resistant, high-strength materials.

Corrosion Resistance: Stainless steel resists corrosion from food ingredients, seasonings, and various cleaning agents, extending the equipment's service life.

Modular Design: Many devices utilize a modular structure, making installation, disassembly, and replacement of damaged components easy, significantly reducing maintenance costs and time.

Food Grade Bucket Elevator Parameters

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

How does a food grade bucket elevator work?

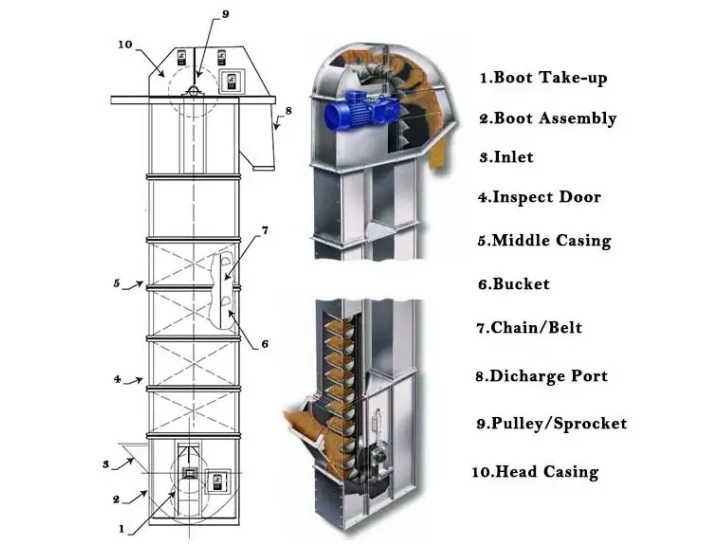

The operating principle of a food grade bucket elevator can be simply summarized as "scoop, lift, and discharge." The core of the entire device is a motor-driven closed-loop transmission system, typically a chain or belt, with a series of uniquely shaped "hoppers" evenly mounted on top. During feeding, when the equipment is in operation, the bottom inlet receives the material to be conveyed. These materials (such as grains, candy, nuts, flour, etc.) fall into the bottom casing. As the drive system (belt or chain) rotates, the hopper mounted above passes the bottom, scooping up the material from the bottom like a small shovel. Driven by the motor, the filled hopper is smoothly carried along the interior of the casing to the top. The entire process is continuous and closed-loop, ensuring that the material does not spill during conveying. When the hopper reaches the top, it tilts due to the flexing of the drive system. Depending on the type and design of the equipment, the material is discharged into the top outlet by centrifugal, gravity, or mixed methods. In centrifugal conveyors, the high-speed rotation of the chain or belt at the top ejects the material from the hopper, making it suitable for conveying granular and powdered materials. In gravity conveyors, the equipment operates at a slower speed, and the hopper naturally tilts under the action of gravity, causing the material to pour out. This is suitable for conveying fragile or lumpy materials. The empty bucket, once discharged, continues its cycle by returning to the bottom of the conveyor belt, ready for the next round of scooping and lifting. This cycle repeats, achieving continuous vertical material conveying. To meet the strict hygiene requirements of the food industry, food grade bucket elevators are typically constructed of stainless steel or engineered plastics and designed with an easy-to-clean structure to ensure clean materials throughout the conveying process and prevent cross-contamination.

What are the applications of food grade bucket elevators?

Due to their high efficiency and hygienic properties, food grade bucket elevators are widely used in many scenarios requiring vertical material conveying, such as feeding materials into mixing, weighing, or packaging equipment. In many production lines, bucket elevators are located at the beginning or middle of the production process. They lift raw materials (such as grains, flour, sugar, and spices) from floor silos to the feed inlets of mixers, automatic weighing machines, or packaging machines, ensuring continuous production flow. For fragile foods such as chips, cookies, and snacks, bucket elevators, with their smooth lifting method, effectively reduce material breakage during conveying and maintain product integrity. Multihead weighers and metering equipment require a continuous supply of material for packaging lines. Bucket elevators lift materials (such as nuts, candy, and coffee beans) from the ground level to the hopper above the multihead weigher, enabling accurate metering and rapid packaging. They also connect production lines at different heights. In large production facilities, different production equipment may be located on different floors or at different heights. Bucket elevators serve as vertical bridges, transporting materials from lower equipment to higher equipment, optimizing space layout and improving production efficiency. They handle a variety of materials, including granules, powders, and lumps. Whether it's fine flour, granular grains, or lumps of candy, bucket elevators can be adjusted with different bucket shapes and operating speeds to accommodate a variety of material conveying needs.

Food Grade Bucket Elevators connect different process stages in various production environments. In practical applications, they lift raw materials from the ground or storage silos to elevated workstations such as mixers, packaging machines, or metering equipment. Their operation enables continuous vertical movement of materials, streamlining material handling processes. The application of this type of equipment helps consolidate production space and standardize material handling processes. The selection and configuration of equipment must be considered based on the physical properties of the materials being handled and the specific layout of the production line to ensure compatibility with existing production processes, thereby achieving stable and reliable material handling.