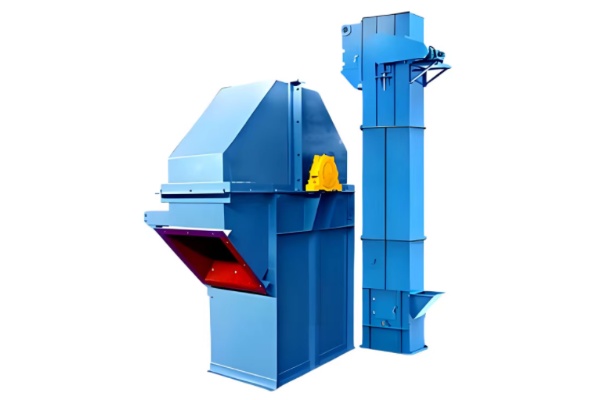

STST 304 Bucket Conveying System

The price of the STST 304 Bucket Conveying System varies depending on its model, configuration, conveying height, ranging from US$750 to US$6,500.

Frequency (HZ): 50HZ, 60HZ

Voltage: 220V, 380V, 440V, 480V

Capacity: 10 ~ 160 T/h

Dimensions (L×W×H): 550mm * 360mm * 8500mm/customized

Belt speed: 1.6m/s

Frame material: stainless steel/alloy

What is STST 304 Bucket Conveying System?

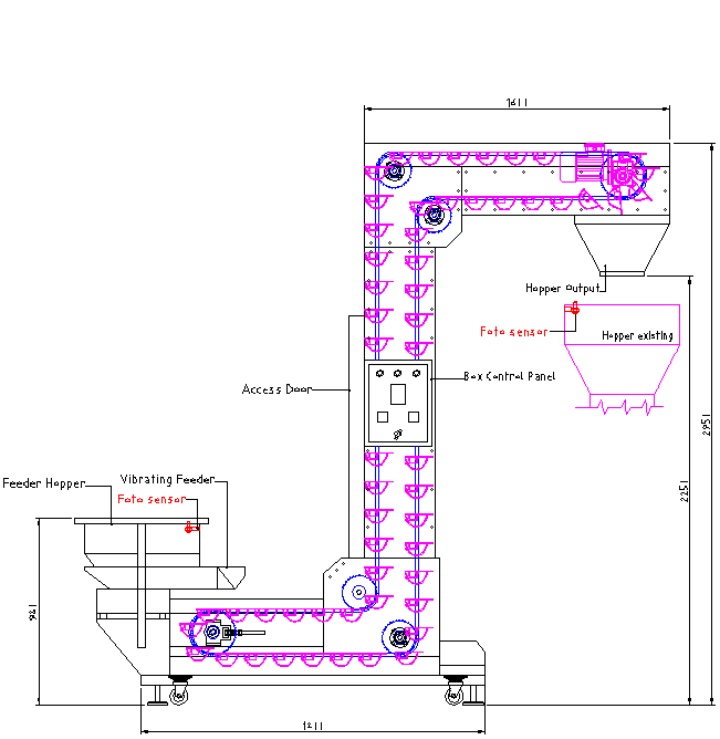

The STST 304 Bucket Conveying System is a device commonly used for vertical material conveying. Depending on the drive method, this system is primarily categorized into two types: chain and belt, each suited to different material characteristics and operating conditions. Chain systems are typically used to convey heavier or abrasive materials, while belt systems are more suitable for handling fragile or lightweight materials and offer relatively smooth operation. Some models can handle tens of cubic meters of material per hour. The STST 304 Bucket Conveying System, through a well-planned layout, can facilitate the transfer of materials between different pieces of equipment in various production environments and is an integral part of the material handling process in many production lines.

What are the types of STST 304 Bucket Conveying Systems?

The main types of STST 304 Bucket Conveying Systems are based on their drive method: chain drive and belt drive. Chain-type bucket conveyor systems attach the hopper to a double-strand roller chain, using the chain's motion to convey the material. A belt-type bucket conveyor system attaches a hopper to a continuous, endless belt, which is driven by the rotation of a pulley. The following is a detailed introduction:

