Granulator Feed Bucket Elevator

The price of a granulator feed bucket elevator varies greatly depending on the model (TH or NE), lifting height, conveying capacity, material, etc. It ranges from US$100 to US$6,000.

Height: Max.40 meters

Bucket speed: 1.2 m/s

Bucket width: 315mm

Transmission type: belt/chain/chain plate

Lifting capacity: 0-60m3/h

Material: Stainless steel/Carbon steel

What is Granulator Feed Bucket Elevator?

Common types of Granulator Feed Bucket Elevator include the TH-type chain bucket elevator and the NE-type plate chain bucket elevator. These two types of equipment differ in their technical specifications. For example, the TH-type elevator typically has a conveying capacity between 10 and 480 cubic meters per hour and a lifting height of up to 30 meters, making it suitable for medium-scale production needs. The NE-type elevator, on the other hand, offers greater handling capacity and a lifting height exceeding 50 meters, meeting the material transfer requirements of high-capacity production lines. Choosing the appropriate bucket elevator depends on the specific material handling capacity and conveying height requirements of the actual production process.

What types of Granulator Feed Bucket Elevator are available?

Common bucket elevator types for Granulator Feed Bucket Elevator include the TH-type chain bucket elevator and the NE-type plate chain bucket elevator. Each type has its own unique characteristics, differing in technical specifications and applicable ranges.

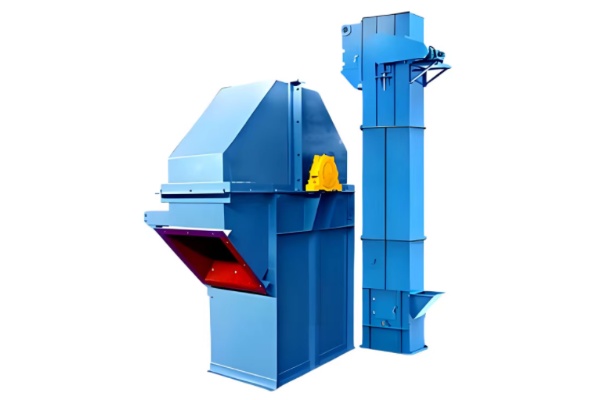

TH-type chain bucket elevator

Technical Parameters: Lifting height, typically between 4 and 30 meters. Capacity, ranging from 10 to 480 cubic meters per hour, is suitable for production lines with medium and higher outputs. Chain type, using round chain for high strength, is suitable for conveying materials with higher specific gravity. Hoppers, with wide spacing between hoppers, offer high conveying efficiency. Operating speed, operating at a relatively high speed.

Features: Compact structure and small footprint, allowing for optimal space utilization. High conveying capacity, with a large hopper and high operating speed, ensures high conveying efficiency, meeting the needs of most feed production lines. Excellent sealing, with a sealed housing design, effectively prevents dust from escaping. Maintenance is easy, with relatively simple inspection of transmission components and chains, minimizing daily maintenance. It offers wide applicability, suitable for conveying powdered, granular, and small, bulk materials, especially those with higher specific gravity.

NE Plate Chain Bucket Elevator

Technical Parameters: Lifting height: Typically higher than the TH type, reaching over 50 meters, or even exceeding 80 meters, making it suitable for high-rise factories or specialized process requirements. Capacity: A wider range of capacity is available, meeting diverse production needs, from low to ultra-high output. Chain: Plate chain, consisting of bushing roller chain and accessories, is durable. Hoppers: Numerous hoppers are closely arranged, enabling continuous lifting of materials. Operating speed: Slow, but with high throughput.

Features: High throughput: Due to the closely arranged hoppers and their large capacity, the NE type elevator achieves exceptionally high throughput, meeting the material handling needs of large-scale production. Low breakage rate. Its slow operation and gravity unloading method minimize impact on the material, making it particularly suitable for conveying fragile pellet feeds and effectively reducing the breakage rate of finished products. Its excellent sealing and enclosed housing design prevent material leakage during the lifting process. High reliability and a sturdy plate chain structure ensure long service life and low failure rate.

What are the advantages of a granulator feed bucket elevator?

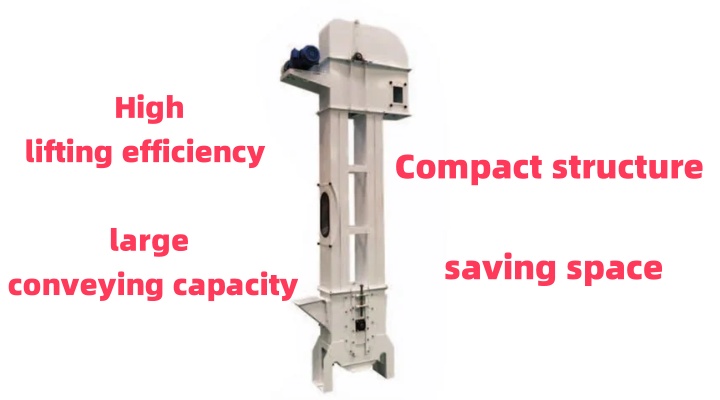

Granulator feed bucket elevators play a vital role in production lines, featuring high lifting efficiency, large conveying capacity, compact structure, excellent sealing, and reduced material damage. Their core advantages lie in the following:

High lifting efficiency and large conveying capacity: A bucket elevator uses a hopper to continuously or intermittently draw material from the bottom, then lifts it to a desired height at high or low speeds before discharging it. This design enables high-volume vertical conveying of material. For production lines like feed pelletizing, which require continuous and stable material supply, this lifting capacity ensures a smooth production process.

