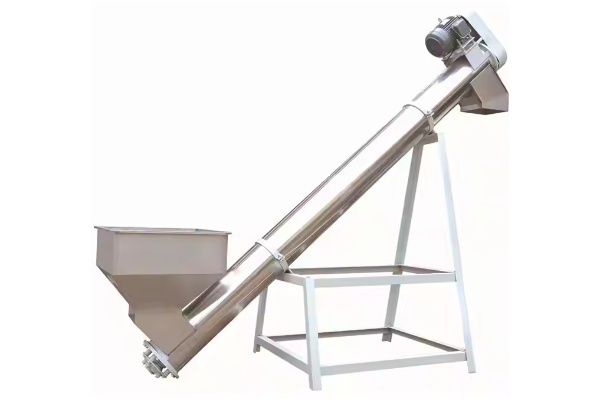

Vinyl Powder Screw Conveyor

The price of Vinyl Powder Screw Conveyor varies depending on its model, material, explosion-proof level, and customized design. Its price ranges from US$150 to US$8,000.

Rotation speed: 45-70 R/Min

Stainless steel: 201, 304, 316

Frame material: carbon steel/stainless steel

Power: 0.4kW-22kW

Voltage: 220V/380V/415V

Frequency: 50/60Hz

What is Vinyl Powder Screw Conveyor?

The Vinyl Powder Screw Conveyor is designed to handle various types of vinyl powder, ensuring smooth, contained conveyance from the silo to the production line. Vinyl powder is typically fine, lightweight, easily airborne, and potentially sticky. To address these material characteristics, the Vinyl Powder Screw Conveyor is typically constructed of stainless steel to meet the required purity. Depending on the conveying distance and process requirements, different screw structures can be selected. For example, a flexible screw conveyor uses a shaftless design to avoid material entanglement and clogging, making it particularly suitable for handling easily agglomerated powders. A tubular screw conveyor, with its fully enclosed tube, isolates the material, minimizing dust spillage and cross-contamination. In terms of processing capacity, a vinyl powder screw conveyor can handle powder volumes ranging from several to tens of cubic meters per hour. The conveying distance of a single unit typically ranges from a few meters to over 20 meters, depending on the screw diameter, rotational speed, and material density.

What are the types of Vinyl Powder Screw Conveyor?

Vinyl powder is a common bulk material that may have poor fluidity, easy bridging, easy adhesion, and even dust explosion risks under certain conditions during the conveying process. Therefore, when choosing a Vinyl Powder Screw Conveyor, these material characteristics need to be considered to determine the appropriate type. The types of screw conveyors are usually classified according to their casing form and spiral structure:

Classification by casing form

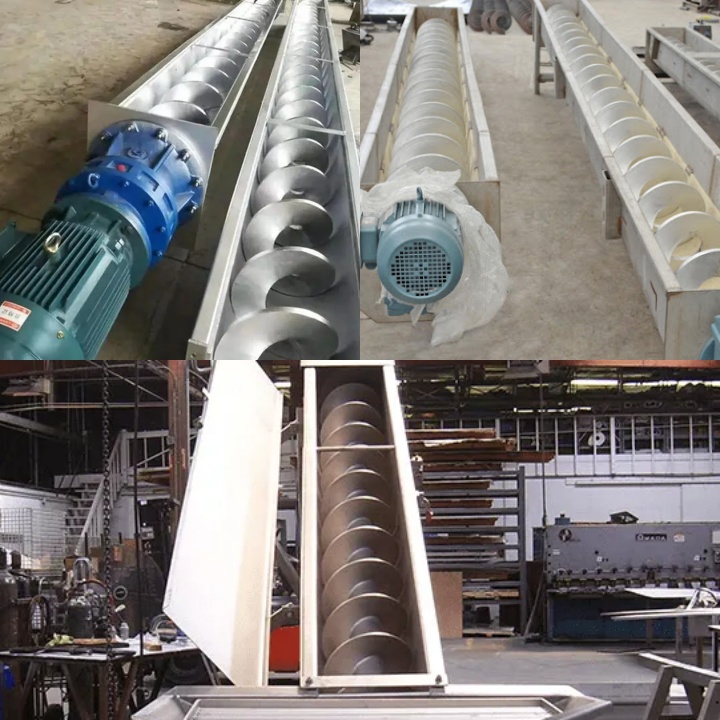

Tube screw conveyorThe spiral blades rotate in a fully enclosed circular tubular casing. This is a common and recommended type for conveying vinyl powder. It has very good airtightness, which can effectively prevent dust from spilling out and external pollutants from entering, and can provide better safety protection for vinyl powder with dust explosion risks. At the same time, the closed environment also prevents the material from getting wet, which helps to maintain the fluidity of the powder. The tubular design also supports inclined or even vertical conveying.

