Vertical Powder Packaging Machine price

Saturday January-31 2026 15:44:21

Vertical Powder Packaging Machine price from $5,000 to $20,000, depending on factors such as automation level, metering system type, packaging size, and packaging speed. They can package 10-3,000 grams of powdered material at a speed of 20-70 bags per minute. Because powdered materials have poor flowability and are prone to clogging, vertical packaging machines are used. These machines employ gravity feeding, resulting in a smoother structure and reducing problems such as material blockage, dust spillage, and difficult cleaning.

The Vertical Powder Packaging Machine is suitable for pillow bags, stand-up pouches, three-side seal bags, and four-side seal bags. Its metering accuracy is typically ±0.1% to 0.5%, allowing precise control of the powder content in each bag, thus enabling fast and accurate packaging of powder products into pouches or containers. This equipment is suitable for a variety of powders, including free-flowing powders, easily agglomerated powders, hygroscopic powders, and corrosive powders.

Impact of the price of accessories for vertical powder packaging machines

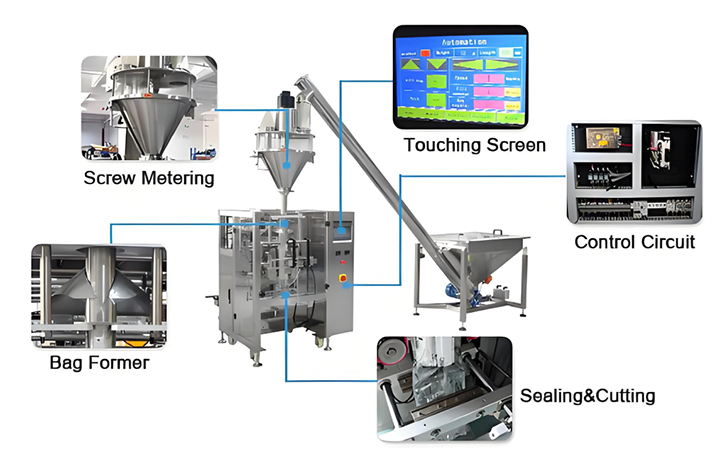

Factors affecting Vertical Powder Packaging Machine price include the metering and filling system, bag forming system, control system, and machine body materials. Differences in these components determine the equipment's performance, efficiency, durability, and degree of automation, thus affecting the price.

Metering and Feeding System: Conventional screw metering is suitable for standard powders with good flowability and stable density. High-precision servo-driven screws can memorize multiple material recipes, making material changeovers easier, but are more expensive. Measuring cup metering is suitable for granules or powders with excellent flowability and offers very high speed, but with lower accuracy compared to screws. The cost is generally between conventional and servo screws.

Forming and Sealing Mechanism: Using a servo drive or dual temperature control system for the sealing mechanism achieves higher sealing accuracy and speed, making it suitable for food- and pharmaceutical-grade powders. However, the cost is higher than traditional pneumatic sealing systems.

Control System: A PLC touch screen combined with an intelligent detection system improves operational convenience and stability. Imported control components, especially those from Siemens and Mitsubishi, can increase the overall machine price.

Materials and Frame Structure: 304 or 316L stainless steel is corrosion-resistant and meets food-grade requirements. The price is approximately 30% higher than carbon steel frames.

Additional Features: Adding dust removal, vacuum loading, automatic printing, and nitrogen filling will further increase the overall price.

Vertical Powder Packaging Machine Parameters

|

Machine Model

|

LD-620AS

|

LD-720AS

|

LD-900AS

|

|

Pouch size

|

W: 130-300mm L: 100-500mm

|

W: 130-350mm L: 100-600mm

|

W: 130-380mm L: 100-900mm

|

| Making-bag volume | 3000ml | 5000ml | 7000ml |

|

Filling range

|

200g-2kg

|

500g-3kg

|

1kg-5kg

|

| Power Supply | 220V,50/60Hz,3KW | 220V,50/60Hz,3KW | 220V,50/60Hz,3KW |

|

Packing speed

|

10-90 bag/min According to the product character

|

||

|

Power

|

1.5-4.5KW AC220V/380V±10% 3-PHASE 50HZ/60HZ

|

||

| Film material | BOPP/CPP,BOPP/VMCPP,BOPP/PE,PET/VMPET/PE,PET/AL/PE,PET/PET/ETC. | ||

Vertical Powder Packaging Machine Working

Powdered materials are precisely metered under PLC control and fall through a filling tube into packaging bags automatically produced by a vertical powder packaging machine. The vertical powder packaging machine unfolds the film through a film feeding system, completes bag making and shaping after photoelectric correction, and completes longitudinal and transverse sealing by a heat sealing device after powder filling, and finally cuts it into single-bag finished products.

