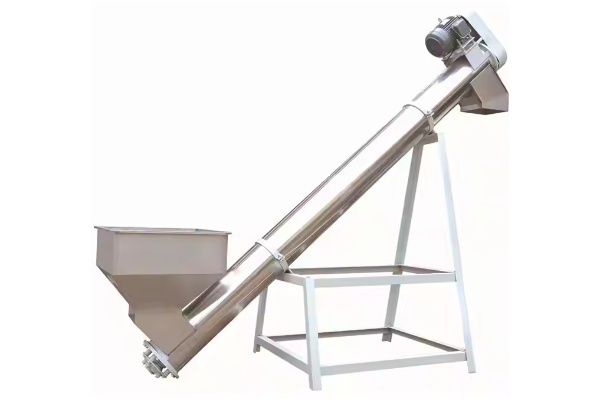

Pipe Screw Conveyors Transporting Powdered Sugar

The price of Pipe Screw Conveyors Transporting Powdered Sugar varies depending on its material, spiral diameter, and customized requirements. It usually ranges from $200 to $7,500.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

What is Pipe Screw Conveyors Transporting Powdered Sugar?

Pipe Screw Conveyors Transporting Powdered Sugar is a device used to transfer bulk materials such as powdered sugar in food processing environments. This type of conveyor mainly includes shafted and shaftless types based on its internal spiral structure; at the same time, it can be configured in various forms such as horizontal, inclined or vertical according to the conveying path. In terms of material handling capacity, Pipe Screw Conveyors Transporting Powdered Sugar can handle several cubic meters to tens of cubic meters of powdered sugar per hour, and the conveying distance of a single device usually ranges from several meters to more than 20 meters.

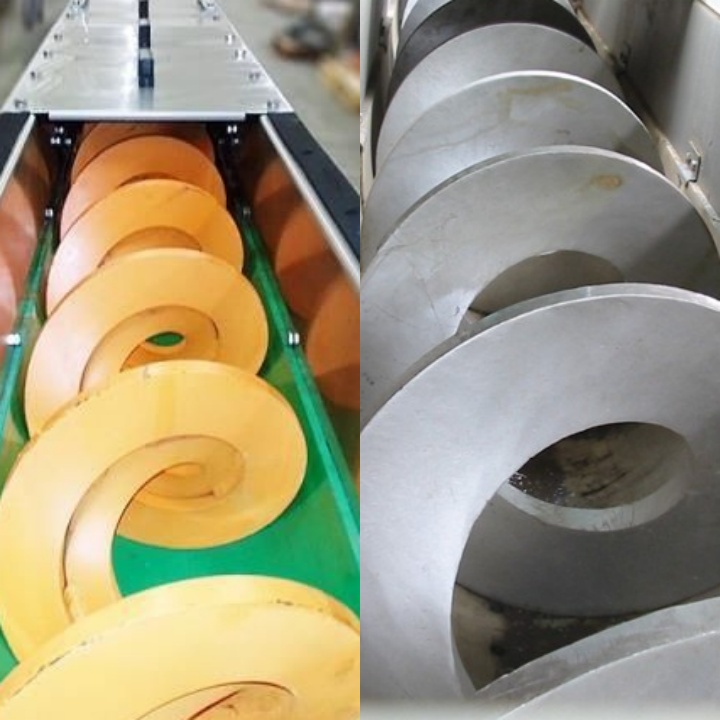

Due to the characteristics of powdered sugar, Pipe Screw Conveyors Transporting Powdered Sugar are primarily divided into two types: shafted and shaftless. Shafted screw conveyors are sturdy and suitable for conveying long distances or large volumes, but their central shaft can cause powdered sugar to stick or clump in some cases, compromising cleanability. Shaftless screw conveyors, on the other hand, effectively avoid this problem. Their open spiral design makes them easier to clean and can handle slightly sticky or tangled materials. They are therefore the preferred choice for conveying powdered sugar, especially in food-grade applications that require frequent cleaning or have strict hygiene requirements.

What are the types of Pipe Screw Conveyors Transporting Powdered Sugar?

Pipe Screw Conveyors Transporting Powdered Sugar is a specific application of tubular screw conveyors, which is used to transport materials such as powdered sugar that have high requirements for hygiene, moisture resistance and pollution prevention. Therefore, its type classification not only follows the general classification of ordinary tubular screw conveyors, but also places special emphasis on design choices related to the characteristics of powdered sugar.

Classification by spiral structure

Shafted screw conveyor

Features: The spiral blades are welded on the central shaft. For powdered sugar with good fluidity and not easy to agglomerate, the shaft structure can provide stable thrust. However, due to the presence of the central shaft, the risk of powdered sugar adhering to the shaft or bridging may be increased to a certain extent, especially under high humidity conditions.

Shaftless screw conveyor

Features: There is no central shaft, only a flexible screw body rotates in a U-shaped groove (or special tube). This is a common choice for conveying powdered sugar. The shaftless design greatly reduces the possibility of material adhesion and bridging, and is particularly suitable for conveying powdered sugar that is easy to agglomerate, sticky or has poor fluidity. Its larger conveying space also helps prevent blockage.