The spiral blades rotate in a U-shaped or O-shaped open trough body, usually covered by a cover. Compared with the tube type, the trough type has slightly worse sealing. Although it can be sealed with a tight cover, its dust and moisture resistance is slightly worse than the tube type. For vinyl powder, it can be considered if the environmental requirements are not high or the conveying distance is short, and the material fluidity is good. However, when it comes to potential dust explosion risks, its airtightness may not reach the safety level of the tube type.

Classification by spiral structure

Shafted screw conveyorThe spiral blades are welded on the central shaft, and the blades are driven by the rotation of the central shaft to convey the material. For vinyl powders with good fluidity and not easy to agglomerate or adhere, shafted screw conveyors can provide stable conveying. However, due to the existence of the central shaft, vinyl powder may adhere to or form bridges on the shaft, especially when the humidity is high or the powder has a certain viscosity, which may cause blockage. This needs to be evaluated based on the flow characteristics of the specific powder.

There is no central shaft, only a flexible spiral body rotating in a trough or special tubular shell. This is one of the ideal choices for conveying vinyl powder. The shaftless design greatly reduces the possibility of material adhesion or bridging on the central shaft, because there is no internal bearing obstruction, the conveying space is larger, and it is more suitable for conveying materials with strong viscosity, easy to entangle, easy to agglomerate or poor fluidity. This has significant advantages for materials such as vinyl powder that may have these characteristics, which can effectively prevent blockage and reduce the frequency of cleaning.

What are the advantages of Vinyl Powder Screw Conveyor?

The conveying of vinyl powder (such as PVC powder) has special requirements for equipment. Vinyl Powder Screw Conveyor has many advantages due to its design features, such as strong airtightness, convenient maintenance, flexible path, and space saving.

Strong airtightness: This is its significant advantage. Vinyl Powder Screw Conveyor usually adopts a fully enclosed tubular structure, which can effectively prevent dust from leaking and flying during the conveying process. This is especially important for vinyl powder that is prone to dust. It not only improves the cleanliness of the working environment, but also prevents dust from contaminating surrounding equipment or the environment. Airtightness also helps to prevent the material from getting wet and maintain good fluidity of the powder.

Excellent anti-blocking and anti-adhesion capabilities: Many vinyl powders have certain stickiness or easy agglomeration characteristics, which can easily cause blockage during the conveying process. Vinyl Powder Screw Conveyor usually uses a shaftless spiral design. The shaftless screw has no central axis to hinder it, so the conveying space is larger, which can effectively reduce the adhesion and bridging of materials inside, thereby ensuring smooth material conveying and reducing the frequency of shutdown for cleaning.

Conveying safety guarantee: Considering that vinyl powder may have the risk of dust explosion at a certain concentration, the fully enclosed tubular screw conveyor design can confine the dust in the tube and reduce the possibility of dust and air mixing to form an explosive mixture. In addition, for high-risk environments, it can also be equipped with explosion-proof motors and related electrical control systems to further improve the safety of the conveying process.

Flexible path and space saving: Vinyl Powder Screw Conveyor can realize horizontal, inclined or even vertical conveying according to site needs. This multi-directional conveying capability enables it to adapt to complex plant layouts and complete the height difference or long-distance conveying of materials within a limited floor space, thereby optimizing space utilization and reducing the need for multi-stage transfer equipment.

Parameters of Vinyl Powder Screw Conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the structures of Vinyl Powder Screw Conveyor?

The structure of Vinyl Powder Screw Conveyor is designed to meet its special requirements for airtightness, anti-clogging and safe operation. Although the specific structure will vary depending on whether it is tubular or trough type, with or without shaft, the core components and basic working principles are similar. Regardless of the type, Vinyl Powder Screw Conveyor usually consists of the following main parts:

Screw: This is the core working part of the conveyor. It is composed of spiral blades, which are wound around a central axis (with shaft) or form an independent spiral body by themselves (without shaft).

Casing: Tubular casing, for vinyl powder conveying, a circular fully enclosed tubular casing is common. This design provides excellent airtightness, which can effectively prevent dust from spilling out and external contaminants from entering, and is safer for vinyl powder with dust explosion risks. Trough casing, usually U-shaped or O-shaped open trough, the top is sealed by a cover plate. Although it also has a certain degree of sealing, it is usually not as thorough as the tubular type in terms of dust and moisture resistance.

Drive: Provides power for the rotation of the screw. It usually consists of a motor, a reducer and a coupling. The drive can be located at one end of the conveyor (head or tail) or in the middle when conveying over long distances.

Feed port: The port where the material enters the conveyor. Depending on the source of the material (such as a silo, a mixer, a ton bag unloading station), the feed port can be square, round, and may be equipped with a connecting flange or a flexible joint.

Discharge port: The port where the material is discharged from the conveyor. It can be located at the end of the conveyor or set somewhere in the middle as needed.

