Semi-automatic granule packaging machine price

Wednesday December-03 2025 15:17:00

Semi-automatic granule packaging machine price from $1,500 to $7,000, with price variations depending on machine configuration, control system type, and materials. Lower-end models typically feature basic volumetric cup filling machines, while higher-end models integrate advanced weighing systems and more complex control systems. Production capacity is around 15 to 45 bags per minute, suitable for small to medium-sized production, startups, or dedicated packaging lines. Features include precise weighing/filling, manual or assisted bag opening, and a basic sealing mechanism (usually included). Handles both pre-made bags and roll-made bags. Packaging range is generally 10g–5kg, suitable for granular materials such as grains, spice granules, and plastic granules.

Different Types of Semi-Automatic Granule Packaging Machine Prices

Semi-automatic granule packaging machines can be categorized based on the bag loading method into pre-made bag semi-automatic granule packaging machines and roll-made bag semi-automatic packaging machines. Pre-made bag packaging requires manual assistance in bagging, while bag-making machines can automate the bag-making process.

Pre-made bag semi-automatic granule packaging machine: This type of machine requires the operator to manually attach the pre-made bags to the filling nozzle. It is suitable for environments with low production volume and a wide variety of products, or for packaging fragile, irregular granules that require visual inspection. As long as the bag opening can be attached to the filling nozzle, the bag type is virtually unlimited; flat-bottom bags, zippered stand-up pouches, and bags with pleats on the sides are all suitable. Packaging capacity ranges from 50 grams to 25 kilograms. Speed depends on the operator, averaging 8-20 bags per minute. The function includes net weight measurement via a balance or load cell integrated into the filling head, and sometimes also includes a bag clamping device. Pre-made bag semi-automatic granule packaging machine price typically ranges from $1,500 to $4,000.

Semi-automatic granule packaging machine (bag-fill-seal type): This type of machine uses a roll of flat film to automatically complete the bag-making process. The operator is typically responsible for starting the cycle and monitoring operation. It is characterized by high efficiency and low unit bag material cost. They produce neat, professional pillow bags or gusseted bags with consistent sealing. Standard models typically have packaging capacities between 100 grams and 2 kilograms. Speeds are faster than pre-made bag machines, ranging from 20 to 45 bags per minute. Functions include film unwinding, bag making, precise volumetric or screw filling, and integrated heat sealing. Due to their higher mechanical complexity, they are more expensive, typically ranging from $4,000 to $7,000.