Compact structure and space saving: Bucket elevators have a small footprint and can fully utilize vertical space. Within a factory layout, they can transport material from the ground or lower levels to elevated silos, pellet mills, or other equipment, effectively saving valuable floor space and making the overall production line layout more compact and rational.

Excellent sealing and hygienic safety: Bucket elevators typically feature a fully enclosed casing. This effectively prevents dust from spilling during material conveying, improving the workshop working environment. For industries like feed production, which place high demands on hygiene, enclosed conveying methods effectively prevent secondary contamination of materials.

Stable Operation and Easy Maintenance: The sturdy structure and highly reliable transmission components ensure minimal daily maintenance, primarily focusing on tensioning and lubricating the chain or belt. This stable and reliable operation reduces the risk of production line downtime and ensures continuous production.

Reduced Material Damage: The NE-type plate chain bucket elevator, in particular, operates at a slower speed and uses gravity discharge, minimizing impact on pellet feed and significantly reducing material breakage during the elevator process. This is particularly important for production lines that demand high-quality, high-integrity finished feed.

Granulator Feed Bucket Elevator Parameters

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

How does a Granulator Feed Bucket Elevator work?

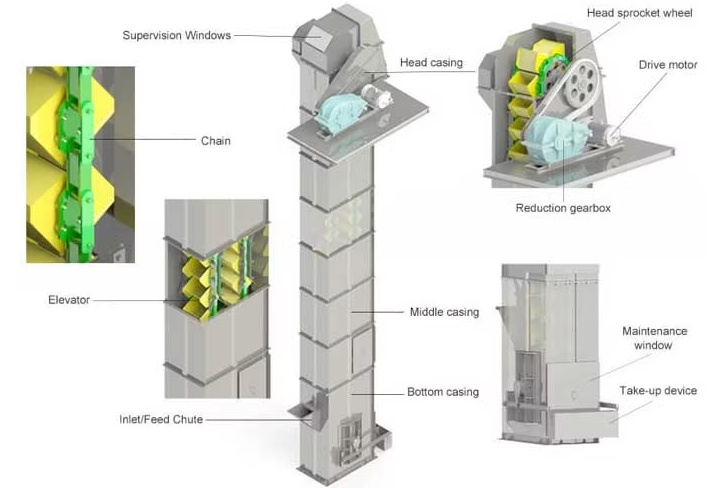

A granulator feed bucket elevator primarily consists of a housing, transmission, hopper, chain or belt, and tensioning device. The operation begins at the bottom of the elevator. Material enters the base through the inlet. When the elevator chain or belt, driven by the transmission, begins to move, the attached hopper enters the material pile at the bottom and is filled with material through scooping or gravity. As the chain or belt continues to move upward, the filled hopper is lifted. Throughout the entire lifting process, the material is conveyed vertically within the enclosed housing, effectively preventing dust and material contamination. When the hopper reaches the top of the elevator (i.e., the head section), the chain or belt passes over the head pulley. As it passes the head pulley, centrifugal force or gravity forces the material in the hopper to discharge through the discharge port. The specific discharge method depends on the type of elevator. Centrifugal discharge (such as the TH type) is suitable for faster elevators, where the material is thrown out by centrifugal force. Gravity discharge (such as the NE type) is suitable for slower elevators, where the material pours out smoothly under its own gravity, reducing the risk of material damage. After discharge, the empty hopper continues to descend to the bottom of the machine base and is refilled, repeating this cycle to achieve continuous vertical conveying of materials. The entire system uses a tensioning device to ensure the normal operation of the chain or belt and prevent slack. This simple cycle ensures a stable and uninterrupted supply of material to the feed pellet mill.

What are the applications of a granulator feed bucket elevator?

A granulator feed bucket elevator is a type of vertical conveying equipment whose core function is to lift bulk materials from low to high locations. Due to this characteristic, it has a wide range of applications. Any vertical movement of materials can be performed using a bucket elevator.

Warehousing and conveying systems: In large warehouses, logistics centers, or transfer stations, bucket elevators lift materials from the ground or receiving hoppers to elevated storage silos or towers for subsequent packaging, sorting, or further processing.

Material transfer on production lines: In multi-story or multi-process production lines, bucket elevators are key equipment for transferring materials across floors or equipment. For example, they can lift raw materials from a feed inlet on the first floor to a mixer on the second floor, and then lift the mixed materials to processing equipment on the third floor. This application simplifies production processes, reduces manual handling, and improves overall automation. Material Mixing and Batching: In processes requiring the precise mixing of multiple materials, bucket elevators can extract different raw materials from their respective storage bins and lift them to elevated batching hoppers. Gravity or metering equipment then precisely batches the materials before they enter the mixing equipment.

Waste Treatment and Recycling: In certain waste treatment or recycling scenarios, bucket elevators can lift debris, powder, or small pieces of waste from collection points to elevated processing equipment or recycling bins for automated processing.

Drying and Cooling Systems: When materials need to pass through drying or cooling equipment, bucket elevators can lift them to the top of these devices, allowing them to pass through the equipment under gravity to complete the drying or cooling process.

The selection of a granulator feed bucket elevator requires comprehensive consideration of the production process, including the material characteristics, required lifting height, and hourly material throughput. The TH-type elevator, with its compact structure and compatibility with a wide range of materials, has been used in many small and medium-sized production lines. The NE type elevator plays a key role in large feed mills due to its high handling capacity and low breakage rate for fragile materials. The technical parameters and working principles of these two types of equipment determine their applicability in different production environments.