Suction Machine

The price of a suction machine varies greatly depending on its type, and the materials and configuration used, ranging from US$200 to US$3,000 or even higher.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 2T/h - 25 T/h

Length: 3 to 30 meters

Width or diameter: 100mm

Material: Stainless steel/Carbon steel

What is Suction Machine?

Suction Machine use pneumatic conveying to transport powders, granules, flakes, or crushed materials. Depending on their structure and movement method, suction machines are primarily categorized into three types: mobile, fixed, and handheld, adapting to different production environments. In practice, suction machine throughput typically ranges from tens of kilograms to several tons per hour, with single-pass conveying distances ranging from a few meters to tens of meters.

What are the types of suction machines?

Suction machines are essential equipment in the material conveying industry, utilizing pneumatic conveying principles to automate material handling. Based on their structural features and application methods, suction machines are primarily classified into three categories: mobile, fixed, and handheld. Each type has its own unique characteristics, adapting to different production environments and conveying requirements, offering advantages in efficiency, flexibility, and application range.

Mobile Suction Machine

Structural Features: A mobile suction machine typically consists of one or more suction units, a storage hopper, a power system (such as a vacuum pump or fan), and a filtration and control system. Its main feature is casters or wheels, allowing for easy movement between workstations and multi-point material collection. Some mobile suction machines are also equipped with hoses or telescopic tubes to accommodate varying suction distances and heights. They are relatively compact, occupy a small footprint, and offer high flexibility.

Applicable Materials: This type of suction machine is suitable for applications requiring frequent workstation changes or for conveying materials between multiple workstations. It is commonly used to collect plastic pellets, powders, flakes, crushed materials, and some lightweight, non-abrasive particles. Its high mobility makes it particularly well-suited for production environments such as injection molding plants, extrusion lines, and packaging plants, where materials must be drawn from multiple bins or bags.

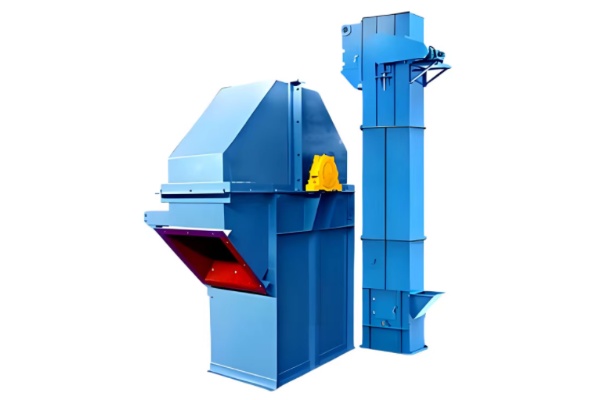

Fixed Suction Machine

Structural Features: A fixed suction machine is typically installed in a fixed location, such as above a silo, next to a production line, or in the main room of a central feed system. It is larger and more powerful. It is typically connected to a piping system, using a fixed suction port or distributor network to centrally transport materials from multiple remote feed points to one or more processing equipment. This type of design aims to achieve automated, continuous material conveying, typically requiring engineering design and piping layout.

Applicable Materials: Stationary suction machines, with their powerful conveying capacity and continuous operation, are suitable for production scenarios requiring large-scale, long-distance, and high-intensity material conveying. They can handle a variety of materials, including plastic granules, powders, pellets, and fibers. In industries such as plastics processing, chemicals, and grain, stationary suction machines are essential components of central feeding systems or large-scale production lines, automatically feeding materials from large storage tanks or silos to multiple processing equipment.

