Cement Screw Conveyor Price

Tuesday December-09 2025 16:04:02

Cement Screw Conveyor Price from $2,000 to $5,000 or even higher, depending on various factors, including screw diameter and length, and the materials used, such as standard carbon steel versus more corrosion-resistant or wear-resistant stainless steel. Small to medium-sized models like the LS160 and LS200, with conveying distances under 10 meters, typically cost between $2,500 and $5,000; medium to large models like the LS250 and LS315, with conveying distances of 20-30 meters, range from approximately $7,000 to $12,000; and larger, specially customized equipment for longer distances can exceed $15,000. Furthermore, whether the equipment uses a closed tubular or open trough structure, and whether it includes a central shaft, will also affect the complexity of the process and the number of components required.

What are the types of Cement Screw Conveyor Price?

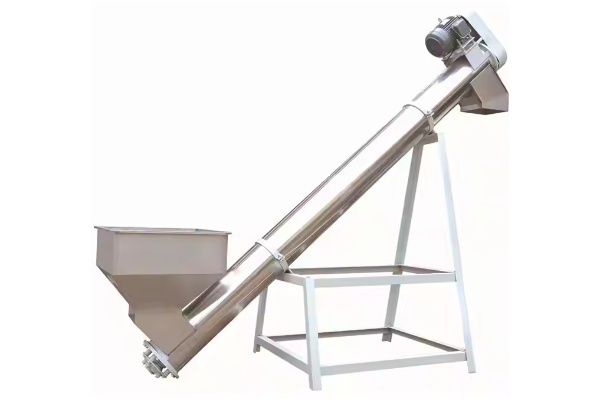

Cement screw conveyors are commonly used to transport powdery materials such as cement, fly ash, and lime. They come in many varieties, mainly divided into tubular and trough types. Tubular conveyors can be fitted with flanges, while trough conveyors can also be fitted with flanges, but the latter is less convenient. The following will detail these types, considering price and specifications.

A tubular Cement Screw Conveyor consists of helical blades enclosed within a circular steel tube. A motor and reducer drive the helical blades to rotate, conveying material from one end to the other. Tubular Cement Screw Conveyors are typically more expensive than trough conveyors. Common tube diameters include 168 mm, 219 mm, 273 mm, and 325 mm. Larger diameters result in greater conveying capacity. Lengths are customizable, ranging from 3 meters to 30 meters. Conveying capacities generally range from 10 tons per hour to over 100 tons per hour, depending on the tube diameter, pitch, speed, and material properties. Horizontal conveying is optimal. Inclination angles are typically limited to 45°, but special designs can achieve 60° or higher. However, conveying efficiency decreases with increasing angle. Power typically ranges from 2.2 kW to 22 kW.

A trough-type Cement Screw Conveyor, also known as a U-shaped screw conveyor, has helical blades rotating within a U-shaped trough. This design makes the internal structure clearly visible, facilitating inspection and cleaning. The price of a trough-type Cement Screw Conveyor is typically lower than that of a tubular conveyor with equivalent conveying capacity. The typical trough width corresponds to the helical diameter and affects the conveying capacity. The length is similar to that of a tubular conveyor and can be customized upon request. The conveying capacity is comparable to that of a tubular conveyor, depending on the helical diameter, rotational speed, and material characteristics. It is primarily used for horizontal or small-angle conveying, typically not exceeding 20°. Large-angle conveying can cause material to fall back, reducing efficiency.

Cement Screw Conveyor Price Table

| Parameter Type | Tubular Screw Conveyor | U-Trough Screw Conveyor | Shafted Screw Conveyor | Shaftless Screw Conveyor |

|---|---|---|---|---|

| Structural Features | Enclosed circular pipe structure, dust-proof and leak-proof | Top-open U-shaped trough structure, easy to maintain | Spiral blade with central shaft, high versatility | Shaftless, ribbon-shaped spiral, anti-wrapping |

| Diameter / Trough Width | φ100–φ500 (common φ168, φ219, φ323) | φ150–φ400 (U-trough width varies) | φ100–φ450 | Spiral diameter: 150–470 mm |