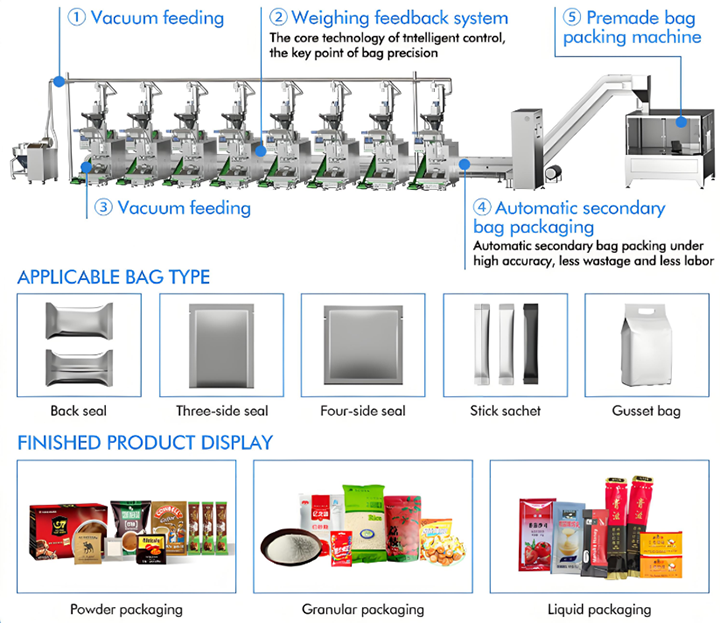

What bag types does the Vertical Powder Packaging Machine support?

When considering the Vertical Powder Packaging Machine price, you also need to consider the price of packaging bags. Generally speaking, four-side seal bags and stand-up bags are relatively expensive, while three-side seal bags and back seal bags have relatively simple structures and are cheaper.

The Vertical Powder Packaging Machine is compatible with a variety of bag types: Three-side seal bags, with seals on the sides and bottom and an open top, offer a strong seal and are suitable for moisture-absorbing powders such as coffee powder and milk powder. Four-side seal bags are fully sealed on all sides and offer enhanced leak-proofing, making them ideal for pharmaceutical powders and additive powders to minimize spillage. Back-seal bags have a seal on the back, leaving a flat front for easy printing, making them suitable for bulk powders such as flour and meal replacement powders. Stand-up bags have a support base for self-standing, making them easy to access and commonly used for protein powders and seasoning powders. Gusset bags, with gusseted sides, offer a three-dimensional feel and excellent load-bearing capacity, making them suitable for bulk powders such as industrial talc and building plaster.

Vertical Powder Packaging Machine Supplier

When purchasing a vertical powder packaging machine, choose us, a factory with over 15 years of experience manufacturing and developing this type of equipment. As a leading manufacturer of packaging machines, we can customize machines to meet a wide range of powder characteristics, including laundry detergent and powdered sugar, and to meet a wide range of requirements, including custom packaging capacities up to 10kg. We offer trial runs with materials and online customization services with our professional engineers.

What is the difference between Vertical Powder Packaging Machine price and horizontal packaging machine?

When choosing a powder packaging machine, there are two different types of vertical powder packaging machines. Vertical machines have higher vertical space utilization and a smaller footprint, while horizontal machines are more suitable for pre-made bags. Below is a comparison of the two types of machines. Please choose the machine that best suits your needs.

Vertical powder packaging machines cost approximately $4,000–$10,000. After forming the bag, the bag is filled from above, reducing dust. Vertical form-fill-seal machines are often equipped with weighing, metering, vibration, vacuum/nitrogen filling, coding, and pneumatic sealing, enabling precise control of powder quantities. Vertical machines are compact and typically pack at speeds of 20–120 bags per minute. Used vertical or form-fill-seal machines can be sold at 30%–70% lower prices.

Horizontal packaging machines are more suitable for existing bags or stick-shaped packets (such as powder packets and sticks). Horizontal packaging machines are particularly efficient for pillow-seal or three-side-seal applications. Horizontal powder packaging machines have a capacity of 30–180 bags/minute. Horizontal bagging machines cost approximately $6,000–$15,000. Horizontal bagging machines are specialized for pre-made bags, pillow bags, and stick-shaped packaging, and can perform functions such as bag feeding, alignment, filling, back/three-side sealing, counting, and labeling.

Tip: Selection should be based on material characteristics and bag type. Vertical packaging machines are preferred for powders prone to flying or for applications requiring high precision. Horizontal packaging machines are recommended for applications requiring high speed, stick-shaped packaging, or pre-made bags. Used form-fill-seal machines and vertical packaging machines for sale can save costs. However, the electrical, air, sealing, and metering systems should be inspected to ensure stable operation.

Vertical Powder Packaging Machine production line display

When selecting a Vertical Powder Packaging Machine, the metering equipment must be adjusted accordingly for powder materials with different properties. Free-flowing materials like milk powder can use a standard screw; flours that easily absorb moisture or adhere require an anti-stick screw and heated moisture-proof devices; dust-prone talcum powders should be equipped with a negative pressure dust removal system; ultrafine powders like titanium dioxide require a high-precision micro-metering mechanism to prevent clogging; high-density metal powders require a reinforced load-bearing structure and wear-resistant materials; and corrosive chemical raw materials require 316L stainless steel contact parts.Vertical Powder Packaging Machine prices vary depending on the machine components, bag type, and manufacturer. Contact us online for the best solution.