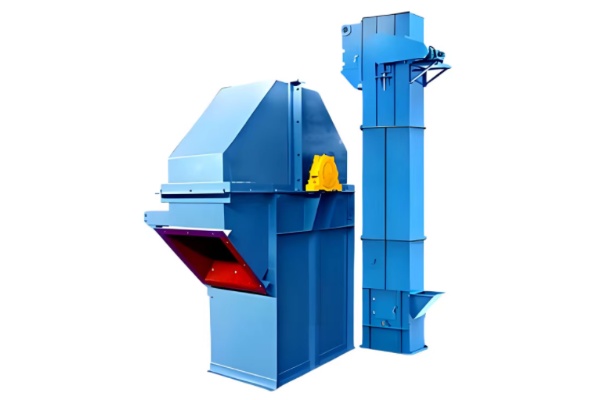

Chain bucket elevator

The price of a chain bucket elevator varies greatly depending on its conveying capacity, lifting height, material and configuration, ranging from $300 to $7,000.

Power: 750 watts

Dimensions: 2100x730x2350mm/customizable

Width or diameter: 500mm/customizable

Voltage: 220/380V

Bucket volume: 0.15

Lifting height: 1.9 meters

What is Chain bucket elevator?

The main function of a Chain bucket elevator is to lift granular, bulk, or powdered materials to a predetermined height. Depending on the discharge method and chain structure, this equipment comes in various types, including centrifugal, gravity, single-chain, and double-chain. Each type has its own specific application focus, adapting to the needs of different materials and working conditions. During operation, the elevator has a specific capacity specification, usually measured in tons transported per hour, ranging from a few tons to hundreds of tons.

What are the types of chain bucket elevators?

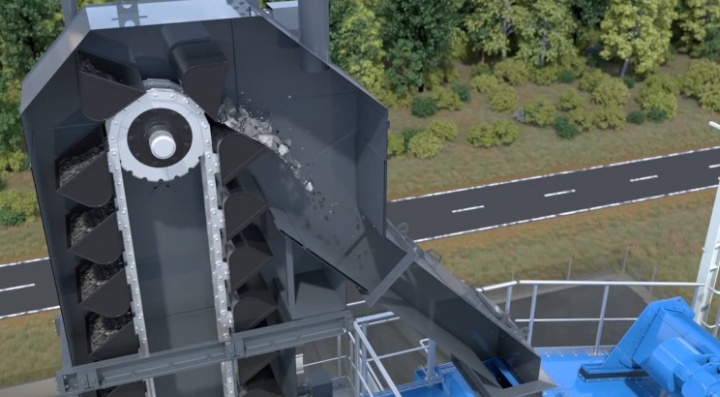

A chain bucket elevator is a device that lifts materials vertically using a chain and a hopper. Its types are primarily categorized by the discharge method and chain structure. Common types include centrifugal, gravity, combined, single-chain, and double-chain.

Classification by Discharge Method

Centrifugal discharge: This type of elevator operates at a high speed. Material passes through a high-speed hopper and is thrown out by centrifugal force into the discharge port. This offers high speed and a high transport capacity. Suitable for conveying powdered, granular, and small, fluid, low-density, non-abrasive or semi-abrasive materials such as coal, gravel, and cement.

Gravity discharge: This type of elevator operates at a relatively slow speed. As the hopper passes over the top sprocket, the material falls naturally from the discharge port under its own gravity. This provides smooth operation and minimizes impact on the material. It is suitable for conveying abrasive, high-density, and large, bulky materials such as ore and gravel.

Combined discharge: This type of elevator combines the advantages of centrifugal and gravity discharge. The hopper operates at a moderate speed, discharging part of the material by centrifugal force and the remainder by gravity. This combined advantage of both discharge methods offers a wider range of applications. It is suitable for conveying highly viscous and easily agglomerated materials.

Classification by chain structure

Single chain: Single chain elevators utilize a single, endless chain to which the hopper is attached. They offer a simple structure and low cost. They are typically used for conveying small volumes and low heights. Double-chain type: A double-chain elevator uses two parallel, endless chains, with the hopper secured to each chain at each end. This type of elevator offers a large load capacity, smoother operation, and effectively prevents the hopper from tilting or swinging during conveying. It is suitable for applications with large conveying volumes, high conveying heights, or bulky materials.

What are the advantages of a chain bucket elevator?

Due to its unique structural design, the chain bucket elevator offers several advantages for vertical material conveying, making it an excellent choice over other conveying methods in many industrial applications.