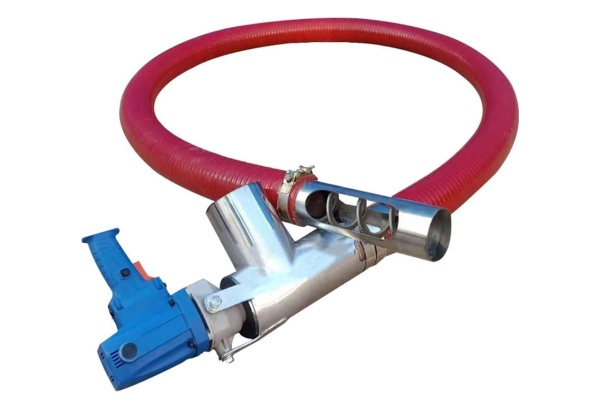

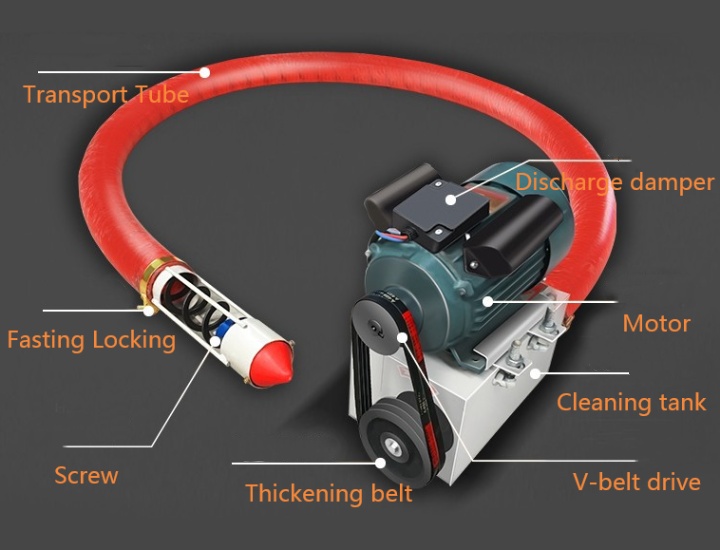

Handheld Suction Machine

Structural Features: As the name suggests, a handheld suction machine is a small, lightweight suction device that can be handheld by an operator. It typically consists of a small motor, a suction nozzle, a filter bag or dust collection bucket, and a handle. Its simple structure and flexible operation make it primarily suitable for small-batch, point-to-point, or hard-to-reach material collection or conveying.

Applicable Materials: This type of suction machine is primarily used for small-scale material cleaning, recycling, or small-volume replenishment. It is suitable for suctioning materials such as fine particles, powders, and debris. For example, they can be used to clean up fallen particles at the end of a production line, vacuum residual materials in confined spaces, or dispense and transfer small quantities of materials in laboratories. Due to their limited conveying capacity, they are not suitable for large-scale, high-intensity material handling tasks.

What are the advantages of suction machines?

Suction machines, as a type of material handling equipment, play a vital role in industrial production. Through automated, closed-loop conveying, they ensure safe and clean material handling while effectively reducing manual intervention and material loss. Their advantages are primarily reflected in the following aspects:

Automation and Efficiency: Suction machines automate material handling, eliminating the arduous manual labor of manual handling. They automatically extract materials from silos, bags, or drums and deliver them to designated locations, such as injection molding machines, extruders, or mixers, significantly improving production efficiency. This automated process reduces reliance on manual labor and minimizes the potential for errors caused by manual operation.

Safety: Because suction machines utilize a closed system, material is conveyed within a pipe, effectively preventing hazards to operators during the material handling process, especially for toxic, hazardous, or flammable or explosive materials. Automated conveying also reduces the risk of workplace injuries associated with manual handling, improving production safety.

Space Saving and Flexibility: Suction machines convey materials through pipes that can be flexibly placed on the ceiling, walls, or corners of the workshop, eliminating valuable floor space. This is a significant advantage for factories with limited space. Furthermore, mobile suction machines can be easily moved between production lines, enabling multi-point material feeding and providing significant flexibility.

Reduced Material Loss: Suction machines utilize vacuum or pneumatic conveying principles, minimizing friction and collision between materials and the pipe's inner wall during conveying. This helps minimize material breakage and loss, especially for granular materials. Furthermore, the closed conveying system prevents material waste caused by spillage or leakage.

