Plastic Granule Vacuum Loader

Plastic Granule Vacuum Loader, an automated conveying device based on the negative pressure suction principle, is becoming a standard feature in injection molding, extrusion, blow molding, and other processes due to its core advantages of being airtight, dust-free, and flexible.

Power: 1.5-5.5 kW (customizable)

Dimensions (L*W*H): Depends on the specific model

Material: 304/316 stainless steel

Voltage:220V/380V/415V or customizable upon request

Customization: Acceptable

Type: Pneumatic/Electric/Continuous

Core Components: Motor, bearings, gears, pump, gearbox, engine

Applicable Materials: Pigments, carbon black, PP, PE granules, ABS raw materials, resin granules, and plastic granules

What is a Plastic Granule Vacuum Loader?

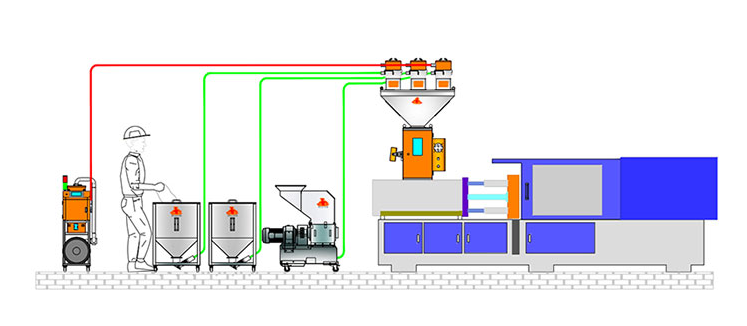

Plastic Granule Vacuum Loader is an automated conveying device designed for the plastics processing industry. Its core goal is to address the challenges of low efficiency, pellet breakage, and dust contamination during the transfer and feeding of plastic pellets. Powered by an oil-free vacuum pump or vacuum generator, it creates a stable negative pressure within a closed system. Using the air pressure differential, pellets are drawn from the storage silo. After separation of air and material through a metal mesh filter, they are precisely conveyed to equipment such as injection molding machines and extruders.

Most of the equipment's material-contacting components are constructed of 304 stainless steel, with a mirror-polished interior to prevent sticking and scratching. It also features a large-diameter suction nozzle and a steeply curved elbow to minimize pellet breakage and accommodate plastic pellets with varying characteristics. The fully enclosed conveying process is dust-free and spill-free, ensuring pellet integrity while promoting clean, automated production in plastics workshops. It is a key piece of equipment connecting all stages of plastics production.

What are the advantages of the Plastic Granule Vacuum Loader?

The Plastic Granule Vacuum Loader, with its unique design and technological advantages, has become a core piece of equipment for conveying plastic pellets in modern industry. Its advantages are reflected in multiple dimensions, including increased efficiency, cost optimization, safety, and environmental friendliness.

Precise Feeding: The device can be linked to the material level sensors of injection molding machines, extruders, and other main machines to achieve automatic start/stop and flow control.

Reduced Loss: Closed conveying prevents material spillage, and combined with high-precision filters, raw material loss can be reduced from 3% to below 0.2%.

Explosion-Proof Design: Given the static-sensitive nature of plastic pellets, the device utilizes anti-static piping and is equipped with a grounding device to effectively prevent explosions caused by static electricity accumulation.

Multi-Material Compatibility: It can convey plastic pellets of varying sizes and moisture levels, and even handle mixtures of powder and pellets.

Plastic Granule Vacuum Loader Exclusive Design

The Plastic Granule Vacuum Loader's core competitiveness lies in its deep adaptation to the physical properties of plastic pellets. From its structure to its materials, the loader is engineered to be "breakage-resistant, anti-sticking, and easy to clean."

Material Compatibility: The hopper and piping that come into contact with the material are made of 304 stainless steel, with a mirror-polished interior. This prevents scratches from friction between the plastic pellets and the metal, while also reducing particle adhesion and residue.

Structural Damage Prevention: The suction nozzle features a large-diameter arc transition design to prevent particle breakage due to impact when entering the pipe. The conveying pipe utilizes a large-curvature elbow to reduce friction and compression at the inflection point, ensuring intact particle shape.

