Screw Feed Hopper

The price of Screw Feed Hopper varies significantly due to its model, material, processing capacity, degree of customization and manufacturer, usually ranging from $200 to $6,500.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

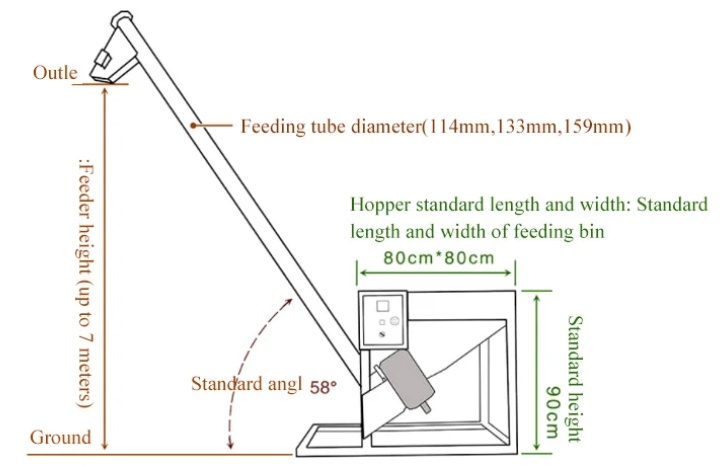

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

What is Screw Feed Hopper?

The main function of Screw Feed Hopper is to complete the reception, storage and stable transfer of bulk materials to subsequent process links. This type of equipment usually consists of a conical or square hopper and a screw conveyor. According to the structure and application requirements, Screw Feed Hopper can be divided into inclined type, vertical type and other types, and can be made of various materials such as stainless steel or carbon steel to adapt to different material characteristics and environmental conditions. In actual operation, its material handling capacity ranges from several cubic meters to tens of cubic meters per hour, and the conveying distance is usually limited to a few meters to more than ten meters, which is suitable for short or medium distance material conveying tasks.

What are the types of Screw Feed Hopper?

Screw Feed Hopper is usually used in combination with a screw conveyor to form a complete feeding system. They are of various types and can be divided from different angles. According to the classification method of installation angle and manufacturing material, they can be divided into inclined Screw Feed Hopper, stainless steel Screw Feed Hopper, carbon steel Screw Feed Hopper, etc.

Inclined Screw Feed HopperThe screw conveying part of the inclined Screw Feed Hopper is tilted upward at a certain angle, lifting the material from the bottom of the hopper to a specified height before discharging. The hopper itself may also be designed to be inclined or tapered to facilitate the flow of materials into the screw. When it is necessary to lift materials from a lower position to a higher position, such as lifting bulk materials from a ground storage hopper to a mixer, packaging machine or other processing equipment. The larger the inclination angle, the lower the conveying capacity will be, and the higher the fluidity requirements of the material will be. The motor power may also need to be increased accordingly to overcome the influence of gravity.

Stainless Steel Screw Feed HopperThe main structural components (such as hoppers, spiral blades, conveying pipes, etc.) are made of stainless steel (such as 304, 316L, etc.). Stainless steel has good corrosion resistance, wear resistance and easy cleaning. It is widely used in the food processing industry to convey grains, flour, sugar, seasonings, etc. to ensure that the materials are not contaminated and meet food safety and hygiene standards. It can convey materials with high purity requirements and corrosiveness to avoid chemical reactions or cross contamination between materials and equipment. Suitable for environments with damp, rainy or corrosive gases, such as some sewage treatment plants or chemical plants.

Carbon Steel Screw Feed HopperThe main structural components are made of carbon steel (such as ordinary steel such as Q235). Carbon steel has high strength and good processability. It is suitable for conveying bulk materials that are generally non-corrosive and have no special hygiene requirements, such as coal, mineral powder, sand, cement, lime powder, etc. In a dry environment, the rust prevention problem of carbon steel is relatively unprominent. Carbon steel is susceptible to moisture and rust, and is not suitable for materials with high hygiene requirements or corrosiveness. Surface treatment (such as painting) is usually required to improve corrosion resistance. The cost is relatively low.

What are the advantages of Screw Feed Hopper?

As an important material conveying equipment, Screw Feed Hopper has advantages in many aspects, making it an effective choice in a variety of industrial applications. These advantages together contribute to its specific role in the material conveying link. Its advantages mainly include:

Compact structure and space saving: The design of Screw Feed Hopper usually integrates material storage and conveying functions, and occupies a relatively small area. Especially in production environments with limited space, its compact structure can be better integrated into the existing equipment layout. Inclined Screw Feed Hopper can make better use of vertical space for material lifting, further saving horizontal space.

Stable conveying, material is not easy to be blocked: Screw Feed Hopper can continuously and evenly convey materials from the hopper to the designated position through the rotation of the internal spiral blades. For powdery, granular or poorly fluid materials, the propulsion of the spiral can effectively prevent the occurrence of "bridging" phenomenon (arched blockage of materials at the hopper outlet). Specially designed spirals (such as variable pitch spirals or ribbon spirals) can further enhance the adaptability to difficult-to-convey materials.