Suction Machine Parameters

| Pipe diameter | Length | Voltage | Power | Efficient | Weight |

| 100mm | 3m | 220V | 3KW | 5-6t/h | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6t/h | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6t/h | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6t/h | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6t/h | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6t/h | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6t/h | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6t/h | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6t/h | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6t/h | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8t/h | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8t/h | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8t/h | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8t/h | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8t/h | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8t/h | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8t/h | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8t/h | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8t/h | 89kg |

| 120mm | 12m | 380V | 4KW | 7-8t/h | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6t/h | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6t/h | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7t/h | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7t/h | 200kg |

How does a suction machine work?

A suction machine utilizes the principles of pneumatic conveying, creating negative pressure (vacuum) to draw in and convey materials. Simply put, it's like a powerful vacuum cleaner, but for granular or powdered materials. The operation of a suction machine is generally divided into four main stages. In the suction stage, the core of the suction machine is a vacuum pump or fan. When the vacuum pump is activated, it extracts air from the suction machine's hopper or barrel, creating a negative pressure environment inside. A suction gun or nozzle is connected to the other end of the pipe, and the negative pressure is transmitted through the pipe to the nozzle. When the nozzle contacts the material, the pressure difference between the inside and outside is caused to pull the material and the surrounding air into the pipe. In the conveying stage, the sucked material moves at high speed within the pipe with the airflow. The force of the airflow "blows" the material toward the storage hopper. This process can quickly transport materials from one location to another, achieving point-to-point delivery. In the separation and filtration stage, once the material and airflow reach the storage hopper, they need to be separated. The storage hopper is usually equipped with a filter (such as a filter screen, filter element, or filter bag). After material enters the hopper, gravity causes it to settle to the bottom due to the increased pipe diameter and slower airflow. The airflow carrying the material then passes through filters, removing dust and other impurities, ultimately releasing clean air. During the discharge phase, when the material in the hopper reaches a set volume or after a set time, the suction machine stops sucking material. At this point, a discharge valve or pneumatic flap at the bottom of the hopper opens, automatically or manually unloading the material into the next piece of equipment, such as an injection molding machine, mixer, or packaging machine. After discharge, the system enters the suction phase again, beginning the next cycle.

What are the applications of suction machines?

Suction machines are a versatile material conveying device that can continuously and cleanly transport a variety of granular, powdered, and crushed materials. Their applications can generally be categorized based on material type, conveying distance, and production scale. Specifically, they fall into the following areas:

Automated material conveying and replenishment: The core application of suction machines is automated material handling on various production lines. It can automatically extract materials from large silos, bags, or drums and deliver them directly to production equipment, such as plastic pellets to an injection molding machine or extruder. This not only significantly improves production efficiency but also reduces the tediousness and potential errors of manual operations.

Material Recovery During Production: Some production processes may generate scrap, off-cuts, or substandard products. Suction machines can be used to quickly and efficiently recover these materials. For example, in the production of plastic products, crushed scrap can be sucked up and returned to the production line for reuse, thus reducing material waste.

Centralizing Dispersed Materials: In some environments, materials may be dispersed across multiple locations. Suction machines, particularly mobile ones, can flexibly move between these locations, sucking up and collecting dispersed materials into designated storage containers for subsequent centralized processing or reuse.

Maintenance and Cleaning: Suction machines can also serve as cleaning tools, removing residual materials, dust, and debris from production equipment, pipes, or floors. This application helps maintain a clean work environment and prevents cross-contamination between different materials. Material Handling in Special Environments: For materials with high environmental requirements or special properties (such as volatile, toxic, or materials requiring stringent cleanliness requirements), the closed conveying system used by suction machines effectively prevents contact between the material and the outside environment, ensuring safety and cleanliness during the conveying process.

Suction machines, as a material conveying tool, are widely used in the industrial sector. When selecting and using a suction machine, it is important to consider the material properties, required handling volume, and conveying distance based on actual needs. Different types of suction machines have different structural and performance characteristics, which determine their application scenarios. For example, mobile suction machines are suitable for multi-point operations, fixed suction machines are suitable for centralized feeding systems, and handheld suction machines are primarily used for small-scale material cleaning and replenishment. By selecting the appropriate equipment type and configuration, you can ensure smooth and stable material conveying, thereby meeting the specific requirements of your production process.