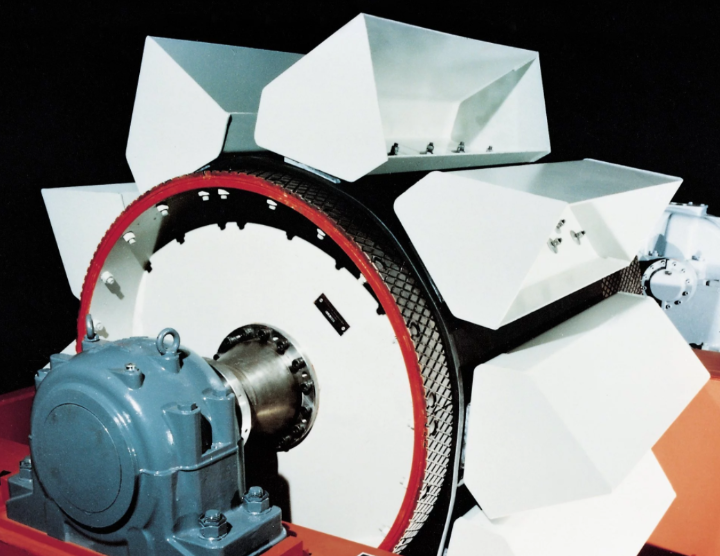

Chain-Type Bucket Conveyor System

Features

High Load-Bearing Capacity: Chains are stronger and more durable than belts, capable of withstanding heavier materials and greater shock loads. Therefore, they are often used for conveying heavy loads, high-density materials, and materials that are prone to abrasion.

High Temperature Resistance: Compared to belts, chain-type systems are more resistant to high-temperature environments and can be used to convey materials with temperatures exceeding 130°C.

Wear Resistance: Chains offer superior wear resistance when handling large particles and sharp corners.

Relatively Complex Maintenance: Due to the chain's structure, daily lubrication and wear inspections are relatively frequent, potentially leading to higher maintenance costs.

Technical Parameters

Material Particle Size: Suitable for conveying materials with larger particle sizes, typically handling materials larger than 50 mm.

Operating Speed: Compared to belt-type systems, chain-type systems typically operate at lower speeds.

Conveying Height/Distance: Some chain-type systems can achieve conveying distances of up to 70 m or more. Material: 304 stainless steel chain is often used to ensure corrosion resistance and hygienic standards, suitable for food-grade applications.

Belt-Type Bucket Conveyor System

Features

Smooth Operation and High Speed: Belt-type systems offer low noise and high speed, making them suitable for applications requiring high throughput.

Gentle on Material Handling: Due to their smooth operation, they are less damaging to fragile and easily brittle materials, making them more suitable for delicate material handling.

Easy Maintenance: Belt tensioning and inspection are relatively simple, requiring less frequent maintenance.

Technical Parameters

Material Particle Size: Ideal for conveying fine, lightweight, non-abrasive materials such as powders, granules, and grains.

Operating Speed: Achieves higher conveying speeds, thereby improving production efficiency.

Temperature Limits: Generally suitable for low-temperature environments below 100°C, but can withstand higher temperature peaks for a short period of time.

Material: Typically made of food-grade rubber, stainless steel core belts, or polymer materials. 304 stainless steel frames and hoppers ensure compliance with hygienic requirements.

What are the advantages of the STST 304 Bucket Conveying System?

The STST 304 Bucket Conveying System offers significant advantages across multiple industries thanks to its high hygiene and corrosion resistance, gentle material handling, space-saving vertical layout, and reliable and stable operation, all brought about by its 304 stainless steel construction. The following are its key advantages:

High Hygiene and Corrosion Resistance: Utilizing 304 stainless steel as the primary material, the system offers excellent corrosion and oxidation resistance, and is resistant to a wide range of acidic and alkaline media. Its smooth, easy-to-clean surface prevents material residue and bacterial growth, which is crucial for hygiene-critical industries such as the food and chemical industries.

Gentle Material Conveying, Reduced Breakage: The bucket conveying principle gently lifts and conveys materials, reducing impact on fragile and delicate materials, thereby effectively reducing breakage. The closed system design prevents dust contamination and preserves material purity.

Efficient Space Utilization: This system can handle a combination of vertical, inclined, and horizontal conveying, making it particularly suitable for factories with limited space, utilizing vertical space and conserving valuable floor space. High Reliability and Low Maintenance: The compact design allows for easy disassembly and maintenance, reducing the time and cost of routine maintenance.

The system operates stably and can be configured with a variety of safety features to ensure a safe and reliable production process.

Versatility and Customizability: A variety of feeding devices can be configured to meet different material characteristics (such as particle size and flowability) and production requirements, enabling single-point or multi-point feeding and unloading. The hopper and frame dimensions can be customized to suit different material conveying volumes and production scenarios.

Parameters of STST 304 Bucket Conveying System

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

What are the components of the STST 304 Bucket Conveying System?

