Grain Screw Conveyor

The price of Grain Screw Conveyor varies greatly depending on its model, material, conveying capacity, drive system configuration. Its price ranges from US$100 to US$3,000.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

What is Grain Screw Conveyor?

Grain Screw Conveyor is a basic tool for achieving stable and continuous transfer of agricultural products. According to its structure and application scenarios, it can be divided into main types such as tubular type and U-shaped trough with cover type, each of which is adaptive to different environments and material characteristics. The amount of material it can handle ranges from several tons to hundreds of tons per hour, and the conveying distance can usually be flexibly adjusted within a few dozen meters, providing a convenient means for receiving, storing, processing and distributing grain. Whether it is feeding from silos to processing equipment or transferring materials between different processes of the production line, Grain Screw Conveyor plays an indispensable role.

What are the types of Grain Screw Conveyor?

Grain Screw Conveyor is a material conveying equipment designed for agricultural products and grain processing industries. According to its structure, installation method and the characteristics of the spiral blades, it can be divided into multiple types to adapt to different types of grain, different conveying distances and environments. According to its shell form, it can be mainly divided into tubular screw conveyors and trough screw conveyors. These two types have their own characteristics and are suitable for different grain transportation needs.

Tubular Screw ConveyorThe round tube can completely enclose the material, effectively prevent dust from spilling out, reduce material loss, and avoid external contamination of grain (such as dust and pests). This is crucial for materials such as grain that have high requirements for hygiene and cleanliness. It is usually more compact than a trough conveyor, especially when conveying vertically, it can significantly save space. The tubular design makes it more flexible when installed and can adapt to a variety of space layouts.

The U-type trough covered screw conveyor installs the spiral blades in a U-shaped (or V-shaped) trough body and is equipped with a tight cover on the top. It is suitable for medium to large conveying volumes, mainly used for horizontal or small inclination (usually not more than 20 degrees) conveying. The top of the trough is covered and sealed, which can achieve a certain sealing effect and reduce dust and pollution, but it is usually not as completely closed as a tubular conveyor.

Stainless steel grain screw conveyors are often known for their portability and flexibility, and are often referred to as handheld grain conveyors. Their core features lie in their construction and material. The main components are made of stainless steel, making the equipment corrosion-resistant and easy to clean. Their compact size and light weight make them easy to move and operate in various locations, making them particularly suitable for use in farms, small grain storage facilities, or for loading and unloading vehicles. The conveying angle and position can be adjusted as needed to accommodate a variety of work scenarios.

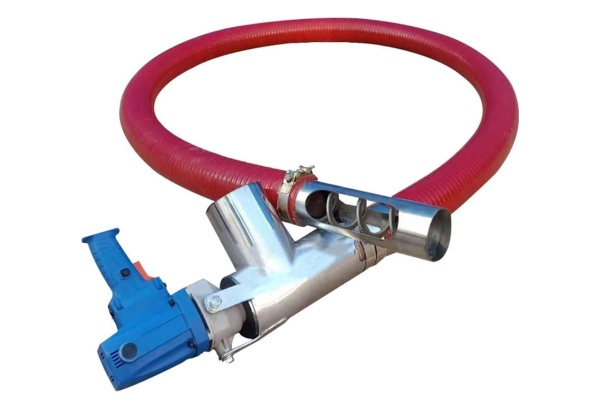

Hose Grain Screw Conveyor

Hose grain screw conveyors utilize a flexible hose as their housing. Their key feature is their flexible conveying path, offering high adaptability. The hose material generally offers excellent sealing properties, effectively preventing dust from escaping during conveying, making them suitable for applications requiring high hygienic conditions. Hose conveyors are also more lightweight and easy to install and disassemble. It is suitable for conveying dry, fluid, powdered or granular grains such as flour, grain, and feed.

What are the advantages of Grain Screw Conveyor?

Grain Screw Conveyor is widely used in the grain handling and processing industry. With its unique design and operation mode, it has shown many significant advantages, such as closed transportation, space saving, stable transportation, and wide adaptability.

Closed transportation: One of the core advantages of Grain Screw Conveyor. Whether it is a tubular or U-shaped trough design with a cover, it can achieve fully enclosed or highly enclosed transportation. This airtightness can prevent material contamination, prevent grain from contacting dust, insects, rodents or moisture during transportation, and ensure the cleanliness and hygiene standards of grain. Reducing dust pollution can effectively control the dust generated during grain transportation and reduce the risk of dust explosion. At the same time, it also avoids the spillage and waste of materials during transportation, and improves the utilization rate of materials.

Compact structure, space saving: The overall structure of the screw conveyor is relatively compact, especially the tubular screw conveyor. Compared with equipment such as belt conveyors, screw conveyors occupy less horizontal space at the same conveying capacity. It can be flexibly arranged in grain depots, processing plants or production lines with limited space, and can even achieve vertical or large-angle transportation, effectively utilize three-dimensional space, and simplify the process flow.