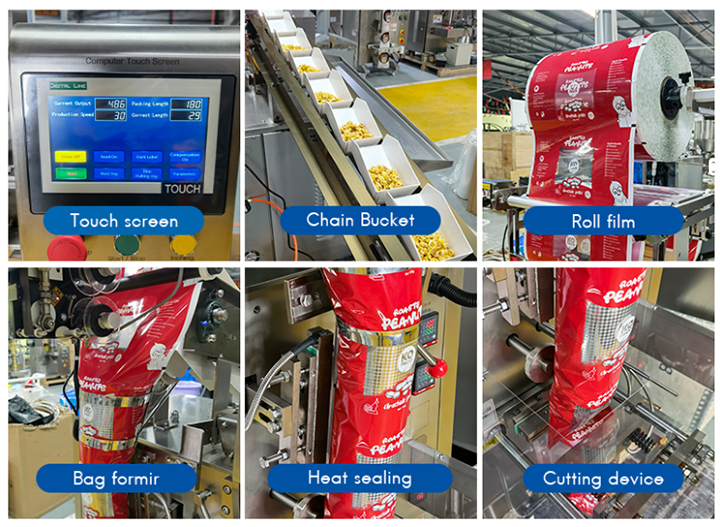

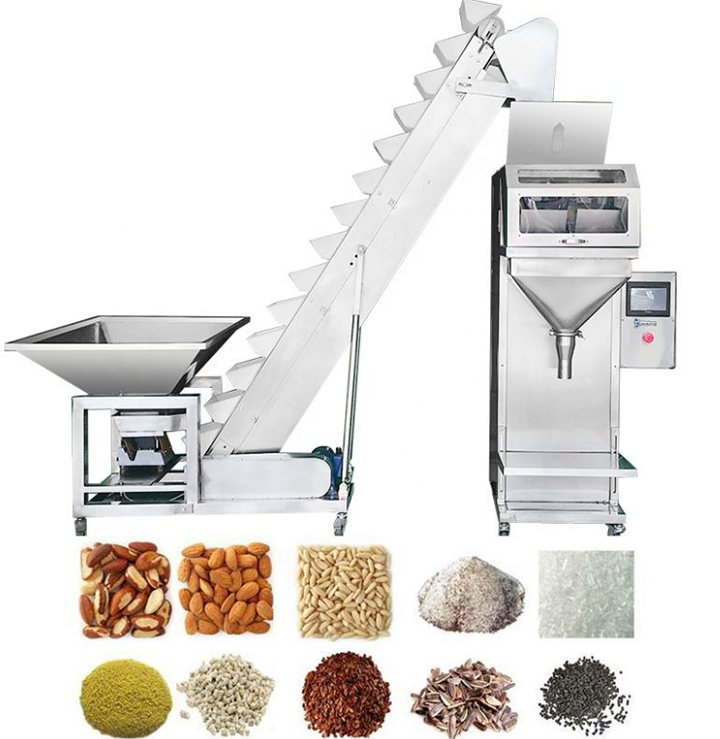

Semi-automatic granule packaging machine structure

The weighing system of a semi-automatic granule packaging machine includes a high-precision electronic scale, a measuring cup, and a screw feeder or vibratory feeder to output granular material at a set weight. The control system typically uses a PLC or intelligent microcomputer, allowing users to set parameters such as weight, counting, and feeding speed via a touchscreen, and monitor the operating status in real time. The storage hopper and feeding mechanism temporarily store materials and ensure uniform and continuous feeding, preventing blockages or deviations. Bag clamps and bag mouth supports automatically clamp the bag mouth, ensuring smooth granule filling. Conveyor belts or support platforms assist in the manual or automatic transport of finished bags. The sealing system, depending on the model, can be an external heat sealer or a built-in bag-making and sealing device. Semi-automatic granule packaging machine price is related to its structure; adding components such as dust collectors, air extraction systems, printers, and metal detectors will increase the price.

Factors Affecting the Semi-automatic granule packaging machine price

The following factors affect the price of a semi-automatic granule packaging machine. When purchasing equipment, you can choose suitable equipment and its additional devices based on your production capacity and budget.

Filling Technology: Basic volumetric filling machines are the most economical. Screw filling machines with servo motors for higher precision are more expensive. Integrated electronic weighing systems are the most expensive.

Construction and Materials: Machines made of stainless steel, suitable for food or pharmaceutical applications, are more expensive than those with low-carbon steel or painted frames used in industrial applications.

Level of Automation: Models with automatic bag feeding, automatic tare, batch counters, or printing functions are more expensive.

Bag Compatibility: Machines compatible with multiple bag types or with automatic bag opening devices are more expensive than those supporting only a single bag type.

Semi-automatic granule packaging machine price suppliers

There are many established companies worldwide specializing in mid-range packaging machinery, offering a good balance of price, performance, and localized technical services, making them a popular choice. Numerous factories in Singapore, China, and India produce machines of various specifications. Machrise manufacturers offer customization and highly competitive semi-automatic granule packaging machine price, and support services such as consultation, trial runs with materials, and after-sales support.

Semi-automatic granule packaging machines can package various types of granules, including sugar, salt, rice, lentils, coffee beans, seeds, spices, instant beverage powder, grains, frozen berries, fertilizers, animal feed, potting soil, plastic resins, detergent powder, industrial salt, traditional Chinese medicine granules, pills, screws, and nails. The choice between a flexible pre-made bag machine and a fast bag-making-filling-sealing machine depends on production volume requirements, bag type requirements, and budget. Understanding the machine's structure, the factors influencing semi-automatic granule packaging machine price, and suppliers will help in making informed purchasing decisions.