Classification by conveying angle

Horizontal tube screw conveyor

Features: The screw shaft is parallel to the ground. It is mainly used for long-distance or short-distance conveying of powdered sugar on the same horizontal plane, connecting different equipment or storage points.

Inclined tube screw conveyor

Features: The screw shaft is inclined at a certain angle to the ground. It can realize the lifting of powdered sugar from a low position to a high position, such as conveying powdered sugar to a high mixing tank, packaging machine feed port or silo. The inclination angle will affect the actual conveying capacity.

Vertical Tubular Screw Conveyor

Features: The screw shaft is perpendicular to the ground to achieve vertical lifting of sugar powder. In places with very limited space, sugar powder is lifted vertically to a higher position, but the material fluidity and equipment matching are required to be higher.

Classification by material

Stainless steel tubular screw conveyor

Features: The casing, spiral blades and other parts in contact with sugar powder are made of food-grade stainless steel (such as 304 or 316L). The surface is usually finely polished to achieve a mirror or matte effect to reduce material adhesion. This is the standard and first choice for conveying sugar powder. Stainless steel has excellent corrosion resistance and easy cleaning. It can meet the strict hygiene standards of the food industry, prevent material contamination, and withstand frequent cleaning and disinfection.

Carbon steel tubular screw conveyor

Features: The main body of the machine is carbon steel, but the contact surface with the material will be specially treated, such as spraying food-grade paint or lining with stainless steel. It is relatively low in cost compared to stainless steel, but it is rarely used directly in sugar powder transportation because there is a risk of coating peeling and contaminating sugar powder or incomplete cleaning. It is usually only considered in occasions where hygiene requirements are not extremely high or as an auxiliary conveyor.

What are the advantages of Pipe Screw Conveyors Transporting Powdered Sugar?

Aiming at the transportation needs of special materials such as powdered sugar, Pipe Screw Conveyors Transporting Powdered Sugar has the advantages of food-grade materials, moisture-proof and anti-caking, flexible conveying path, and less material loss. The following are its main advantages:

Excellent sanitation guarantee: This is the key advantage of conveying powdered sugar. Pipe Screw Conveyors Transporting Powdered Sugar are usually made of food-grade stainless steel (such as 304 or 316L). All surfaces in contact with powdered sugar are finely polished, smooth and without dead corners, and not easy to hide dirt. Its fully enclosed tubular structure effectively isolates the external environment, prevents dust, insects or other contaminants from entering, ensures the purity and sanitation of powdered sugar during transportation, and meets strict food production standards.

Effective moisture and anti-caking: Powdered sugar is very easy to get damp and agglomerate, affecting fluidity and even clogging equipment. The airtightness of the tubular screw conveyor can effectively prevent external moisture from entering and keep the powdered sugar dry. In addition, many powdered sugar conveyors adopt a shaftless spiral design, which reduces the obstruction and squeezing of the central shaft on the powdered sugar, greatly reduces the risk of powdered sugar agglomeration and bridging due to moisture or compaction during transportation, and ensures the smooth flow of materials.

Flexible conveying path: This conveyor can realize horizontal, inclined and even vertical material transportation. This allows powdered sugar to be lifted from a low position to a high position in a small space, or across different production areas, adapting to complex production line layouts, reducing the occupation of factory space, and simplifying the material transfer process.

Convenient cleaning and maintenance: Considering the cleaning requirements of the food industry, Pipe Screw Conveyors Transporting Powdered Sugar are usually designed to be easy to disassemble and clean. For example, the use of quick-open inspection ports, removable end covers or overall retractable spiral designs facilitates operators to thoroughly clean and disinfect the interior, ensure the cleanliness of the equipment, and prevent cross contamination and bacterial growth.

Reduce material loss: The fully enclosed conveying method reduces the possible spillage and flying of powdered sugar during the conveying process. This not only reduces material loss and saves production costs, but also improves the cleanliness of the workshop environment and avoids the impact of dust on equipment and personnel.

Basic parameters of Pipe Screw Conveyors Transporting Powdered Sugar

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the applications of Pipe Screw Conveyors Transporting Powdered Sugar?

Pipe Screw Conveyors Transporting Powdered Sugar is widely used in many links of the food industry because it can meet the strict transportation requirements of special materials such as powdered sugar. Its core advantage lies in providing hygienic and closed transportation solutions. For example, in the production of baking and pastries such as bread, cakes, biscuits, and candies, powdered sugar is an important ingredient. Tubular screw conveyors are used to transport bulk or bagged powdered sugar from storage silos, hoppers or ton bag unpacking machines to mixers/mixers. In the processing of solid beverages and dairy products, powdered sugar is a common sweetener or functional ingredient. In the production of solid beverages, powdered sugar needs to be transported to a mixing tank or filling machine to be mixed with other powdered ingredients to produce instant coffee, milk tea powder, juice powder, etc. In the production of dairy products such as yogurt and ice cream, powdered sugar is transported to the mixing or blending process. The production of chocolate and various candies requires high fineness and purity of powdered sugar. Powdered sugar needs to be transported to chocolate refiners or mixers to mix with cocoa liquid, cocoa butter, etc. to make chocolate paste. Or powdered sugar is transported to the sugar coating pan of candies or tablets for surface coating. Pipe Screw Conveyors Transporting Powdered Sugar also plays a role in the material receiving, storage and distribution of food factories. Bulk powdered sugar is transported from trucks or packaging bags to large storage silos, or taken out of silos and transported to production lines. Used in conjunction with a bulk bag unloading station or a small bag unpacking machine, the unloaded powdered sugar is safely transported to the processing equipment. In short, Pipe Screw Conveyors Transporting Powdered Sugar has become an ideal choice for handling powdered sugar and similar powdered materials in the food industry due to its closed, moisture-proof, easy to clean and food hygiene-enhancing characteristics. It is widely used in various production links that require precise, safe and continuous transportation.

