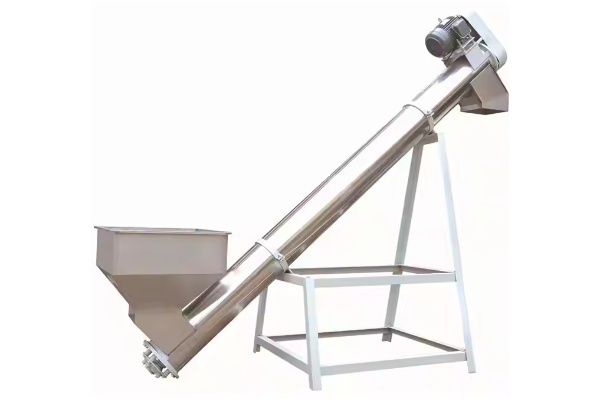

Sludge Shaftless Screw Conveyor

The price of Sludge Shaftless Screw Conveyor varies depending on factors such as model, material, length, processing capacity, and usually ranges from US$400 to US$6,500.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

What is Sludge Shaftless Screw Conveyor?

Sludge Shaftless Screw Conveyor is a kind of equipment used for material transfer. Its main function is to transport various types of sludge, grating residue and other bulk materials with stickiness or entanglement under specific working conditions. In actual application, its material handling capacity varies depending on the equipment model, material characteristics and operating conditions, and can usually meet the conventional transportation needs of municipal sewage treatment plants and industrial waste treatment facilities. In terms of conveying distance, this type of equipment can cover an area ranging from several meters to tens of meters, and is suitable for connecting the material path from the discharge port of the dewatering equipment to the subsequent stacking or transfer site.

What are the advantages of Sludge Shaftless Screw Conveyor?

Sludge Shaftless Screw Conveyor has significant advantages in the field of sludge treatment, especially for materials that are difficult to handle with traditional shaft screw conveyors. These advantages are mainly reflected in the following aspects:

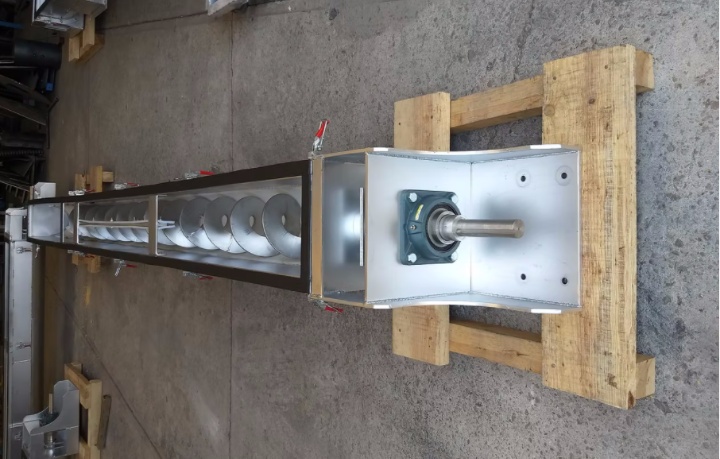

Suitable for sticky and entangled materials: Sludge usually has high humidity, high viscosity and may contain fibrous or entangled impurities. Traditional shafted screw conveyors are prone to material entanglement on the shaft or adhesion between the blades and the shaft due to the presence of a central shaft, causing blockage and shutdown. The shaftless screw conveyor has no central shaft, and its unique flexible spiral blade structure can effectively avoid these problems, making it perform superiorly when conveying sticky sludge, filter cake, screen residue and other materials.

Reduced blockage and cleaning frequency: Since there is no restraint of the intermediate bearing and the central shaft, the material is not easy to accumulate and block during the conveying process. This greatly reduces the failure rate and downtime of the equipment, reduces the frequency and difficulty of manual cleaning, and thus improves the operating efficiency and reliability of the system.

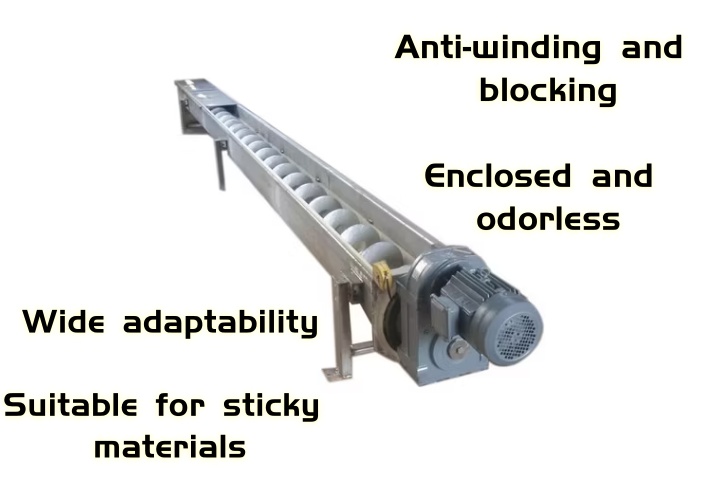

Fully enclosed conveying: Sludge conveying may produce odor or cause environmental pollution. Shaftless screw conveyors usually adopt a fully enclosed U-shaped groove design, which can effectively prevent odor from overflowing and material spilling, and keep the on-site environment clean and hygienic. This is especially important for sewage treatment plants or places with high environmental requirements.

