Industrial Screw Conveyor Price

Thursday November-06 2025 10:40:07

The market price of an Industrial Screw Conveyor varies widely, ranging from $300 to $6,000, depending on the type of equipment, technical specifications, and manufacturing process. Industrial Screw Conveyor Price is primarily influenced by a combination of factors, including whether the conveyor is U-trough or tubular, whether it is made of carbon steel or stainless steel, and specific parameters such as the required conveying length and screw diameter. Furthermore, the brand and model of core components such as the motor and reducer will directly affect the final quote.

What types of industrial screw conveyors are there?

Industrial screw conveyors can be primarily categorized into three types based on their conveying direction: horizontal, inclined, and vertical. Each type has its own unique design features and application scenarios, and industrial screw conveyor price varies depending on structural complexity and performance requirements.

Horizontal Screw Conveyor

Features: High efficiency. During horizontal conveying, materials are less affected by gravity, resulting in high conveying efficiency and fill factor, enabling large conveying volumes. Its simple structure, typically employing a U-shaped trough or round tube design, is compact and easy to install and maintain. It has a wide range of applications, suitable for short-distance horizontal conveying of various powdered, granular, and bulk materials, and is a common method in industrial production lines.

Price: US$ 800–2,000. Due to its simple structure and mature manufacturing process, horizontal screw conveyors are generally the least expensive of the three types. Price is primarily influenced by factors such as conveying length, screw diameter, material (e.g., carbon steel, stainless steel), and drive system configuration.

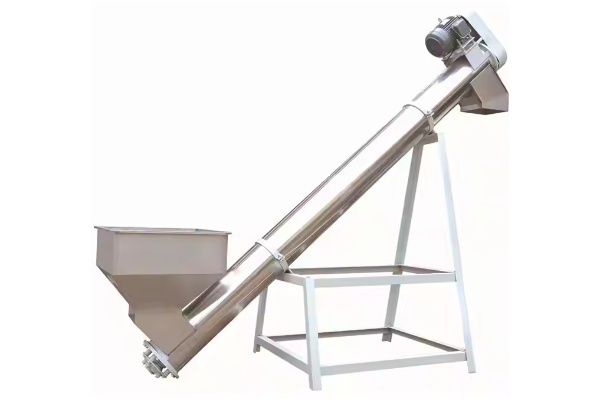

Inclined Screw Conveyor

Features: Space-efficient, capable of lifting materials within limited space, combining horizontal conveying and vertical lifting capabilities. As the inclination angle increases, the downward force of the material increases, resulting in a gradual decrease in conveying capacity and fill factor. The flexible application allows for adjustment of the inclination angle to suit the site layout, making it widely used in applications requiring spans or connecting different floors.

Price:US$ 500–4,000. Inclined screw conveyors are generally priced between horizontal and vertical types. The inclination angle, conveying height, and screw diameter are key factors in determining price. A larger angle increases the weight required to overcome, requiring higher motor power and structural strength, which in turn increases the price.

Vertical Screw Conveyor

Features: It occupies a small footprint and can achieve near-vertical material lifting, saving valuable floor space. Its conveying capacity is low. Because the material is almost entirely driven upward by the screw's thrust against gravity, its fill factor and conveying capacity are the lowest of the three types. A higher speed is generally required to generate sufficient centrifugal force to ensure stable material conveying. It is suitable for applications with limited space and low conveying volumes.

Price:US$ 700–5,000.Vertical screw conveyors are more complex to design and manufacture, placing higher demands on the drive system, balance, and safety, and are therefore generally more expensive of the three types. The conveying height is the main factor that determines its price. The higher the height, the higher the requirements for motor power and overall structural strength, and the higher the price.

What are the factors that affect Industrial Screw Conveyor Price?

Many factors influence Industrial Screw Conveyor Price, primarily including equipment type, structure, material, technical specifications, drive configuration, and degree of customization. These factors can be considered from the following perspectives:

Equipment Type and Structure

Conveying Direction: Screw conveyors are classified as horizontal, inclined, and vertical. Generally speaking, horizontal types have a simpler structure and are less expensive. Inclined types require overcoming gravity, requiring higher structural and power requirements, and are more expensive. Vertical types have a complex design and place higher demands on the motor, structural strength, and balance, resulting in a higher price.

Spiral Type: Spiral blades come in various forms, including solid, belt, vane, and shaftless. Shaftless screw conveyors are suitable for conveying highly viscous and easily entangled materials, but their structure and manufacturing process are more complex, resulting in a higher price than conventional shafted screw conveyors.

Material and Surface Treatment

Material Selection: The material used in a screw conveyor is a key factor influencing its price. Carbon steel is a common, low-cost material suitable for conveying general materials. For materials with corrosive or food-grade requirements, stainless steel must be used.

Wear-Resistant Treatment: When conveying highly abrasive materials, special treatment of the spiral blades is required to extend equipment life, such as welding a wear-resistant layer or using wear-resistant alloy steel.

Technical Parameters and Configurations

Conveying Length and Height: The longer the conveying length or the higher the vertical conveying height, the more components required, such as the spiral shaft, casing, and bracket, and the higher the manufacturing and installation costs.

Spiral Diameter and Pitch: A larger spiral diameter increases conveying capacity, but also requires more material, which increases the price. Pitch design also varies depending on the material characteristics and conveying requirements. Special pitch designs may require custom molds, which can affect the price.

Industrial Screw Conveyor Suppliers

As a source manufacturer, Macherise offers competitive prices for Industrial Screw Conveyors. For specialized processes, we provide a variety of structural options, including U-shaped trough conveyors, tubular conveyors, shaftless conveyors, twin-shaft screw conveyors, and medium-sized screw conveyors. Customization is available based on specific requirements such as conveying length and angle, trough material, screw blade material, and heating, cooling, explosion-proof features, and variable frequency speed control. We provide comprehensive services from equipment selection to after-sales maintenance.

Industrial Screw Conveyor Price is a function of many factors. When selecting equipment, it's crucial to prioritize its precise fit for the specific application. Specifically, the most suitable equipment type should be determined based on the material's physical and chemical properties, required conveying volume, and site space constraints. For example, when lifting materials, consider choosing between inclined and vertical types. For industries with stringent hygiene requirements, a specific grade of stainless steel is essential.