Manufacturers of Pipe Screw Conveyors Transporting Powdered Sugar

In the field of Pipe Screw Conveyors Transporting Powdered Sugar, manufacturers not only provide standardized products, but more importantly, they demonstrate their customization capabilities to meet the strict requirements of the food industry for hygiene, moisture resistance and precise transportation. The type selection of Pipe Screw Conveyors Transporting Powdered Sugar usually revolves around its spiral structure, conveying angle and material. Common spiral structures include shaft and shaftless. Among them, the shaftless design is the preferred choice for conveying materials that are easy to adhere and bridge, such as powdered sugar, because it is not easy to entangle and agglomerate. In terms of conveying angle, manufacturers can provide horizontal type for plane transmission, inclined type for height difference lifting, and vertical type under specific space requirements. In terms of material, for food safety and hygiene considerations, food-grade stainless steel (such as 304 or 316L) is the standard configuration to ensure that the parts in contact with powdered sugar are clean and free of contamination. The core competitiveness of Pipe Screw Conveyors Transporting Powdered Sugar manufacturers lies in their strong customization capabilities, which enable them to provide a full range of solutions from design to manufacturing based on the specific needs of customers. For example, in terms of structural customization, the length, diameter, and inclination angle of the conveyor can be customized according to the on-site space and process flow, and even designed into a complex system with multiple feeding or multiple discharging points. In view of the easy adhesion of sugar powder, manufacturers will optimize the shape and pitch of the spiral blades, and even adopt a variable pitch design to ensure smooth flow of materials and prevent blockage. In addition to standard stainless steel, manufacturers can also provide specific grades of stainless steel and perform high-precision polishing (such as mirror polishing) on the surfaces in contact with the material to achieve a higher level of hygiene and minimize the adhesion and residue of sugar powder. In summary, when choosing a Pipe Screw Conveyors Transporting Powdered Sugar manufacturer, we should not only pay attention to the basic performance of its products, but also deeply examine its customization capabilities in dealing with complex working conditions and special hygiene requirements.

Pipe Screw Conveyors Transporting Powdered Sugar Case

Pipe screw conveyors transporting powdered sugar offer unique advantages in handling powdered sugar, making them widely used in the food industry. Powdered sugar, due to its fine, lightweight nature, hygroscopic properties, and its tendency to agglomerate, as well as the stringent hygiene and dust control requirements, makes pipe screw conveyors an ideal solution. For example, from storage bins/hoppers to processing equipment, bulk powdered sugar is conveyed from silos, bulk bag discharge stations, or small hoppers to subsequent processing equipment such as mixers, blenders, dissolvers, grinders, or extruders. This ensures continuous and automated production lines. From processing to packaging, processed powdered sugar (such as blended powdered sugar for specific food products) is conveyed from the processing area to packaging equipment such as fillers or baggers. A closed conveying system effectively prevents contamination and dust from forming before packaging. Even powdered sugar treated for anti-caking can still clump after prolonged storage or in humid environments. The continuous spiral motion of a tubular screw conveyor helps maintain the looseness of the powdered sugar during conveying. Powdered sugar dust is flammable, and contamination must be strictly controlled in food production. The fully enclosed design of the tubular screw conveyor effectively isolates the outside environment, preventing the ingress of dust and foreign matter while also preventing the escape of powdered sugar dust, thus ensuring food safety. Many food-grade pipe screw conveyors are made of stainless steel and are designed to be easily disassembled and cleaned, making them convenient for regular disinfection and maintenance to meet strict hygiene regulations. In short, pipe screw conveyors transporting powdered sugar have become indispensable conveying equipment in the food industry due to their comprehensive advantages in efficiency, cleanliness, safety (dust and explosion protection), and material protection.

Pipe Screw Conveyors Transporting Powdered Sugar plays the role of transferring sugar powder materials in the current food processing industry. The equipment realizes the continuous movement of powdered sugar by the rotation of spiral blades in a closed pipe. Its structural design focuses on the selection of food contact materials and easy-to-clean characteristics to maintain the sanitary environment of the production process and help control the humidity impact of the material during the transportation process. In occasions where powdered sugar needs to be transported and there are specific requirements for material cleanliness and operating environment, Pipe Screw Conveyors Transporting Powdered Sugar can provide a material transfer method that meets practical application needs.