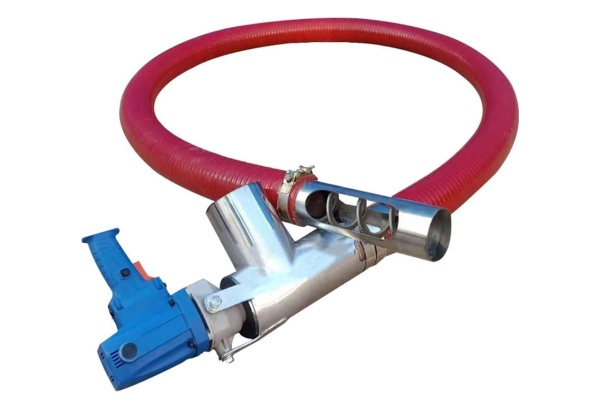

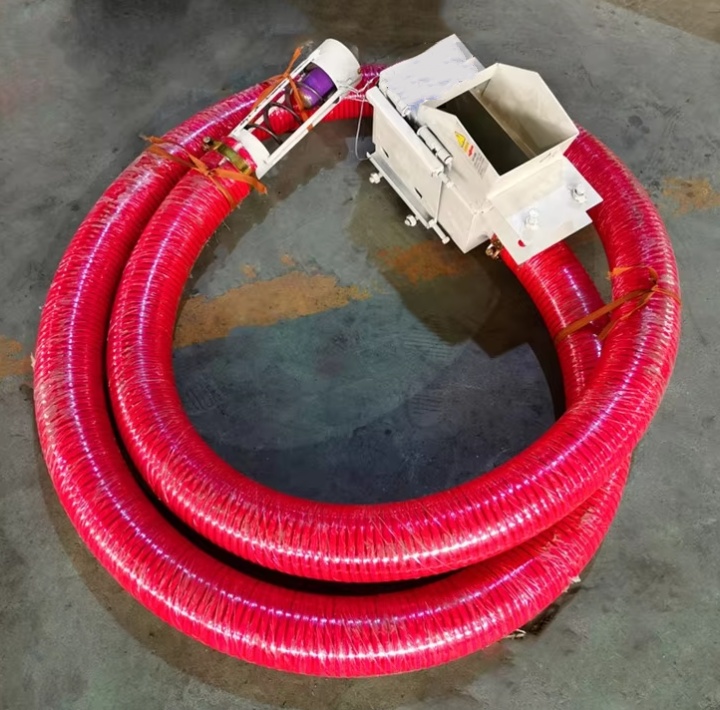

soybean suction grain conveying and feeding machine

The price of soybean suction grain conveying and feeding machine varies from USD 300 to USD 9,000, depending on the type, material, conveying capacity, etc.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 2T/h - 25 T/h

Length: 3 to 30 meters

Width or diameter: 100mm

Material: Stainless steel/Carbon steel

what is soybean suction grain conveying and feeding machine?

A soybean suction grain conveying and feeding machine uses mechanical or pneumatic means to suction, convey, and feed the soybeans. Various types of equipment are available on the market, primarily including pneumatic conveyors and screw conveyors. Their handling capacities typically range from 1 ton/hour to 30 tons/hour, and conveying distances can range from 1 meter to 20 meters or even longer. Specific configurations, such as the conveying pipe diameter and motor power, are adjusted based on specific application requirements and material characteristics. These devices play a role in various processes, including warehousing and processing.

What are the types of soybean suction grain conveying and feeding machines?

Soybean suction grain conveying and feeding machines are primarily used to transfer and feed soybeans from one location to another. Based on their operating principles and structural features, these machines can be generally categorized into the following main types:

Pneumatic ConveyorOperating Principle: A high-pressure blower or vacuum pump generates a high-speed airflow, which draws the soybeans into a conveying pipe. The airflow then conveys the soybeans to the designated location.

Features: Flexible conveying, with flexible pipes that can be bent freely, making it suitable for applications with limited space or requiring long-distance, multi-angle conveying. The soybean breakage rate is low, as the airflow conveying method minimizes physical damage to the soybeans, making it particularly suitable for seed or food-grade soybeans where integrity is critical. Easy to clean: the smooth interior of the pipe eliminates dead corners, making it easy to clean.

Working Principle: A motor drives spiral blades to rotate within a tube or U-shaped trough, pushing the soybeans forward.

Features: Simple structure, low maintenance, and reliable operation. Stable conveying capacity and controllable delivery volume make it suitable for production lines requiring stable and continuous feeding. Multiple types are available, including tube type (fully enclosed for dustproofing) and U-shaped trough type (easy to clean).