| Typical Length | 1–20 m (customizable) | 1–25 m | 1–20 m | 1–25 m (depending on model) |

| Motor Power | 0.75–15 kW | 0.75–15 kW | 0.75–15 kW | 0.75–22 kW |

| Available Material | Carbon steel / 304 / 316L stainless steel | Carbon steel / Hot-dip galvanized / 304 stainless steel | Carbon steel / 304 stainless steel | Carbon steel / Hardox wear-resistant steel / 304 stainless steel |

| Conveying Capacity | 5–150 m³/h (≈4–120 t/h) | 1–80 m³/h (≈1–60 t/h) | 3–120 m³/h (≈2.5–90 t/h) | 2.4–65 m³/h (common models: 2.4,7,13,28 m³/h) |

| Conveying Angle | 0–45° (common 0–30°) | 0–45° (commonly 0–30°) | 0–45° (generally ≤30°) | 0–30° (suitable for low-angle conveyance) |

| Reference Price | US$ 1,000 – 40,000 (small to large) | US$ 1,000 – 20,000 | US$ 800 – 15,000 | US$ 575 – 6,000+ |

What factors influence Cement Screw Conveyor Price?

The price of a Cement Screw Conveyor is influenced by a complex set of factors, including equipment size and conveying capacity, carbon steel, stainless steel, wear-resistant materials, tubular or trough type, shafted or shaftless, drive system configuration, conveying angle, and whether other customization features and brands are offered.

The diameter of the helical blades and casing is a key parameter determining conveying capacity. A larger diameter generally means higher conveying capacity, but also increases manufacturing costs. The overall length of the conveyor directly affects the amount of steel, helical shaft, bearing housings, and other components required. The longer the length, the higher the material costs and processing fees. Higher conveying capacity typically requires a larger diameter, a more powerful motor, and a more robust structure, which in turn increases the Cement Screw Conveyor Price.

Carbon steel is inexpensive and a commonly used material suitable for conveying general dry powders. Stainless steel is significantly more expensive than carbon steel, often several times the price. Stainless steel has excellent corrosion resistance and abrasion resistance, making it suitable for applications with special requirements for hygiene, corrosion resistance, or abrasion resistance. For conveying highly abrasive materials, the helical blades or troughs may be made of special wear-resistant alloy steel or undergo surface hardening treatment, which increases costs.

Cement Screw Conveyor Price Supplier

Currently, cement screw conveyor suppliers are concentrated in countries such as China, Germany, and the United States. Chinese suppliers have a cost advantage in conveyor manufacturing and a complete industrial chain. For example, Machrise, a manufacturer, provides both standard and customized conveyors. As a source manufacturer, Cement Screw Conveyor Price offers high cost-performance and fast delivery. German and American equipment is known for its precision design, durability, and excellent performance, especially under long-distance, high-torque, and harsh operating conditions. For high-performance equipment, German and American brands are recommended; for flexible customization, Chinese manufacturers are preferable.

Cement Screw Conveyor Price Solution

A cement plant needed to horizontally transport fly ash from a storage tank to a mixer over a distance of 15 meters, with a conveying capacity of 20 tons per hour. Based on the material characteristics and operating conditions, a U-shaped LS200 cement screw conveyor was adopted. The price of the Cement Screw Conveyor is approximately $4,000. After being put into operation, the conveying capacity was increased, and the space constraints and leakage prevention requirements were effectively resolved.

The Cement Screw Conveyor exhibits numerous advantages in cement conveying. For example, its enclosed structure helps reduce dust spillage and maintain a healthy on-site environment. Furthermore, the equipment occupies a relatively compact footprint, adapting to diverse site layouts. In daily operation, it operates relatively smoothly and demonstrates excellent adaptability for the continuous conveying of powdered materials. Furthermore, Cement Screw Conveyor Price is influenced by factors such as material handling volume, conveying distance, installation space limitations, and sealing requirements. These factors should be carefully considered when selecting a model to ensure that the equipment investment matches the actual application scenario.