Bearing: Shaft type, including head and tail bearings (usually external bearings) and possible hanging bearings (used to support long-distance spiral shafts). Shaftless type, since there is no central shaft, usually only has bearings at the drive end and the tail end to support the spiral body, and the internal wear-resistant lining is used to support the operation of the spiral body.

In view of the structural characteristics of vinyl powder, the parts in contact with vinyl powder (spiral body, inner wall of the casing) are usually made of stainless steel (such as 304 or 316L) to ensure corrosion resistance, easy cleaning, and prevent material contamination. Especially at the shaft ends and various joints, high-standard seals (such as packing seals and mechanical seals) are used to ensure that dust does not leak out and moisture does not enter. In order to facilitate maintenance and cleaning, especially when different types of powders need to be replaced, some designs will consider quick-open inspection ports, removable end covers or pull-out screws to facilitate thorough cleaning of the interior. If vinyl powder poses a risk of dust explosion, the conveyor design will comply with relevant explosion-proof standards, including explosion-proof motors, anti-static conveying pipes, grounding devices, and possible explosion-proof pressure relief ports. In shaftless screw conveyors, the inside of the trough is usually lined with polymer wear-resistant materials to reduce friction and wear between the screw and the casing, while reducing noise. These structural considerations work together to ensure that the Vinyl Powder Screw Conveyor can complete material conveying tasks safely and stably.

What are the applications of Vinyl Powder Screw Conveyor?

Vinyl Powder Screw Conveyor plays a role in a variety of industrial production and processing links. Its main function is to transfer vinyl powder safely, closed and continuously. Its application scenarios include powder transmission and process connection. In the production process, it stably transports vinyl powder from storage containers (such as silos, silos, and ton bag unloading stations) to downstream processing equipment such as mixers, reactors, granulators or extruders to ensure the continuous operation of the production line. Accurate metering and feeding. By controlling the speed of the screw, the conveyor can achieve accurate and quantitative feeding of vinyl powder to meet the strict requirements of the formulation process for the amount of material added, such as in plastic modification or composite material production. Dust control and safety. Given that vinyl powder may generate dust and has potential flammable and explosive risks, this fully enclosed conveying method can effectively suppress dust diffusion and reduce safety hazards. Moisture and pollution prevention: The closed conveying environment can effectively isolate external moisture and impurities, protect the dryness and purity of vinyl powder, and avoid agglomeration due to moisture or pollution that affects product quality. Material recovery and recycling: In some scenarios where production waste or by-products need to be recycled, Vinyl Powder Screw Conveyor can be used to transport waste powder to recycling or reprocessing units.

Vinyl Powder Screw Conveyor Case

Vinyl powder is widely used in many industries. Screw conveyors are ideal for handling such powders due to their airtightness, conveying efficiency and adaptability. Vinyl Powder Screw Conveyor is usually used to convey powder from one production link to the next link, such as taking it out from a storage silo, hopper or big bag and then feeding it into a mixer, extruder, metering system or packaging line. In the plastics and polymer industry, screw conveyors are used to convey PVC resin powder for the production of PVC pipes, profiles, cables, flooring (such as SPC flooring), artificial leather, film, etc. The conveyor transports PVC powder from the raw material silo to the mixer or extruder. When producing plastic products, various powdered stabilizers, lubricants, plasticizers, pigments, etc. need to be added. Screw conveyors are used to accurately measure and convey these trace or small batches of powder. When producing some building composite materials, vinyl powder may be used as an adhesive or modifier. Screw conveyors are used here for precise batching and conveying. Vinyl powder may be used as a raw material or intermediate product for certain chemical reactions and needs to be conveyed and metered during the production process. Due to certain characteristics of vinyl powder (such as possible corrosiveness or sensitivity to humidity), the airtightness advantage of screw conveyors is particularly prominent. Some coatings and inks may contain vinyl powders in their formulations as rheology aids or to provide special properties. Screw conveyors can be used to precisely add these powders. In plastic recycling, crushed and ground vinyl (or other plastic) powders or granules also need to be transported, sorted or further processed by screw conveyors. By selecting the right screw conveyor type and configuration, the challenges of conveying vinyl powders in different industrial applications can be effectively solved.

Vinyl Powder Screw Conveyor plays an important role in the current powder processing process. Its advantages include providing a closed conveying environment, which helps to suppress dust diffusion and prevent materials from being damp or contaminated. At the same time, by optimizing the spiral structure, such as adopting a shaftless design, it can effectively deal with the adhesion and agglomeration tendency of vinyl powder and ensure smooth flow of materials. When selecting equipment, it is necessary to combine the specific physical properties of vinyl powder (such as fluidity, bulk density), the required conveying volume, the actual conveying distance and lifting height, and the specific requirements of the site for explosion-proof, hygiene and maintenance convenience.