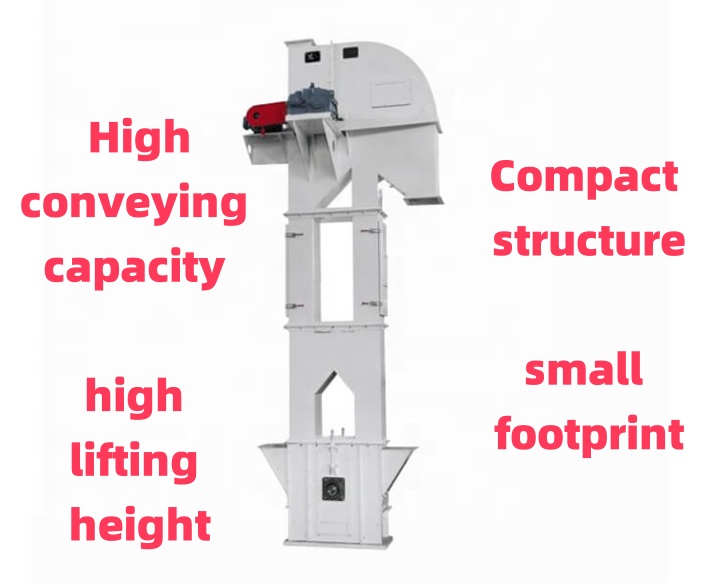

High conveying capacity and high lifting height: The chain bucket elevator can handle large volumes of material and reach high lifting heights. Its stable chain drive structure offers high load capacity, allowing it to carry larger material loads and is suitable for large-volume, long-distance vertical conveying of materials, such as in the cement and mining industries.

Compact structure and small footprint: Due to its vertical conveying system, the chain bucket elevator significantly reduces floor space compared to horizontal conveyors (such as belt conveyors). It can fully utilize the height space available in factories or workshops, making it particularly suitable for space-constrained production environments and helping to optimize factory layouts.

Wear-resistant and long service life: The main vulnerable parts of an elevator are the chain and hopper, which are typically made of high-strength, wear-resistant materials to withstand wear and impact from materials. The chain structure is stronger than a belt structure and less prone to tearing or damage, making it particularly durable when handling abrasive materials.

Stable operation and easy maintenance: The chain bucket elevator uses a sprocket meshing drive, ensuring smooth operation and preventing slippage. Its relatively simple structure also minimizes routine maintenance and overhaul. When the chain or hopper needs replacing, it's easy to do, helping to minimize downtime.

Chain bucket elevator parameters

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

What are the applications of chain bucket elevators?

The core application of a chain bucket elevator lies in its ability to stably and continuously transport granular or bulk materials vertically from a low to a high level. Its application scenarios are diverse, including vertical material conveying, which is a primary application of the chain bucket elevator. In various production lines, when materials need to be transferred from lower equipment (such as feeders or crushers) to higher equipment (such as storage silos or hoppers), elevators provide an efficient vertical solution. This method saves significant floor space and is ideal for space-constrained locations. For material transfer and loading, in material collection, transfer, and distribution systems, chain bucket elevators are used to transport materials from above or below ground level and then load them into hoppers, silos, or transport vehicles. This allows materials to be easily transferred to subsequent processing, storage, or transportation. For process connection, in complex production processes, elevators serve as a bridge connecting different process stages. They lift materials after initial processing to the entrance of the next process, ensuring the continuity and automation of the entire production line. In material storage and logistics, chain bucket elevators are used for both loading and unloading. They can lift bulk materials (such as coal, grain, or sand) from the ground to elevated silos or hoppers, or unload materials from elevated locations onto transport vehicles. This not only saves space but also simplifies material handling.

Chain Bucket Elevator Price

The price of a chain bucket elevator isn't fixed; it's influenced by a variety of factors, ranging from $300 to $7,000 or even higher. The key factors influencing price are:

Conveying capacity and lifting height: These are the primary factors influencing price. Conveying capacity (tons of material conveyed per hour) and lifting height directly determine the required power, chain strength, hopper size, and machine structure. Greater conveying capacity and higher lifting height require stronger and larger components, naturally increasing the cost.

Conveyor Belt Material: Conveyor belt prices vary significantly depending on the material. Ordinary steel chains are relatively inexpensive, while special alloy steel or stainless steel chains designed for use in specialized environments (such as high temperatures and corrosive environments) have higher manufacturing costs, increasing the price accordingly.

Construction Type and Configuration: Single-chain and double-chain elevators vary in cost. Double-chain elevators are generally more expensive than single-chain elevators due to their more stable load-bearing capacity. Additionally, additional features, such as the machine material, drive system, and safety systems, can affect price. Brand and Service: Well-known brands typically have higher R&D investments and better after-sales service guarantees, and their products are also relatively expensive. Therefore, when choosing a brand, consider not only the initial purchase cost but also the equipment's durability, operational stability, and ongoing maintenance costs.

In practical applications, chain bucket elevators provide a stable solution for vertical material conveying. Their chain drive structure adapts to the needs of various materials and resists material abrasion to a certain extent. Their vertical layout helps conserve floor space and accommodates layout constraints within factories or workshops. In daily production operations, chain bucket elevators enable continuous material transfer, providing essential support for subsequent processing, storage, or loading. Their operating status is strictly monitored, ensuring smooth material conveying.