Mobile vs. Fixed

This classification is based on whether the equipment is mobile. Both types (pneumatic conveying and screw conveying) can be either mobile or fixed. Mobile conveyors have wheels on the bottom, allowing for flexible movement to different work locations. Features: Suitable for applications requiring frequent relocation, such as transferring soybeans between silos.

Fixed: The equipment is fixedly installed in a specific location, typically as part of a production line or storage system.

Features: The conveying path and position are fixed, making it easy to automate and streamline operations. It is commonly used in large grain and oil processing plants.

What are the advantages of soybean suction grain conveying and feeding machines?

Due to their unique operating principle and design, soybean suction grain conveying and feeding machines offer numerous advantages in the grain handling and processing industry, such as reduced material loss, guaranteed quality, strong adaptability, and flexible operation. The following are the main advantages of this type of equipment:

Enclosed Conveying: Most grain conveyors utilize fully enclosed pipelines, effectively preventing soybean damage caused by wind and spillage during transportation.

Reduced Breakage Rate: Pneumatic grain conveyors, in particular, use airflow to convey soybeans, reducing mechanical compression and collisions. This minimizes soybean breakage and helps maintain the integrity of the soybeans, which is particularly important for seed or food-grade soybeans. Contamination Prevention: The fully enclosed conveying system effectively isolates soybeans from dust, debris, and other contaminants, ensuring the hygiene and cleanliness of the material.

Flexible Conveying: The pneumatic grain conveyor's piping can bend and extend freely to adapt to the site's topography and spatial layout, making it ideal for use in narrow, complex, or long-distance conveying environments.

Easy Mobility: Many grain conveyors are designed to be mobile, equipped with wheels, allowing for easy movement to different work locations, increasing equipment utilization.

Multiple Uses: Many machines can convey not only soybeans but also a variety of granular materials such as corn, wheat, and rice, offering high versatility.

Dust Reduction: The enclosed conveying method controls dust generation and dispersion at the source, effectively improving the work environment and safeguarding the health of operators.

Parameters of Soybean Suction Grain Conveying and Feeding Machine

| Pipe diameter | Length | Voltage | Power | Efficient | Weight |

| 100mm | 3m | 220V | 3KW | 5-6t/h | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6t/h | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6t/h | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6t/h | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6t/h | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6t/h | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6t/h | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6t/h | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6t/h | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6t/h | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8t/h | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8t/h | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8t/h | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8t/h | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8t/h | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8t/h | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8t/h | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8t/h | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8t/h | 89kg |

| 120mm | 12m | 380V | 4KW | 7-8t/h | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6t/h | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6t/h | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7t/h | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7t/h | 200kg |

What are the applications of soybean suction grain conveying and feeding machines?

Soybean suction grain conveying and feeding machines have a wide range of applications, primarily in various scenarios requiring the handling, storage, and processing of soybeans. The core function of this type of equipment is to safely transfer soybeans. For example, in grain warehouses, soybean suction grain conveying and feeding machines are key to automated operations. They can directly suck newly harvested or purchased soybeans from trucks into the warehouse for storage, or even empty them from within the warehouse to maintain ventilation and maintain quality. When soybeans need to be shipped out, the equipment can quickly load them onto trucks or transport them to the next processing stage, improving warehouse management efficiency. In various agricultural product processing plants, this equipment is used as a feeder on production lines. It conveys soybeans from the raw material silo to equipment such as washers, soaking tanks, or refiners, enabling continuous and quantitative feeding. In feed production plants, soybeans are a key protein ingredient. Grain suction conveying feeders transport soybeans from storage areas to equipment such as grinders, mixers, or pelletizers. Because this type of equipment can precisely control the delivery volume, it helps ensure accurate feed formulation and guaranteed end-product quality. In addition to these applications, this equipment is also widely used in the loading and unloading of bulk soybeans. Whether at docks, stations, or other logistics nodes, it can unload soybeans from or load soybeans onto transport vehicles (such as trucks, trains, or ships), thereby speeding up logistics turnover and reducing labor costs and material loss.

The practical application of a soybean suction grain conveying and feeding machine depends on the specific operating environment. Equipment selection should consider soybean characteristics, such as moisture content and integrity requirements, as well as the site's spatial layout and conveying distance. Proper equipment configuration and routine maintenance are key to ensuring stable operation. This includes regular inspections of the motor, conveying piping, or spiral blades to ensure that all components are functioning properly. After a job is completed, cleaning the equipment, especially the piping and feed inlet, can prevent residue from affecting subsequent materials.