Stable transportation and reduced material segregation: The spiral blades rotate continuously in the trough body to push the grain forward smoothly. This conveying method reduces the impact on grain during the conveying process, helps maintain the uniformity of the material, reduces the segregation of materials with different particle sizes or densities, and ensures the stability of subsequent processing or product quality.

Wide adaptability, handling a variety of grains: The screw conveyor can adjust the spiral blade form, pitch and speed according to the type and characteristics of the grain. It can effectively convey various granular grains such as wheat, corn, rice, soybeans, and powdered processing by-products such as flour and bran. The shaftless screw conveyor can also handle some grain processing waste with a certain amount of moisture or viscosity, such as wine lees, wet bran, etc., to avoid entanglement and blockage.

What are the parameters of a grain screw conveyor?

Screw conveyor parameters

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

Grain Suction Machine parameters

| Diameter | Length | Voltage | Power | Capacity | Weight |

| 100mm | 3m | 220V | 3KW | 5-6T | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6T | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6T | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6T | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6T | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6T | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6T | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6T | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6T | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6T | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8T | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8T | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8T | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8T | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8T | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8T | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8T | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8T | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8T | 89kg |

| 120mm | 12m | 220V | 4KW | 7-8T | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6T | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6T | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7T | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7T | 200kg |

What are the applications of Grain Screw Conveyor?

Grain Screw Conveyor plays a vital role in the field of agriculture and grain processing, and its applications cover multiple links from field to table. For example, during the grain harvest season, it is used to quickly and conveniently transport grain from agricultural trucks, grain trucks or trailers to granaries or silos. In large grain depots, screw conveyors are important tools for transferring grain between different storage locations and adjusting storage positions. Through horizontal or inclined screw conveyor systems, grain can be transferred from one storage unit to another, which is convenient for ventilation, inspection, grading or preventing caking. In grain processing plants (such as flour mills, feed mills, starch mills, etc.), screw conveyors run through the entire production process, transporting raw grain from the receiving port to the primary processing links such as cleaning equipment and stone removers; conveying flour, bran, corn kernels, soybeans and other materials in different forms between various processing steps such as cleaning, peeling, grinding, mixing, drying and cooling; used to accurately convey raw materials of different proportions to mixers or batching silos to achieve automated and continuous production; conveying processed finished grain or feed pellets to packaging workshops or bulk loading points. In feed production enterprises, screw conveyors are used for raw material proportioning, conveying various feed raw materials such as corn, soybean meal, bran, additives, etc. from their respective silos to mixers. Convey pressed feed pellets to coolers or finished product silos. In summary, Grain Screw Conveyor plays an irreplaceable role in all aspects of grain reception, storage, processing and transportation due to its closed and stable characteristics, ensuring the smooth flow and quality control of grain throughout the supply chain.

Grain Screw Conveyor Case Studies

Grain screw conveyors, as a type of bulk material conveying equipment, are widely used in various processes. Their core function is to move materials horizontally, diagonally, or vertically. Their applications primarily include material transfer and loading and unloading, material lifting and distribution, material mixing and processing, automation, and closed-loop conveying. Screw conveyors are commonly used when grain needs to be moved from one location to another. For example, in the fields, they can load harvested grain directly from the ground into transport vehicles. In warehouses, they can transfer grain from one storage area to another, enabling fast and labor-saving material transfer. Their flexible deployment options, whether fixed or mobile, can adapt to loading and unloading needs in various environments. Screw conveyors are also particularly effective when grain needs to be lifted to a higher level. It can transport materials from the ground to hoppers, silos, or processing equipment, meeting the height requirements of production lines. Using a diverter, a single screw conveyor can distribute materials to multiple outlets, enabling multi-point material delivery and centralized control. While conveying materials, a screw conveyor can also perform some simple processing tasks. Its specially designed blades enable uniform mixing of different materials being conveyed, making it particularly useful in producing mixed feed, premixes, and other products. Furthermore, it can serve as a quantitative feeding device, controlling the material delivery rate by controlling the speed, thereby achieving precise control of production ratios. In applications with stringent environmental hygiene requirements, tubular screw conveyors can provide a fully enclosed conveying environment. This structure effectively prevents dust and contamination, while also minimizing material loss. These application scenarios demonstrate the versatility and practicality of the Grain Screw Conveyor for handling bulk materials.

Grain Screw Conveyor has become an indispensable equipment in agriculture and grain processing due to its inherent characteristics in material transportation. It can complete the transfer task of powdered or granular grain materials in a relatively controlled environment. The selection and configuration of the equipment needs to be determined based on the specific type of grain, the required conveying volume, the spatial conditions on site and the requirements for material cleanliness. By selecting the appropriate screw diameter, length, material and drive mode, this type of conveyor can be reliably integrated into the existing production process and provide a stable material conveying path.