The STST 304 Bucket Conveying System features a modular design. Its core structure consists of the following components: The hopper is made of 304 stainless steel, which is corrosion-resistant and easy to clean, making it ideal for industries with high hygiene requirements. The hopper is secured to the conveyor chain or belt using bolts or special connectors. The drive and conveyor system, consisting of a chain or belt, is the power transmission medium that drives the hopper. The STST 304 system offers two options: chain or belt, each suited to different operating conditions. The drive system, consisting of a motor, a reducer, and a drive sprocket or pulley, provides power to the entire system, ensuring the hopper moves at the desired speed and direction. The entire conveyor system is enclosed in a sealed casing, typically made of 304 stainless steel. This not only protects the internal components but also prevents the ingress of dust and foreign matter, ensuring the cleanliness of the material during conveying and preventing contamination caused by spillage. The feed port is where material enters the system and falls into the hopper. The design of the feed port typically takes into account the characteristics of the material to ensure smooth filling. The discharge port, when the hopper reaches the predetermined position, discharges the material by tilting or tilting. The STST 304 system can be configured with multiple discharge points to meet the needs of different production lines. The tensioning device adjusts the tension of the chain or belt to ensure proper operation and prevent deviation or slippage. The safety monitoring system includes various sensors, such as material level sensors and speed sensors, which are used to monitor the system's operating status in real time to ensure equipment safety and stable production.

What are the applications of the STST 304 Bucket Conveying System?

The STST 304 Bucket Conveying System is a versatile, highly efficient material handling device that plays a vital role in numerous applications. Its applications are broad, primarily focused on production environments with high hygiene requirements, requiring gentle material conveying, or limited vertical space.

Vertical conveying of bulk materials: It can lift materials stored on the ground floor to the top of overhead silos, mixers, or packaging machines, providing a continuous and stable supply of material for subsequent production processes. Whether it's granular, powdered, or flake materials, the system ensures they are free of contamination and minimizes material breakage during conveyance.

Inter-production line material transfer: The STST 304 Bucket Conveying System is often used to connect different equipment on a production line, enabling seamless material transfer. Its modular design allows the system to be customized to meet specific needs, enabling various configurations, such as single-point infeed, multiple-point outfeed, or multiple-point infeed, single-point outfeed, increasing production line flexibility and automation. Protecting Material Quality: Made of 304 stainless steel, the STST 304 Bucket Conveying System effectively prevents secondary contamination during conveying, making it particularly suitable for applications requiring stringent material purity. The enclosed housing not only protects the material but also prevents dust from escaping. Furthermore, its gentle handling of delicate materials makes it ideal for protecting product integrity.

STST 304 Bucket Conveying System Manufacturers

Manufacturers of STST 304 Bucket Conveying Systems typically offer a high degree of customization to meet the diverse needs of their customers. Manufacturers design their systems based on the material being conveyed. This includes the material's physical properties, such as particle size, density, flowability, and abrasiveness. For example, for delicate materials, manufacturers may utilize a smoother belt drive and specially designed hopper to minimize breakage. For heavy or abrasive materials, they may recommend a more robust chain system. The STST 304 Bucket Conveying System is not a standardized product; it is tailored to the customer's specific site and process flow. Depending on the factory's available space, the system can be designed with a combination of vertical, inclined, or horizontal layouts, utilizing vertical space and conserving valuable floor space. The manufacturer can also adjust the conveyor system's lift height and horizontal conveying distance to meet specific customer needs, ensuring precise docking between different equipment. The system can be customized to accommodate single-point infeed, multiple-point infeed, or single-point or multiple-point outfeed, adapting to varying material distribution and production processes. Customization is also available, with the manufacturer offering a variety of automation options. The control system can be configured with an advanced PLC, integrated with inverters, sensors, and other equipment, enabling precise control of conveying speed, real-time monitoring of material flow, and automatic fault alarms. Fully automatic or semi-automatic operation modes are available, reducing manual intervention and improving production efficiency and safety. Overall, the manufacturer of the STST 304 Bucket Conveying System provides customized services across multiple dimensions, from material handling and spatial layout to automated control, aiming to provide customers with a solution that meets their specific production needs.

The STST 304 Bucket Conveying System, with its customizable design, can adapt to a variety of complex production environments. The system can be adjusted based on specific conditions, such as material type, conveying height, and site space, to ensure smooth and continuous material conveying. Its 304 stainless steel construction meets industry-specific hygiene standards, preventing material contamination during conveying. The system's enclosed structure protects the material while controlling dust dispersion.