Closed conveying, reducing pollution and loss: Most Screw Feed Hoppers adopt a closed design, and the material is conveyed in the pipe or trough, which effectively avoids dust leakage, material spillage and external environment pollution of the material. This is particularly important for the transportation of materials with high hygiene requirements or susceptible to moisture, volatility, toxic and harmful materials, and can also reduce material loss.

Relatively simple maintenance and easy cleaning: Compared with complex belt conveyors or pneumatic conveying systems, the mechanical structure of the Screw Feed Hopper is relatively simple, with fewer vulnerable parts and less daily maintenance. For some models, such as those with segmented screws or quick-release designs, cleaning and maintenance are also more convenient.

Wide range of applicable materials: The Screw Feed Hopper can convey a variety of bulk materials, including powders, granules, small block materials, and even some semi-fluid or viscous materials. By selecting the appropriate spiral blade form (such as solid spiral, belt spiral, paddle spiral, etc.) and material (carbon steel, stainless steel), the conveying needs of different materials can be met.

How does the Screw Feed Hopper work?

The core working principle of the Screw Feed Hopper lies in the rotational motion of the spiral blade, which enables the material stored in the hopper to be continuously conveyed. A typical screw feed hopper system consists of three main parts: the feed hopper is the entrance and temporary storage area for the material, where the material falls to the bottom by gravity or external assistance (such as vibration); the screw conveyor is the core component of the system, which consists of a central shaft (or flexible screw) with spiral blades, installed at the bottom discharge port of the hopper and extending to the discharge end; the drive device (usually including a motor and a reducer) provides rotational power for the spiral blades. When the drive device is started, the motor drives the reducer, which in turn drives the spiral blades to rotate. During the rotation process, the spiral blades will continuously "scoop" up and push the material at the bottom of the hopper. Due to the relative movement between the spiral blades and the trough or pipe, as well as the gravity and friction of the material itself, the material is forced to be transported forward along the spiral direction driven by the blades. Specifically, under the push of the spiral blades, the material overcomes the friction resistance with the trough wall and its own internal, and moves axially in the direction of the spiral rotation. Once the material reaches the discharge port of the screw conveyor, it is pushed out of the equipment, completing the transfer from the hopper to the next link. This working mode gives Screw Feed Hopper several key features: first, forced conveying. Even if the material has poor fluidity or a certain viscosity, it can be effectively conveyed through the rotation of the screw, and it is not easy to "bridge" or block at the hopper outlet; second, continuity. As long as there is material replenishment in the hopper, the equipment can achieve uninterrupted conveying, which is suitable for production processes that require stable material flow; finally, controllability. By adjusting the screw speed (usually achieved through a frequency converter), the material conveying amount can be accurately controlled to meet the quantitative requirements of different processes for material flow. This simple and effective mechanical principle makes Screw Feed Hopper an important device for realizing material automation, stable feeding and conveying in many industrial fields.

Parameters of Screw Feed Hopper

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the applications of Screw Feed Hopper?

As a device that combines storage and conveying functions, Screw Feed Hopper has a wide range of applications and is suitable for a variety of scenarios where bulk materials need to be accurately or continuously fed. Their main function is to stably convey materials from one container or process point to the next link. It can convey powdered, granular, small block or crystalline materials such as cement, lime powder, grain, plastic granules, chemical raw materials, fertilizer, salt, sugar, etc. from the hopper at a set rate. This is essential for process flows that require precise control of material flow, such as in mixing, packaging or reactor feeding. When materials need to be transported from a lower position to a higher position, the inclined Screw Feed Hopper can play a role. It lifts and transfers materials from the ground or low-level silos to the feed port of high-level mixers, storage tanks, packaging machines or other processing equipment. For materials with poor fluidity, easy to agglomerate or adhere, the Screw Feed Hopper can effectively prevent the material from forming "bridges" or blockages at the hopper outlet through the forced pushing effect of the spiral blades, ensuring smooth discharge of materials. In scenarios where there are requirements for environmental hygiene and material purity, or where the material itself has characteristics such as dust, corrosiveness, and volatility, the closed design of the Screw Feed Hopper can effectively control material leakage, reduce dust pollution, and protect the material from the influence of the external environment, ensuring the cleanliness of the production environment and the quality of the material. In automated production lines, the Screw Feed Hopper is often used as a connection device for material flows between different equipment. For example, it can feed the material in the storage tank into the metering device, and then from the metering device to the mixer, ensuring the continuity and automation level of the entire production process. In general, the Screw Feed Hopper is mainly used in various occasions that require stable, controllable and often closed conveying of bulk materials, and is particularly good at handling materials that have poor fluidity or need to be lifted from low places.

As a material conveying tool, the design features of the Screw Feed Hopper enable it to handle a variety of bulk materials. Its closed conveying channel helps maintain the cleanliness of the material and limit the generation of dust in the operating environment. Through the continuous rotation of the spiral blades, the device can relatively stably transport materials from the hopper to the designated location, helping to avoid accumulation or interruption of materials at the discharge port. In actual deployment, the compact size of the Screw Feed Hopper enables it to adapt to different space configurations, and its operating mechanism is relatively straightforward, facilitating regular operation checks.