Simple structure and easy maintenance: The shaftless screw conveyor has a relatively simple structure and no wearing parts such as intermediate hanging bearings. This reduces the workload of daily maintenance. When maintenance is required, it is also relatively easy to clean and inspect the interior due to its open U-shaped trough structure (after the inspection cover is opened).

Strong adaptability and flexible layout: The shaftless screw conveyor can achieve horizontal, inclined (usually up to 30° or even higher) conveying, and even vertical conveying under certain special designs. This flexibility enables it to adapt to complex on-site space layout requirements and meet the material conveying needs of different process flows.

Low wear and smooth operation: The spiral blades of the shaftless screw conveyor are usually thicker, and the friction between the spiral blades and the trough body occurs on the liner, which effectively reduces the wear of the spiral blades themselves. In addition, due to the low speed operation, it has lower noise and smoother operation.

Parameters of Sludge Shaftless Screw Conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the applications of Sludge Shaftless Screw Conveyor?

Due to its unique design and advantages, the Sludge Shaftless Screw Conveyor is widely used in a variety of scenarios for handling viscous, entangled or semi-fluid materials. Its main function is to achieve continuous and closed conveying of materials without the need for a traditional center shaft. In the field of industrial wastewater treatment, shaftless screw conveyors are commonly used to transport dewatered sludge in sewage treatment plants. This type of sludge is usually high in moisture, highly viscous, and may contain fibrous materials. Conventional shafted conveyors are prone to clogging, while shaftless designs can effectively solve this problem. In addition, they are also commonly used to transport grid residues, which are large, irregularly shaped, and easily entangled solid waste separated from sewage. In solid waste treatment, shaftless screw conveyors can be used to transport separated solid-liquid mixtures, kitchen waste, and waste slurries during leachate treatment or food waste treatment. In some incineration plants, they may also be used to transport materials such as slag or fly ash that are somewhat viscous and abrasive. For agricultural and food processing waste treatment, especially after the solid-liquid separation of livestock and poultry manure, shaftless screw conveyors can effectively transport the separated manure residue to the composting area or further treatment area. In food processing plants, shaftless screw conveyors provide a clean and hygienic conveying solution for by-products such as fruit residues, vegetable residues, and wine waste that have high moisture content and are prone to agglomeration or entanglement. The core application of Sludge Shaftless Screw Conveyor lies in its ability to reliably handle materials that are difficult for traditional screw conveyors to handle. Its closed, anti-clogging, low-maintenance and environmentally friendly characteristics make it an ideal choice for handling various types of viscous, entangled or semi-fluid wastes and by-products, playing a key material transfer role in multiple industries.

Sludge Shaftless Screw Conveyor Manufacturers

Sludge Shaftless Screw Conveyor manufacturers have demonstrated significant customization capabilities in meeting the diverse needs of customers. Due to the differences in sludge characteristics, processing volume, on-site space and process flow, standardized products are often difficult to fully adapt to all working conditions. Therefore, manufacturers usually have the ability to design and adjust conveyors in a targeted manner according to specific project requirements. Manufacturers' customization is mainly reflected in the following aspects. The first is the flexible adjustment of structural dimensions. This includes the conveying pipe diameter, conveying length, and the form and position of the inlet and outlet. For example, in the face of different mud outlet sizes of dewatering equipment (such as plate and frame filter presses or centrifuges), manufacturers can adjust the connection method and size of the feed inlet to ensure seamless docking. For narrow or special-shaped installation spaces, the overall layout and support structure of the conveyor can also be modified accordingly. The second is the customization of materials and wear-resistant design. The corrosiveness and abrasiveness of sludge vary greatly, and some sludge may contain highly abrasive particles or corrosive media. For such cases, manufacturers can provide a variety of material options, such as different grades of stainless steel (SS304, SS316L), wear-resistant steel, or the addition of polymer liners in key wear parts to extend the service life of the equipment and reduce the frequency of maintenance.

The third is the matching adjustment of the conveying capacity. This involves the pitch and thickness of the spiral blades and the selection of the drive system. By adjusting these parameters, the manufacturer can ensure that the conveyor reaches the required processing volume at a specific inclination angle. For example, for systems with large fluctuations in processing volume, variable frequency speed control motors can be configured to adapt to different flow requirements. In addition, manufacturers can also provide customization of auxiliary functions and automation levels. For example, adding a cleaning device to prevent the accumulation of sticky materials, setting multiple inlets and outlets to adapt to complex process flows, or integrating automation components such as liquid level sensors and blockage alarms to improve the operating reliability and management convenience of the equipment. Finally, customization is equally important in terms of installation methods and environmental adaptability. Whether it is overhead installation, ground installation or pit installation, the manufacturer can provide corresponding bracket design and anti-corrosion treatment solutions to ensure that the equipment can operate stably in harsh environments such as sewage treatment plants and garbage treatment plants. This comprehensive customized service enables Sludge Shaftless Screw Conveyor to be more accurately integrated into various complex sludge treatment systems.