Anti-Blocking and Cleaning: The hopper bottom utilizes a combined "conical" design with a pneumatic discharge valve. The tapered design optimizes the flow properties of plastic pellets and prevents bridging and blockage within the hopper. The device supports "quick disassembly," with the hopper and piping connected by clamps, allowing for tool-free assembly and disassembly.

Plastic Granule Vacuum Loader Operating Principle

The Plastic Granule Vacuum Loader utilizes an oil-free vortex vacuum pump or compressed air generator as its power source. It extracts air from the closed conveying system, creating a stable negative pressure environment and conveying pellets via a pressure differential.

Negative Pressure Suction: After the equipment is started, the system's negative pressure creates a pressure difference with the external atmospheric pressure, causing plastic granules to be drawn from the storage silo into the conveying pipeline through a dedicated suction nozzle. The airflow drives the granules smoothly, preventing gravitational settling and pipeline blockage.

Air-Material Separation: Particles follow the airflow into the separation hopper, where they are intercepted by a metal mesh filter element, achieving air-material separation.

Precision Unloading: When the granules in the hopper reach the preset material level, the system automatically starts and stops according to the target equipment's material consumption rate to prevent granule accumulation.

Plastic Granule Vacuum Loader Customization

Plastic processing scenarios are diverse, and the Plastic Granule Vacuum Loader offers flexible customization to meet diverse production needs.

Multi-station and long-distance conveying: For simultaneous feeding of multiple injection molding machines, a customizable "one-to-many" system can be used, utilizing pipe switching valves to precisely feed different equipment. For long-distance conveying across workshops, the vacuum pump power can be upgraded and combined with larger-diameter pipes to ensure efficient pellet conveying.

Adaptable to high temperatures and special pellets: For high-temperature plastic pellets freshly pelletized, the equipment seals are constructed with heat-resistant fluororubber, and the hopper can be insulated to prevent damage to components.

Automated linkage: Equipped with a PLC control system, the equipment can be linked with injection molding machines, extruders, and other equipment. When the target equipment's hopper is low on material, the loader automatically starts to refill; when full, it automatically shuts down, achieving unattended operation.

Plastic Granule Vacuum Loader Technical Parameters

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

Plastic Granule Vacuum Loader Production Scenarios

From feeding multiple injection molding machines in the injection molding workshop, to transferring PP and PE granules in extrusion/pelletizing lines, to delivering ABS raw materials in the blown film plant, the Plastic Granule Vacuum Loader's sealed, loss-resistant design adapts to diverse scenarios, enabling unmanned operation and reducing costs and improving efficiency.

Injection Molding: In the production of 3C electronic product casings, the vacuum loader precisely delivers plastic granules of different colors to multi-component injection molding machines, reducing color changeover time from 15 minutes to 2 minutes.

Extrusion Lines: When used with single-screw extruders, the device can adjust the conveying speed via variable frequency control to ensure a constant material level in the extruder hopper and avoid strand breakage caused by insufficient feeding.

Chemical Raw Material Handling: When conveying ultrafine powders such as pigments and carbon black, the device uses a coated filter bag to effectively prevent material leakage.

Why is the Plastic Granule Vacuum Loader essential for plastics processing?

In plastics processing, the Plastic Granule Vacuum Loader eliminates pellet loss and dust contamination associated with manual feeding, prevents pellet breakage associated with mechanical conveying, and can also be linked with injection molding/extrusion machines for automated feeding.

Improving Efficiency and Automation: 24/7 uninterrupted automatic feeding relieves employees from heavy, repetitive manual labor, allowing one person to manage multiple production lines.

Ensuring Product Quality: Fully enclosed conveying effectively prevents the infiltration of impurities such as dust and moisture, avoiding contamination caused by manual feeding, and ensuring product purity and consistency. Optimizing the Workshop Environment: This completely eliminates the dust problem caused by manual material feeding, making the production workshop cleaner and more environmentally friendly while also ensuring employee respiratory health.

Flexible Layout and Centralized Management: Flexible equipment installation and extendable piping allow for easy centralized material supply.

Reducing Overall Costs: Although a one-time investment, the long-term benefits from reduced labor costs, reduced material waste, and improved product yield far outweigh the investment.

Plastic Granule Vacuum Loader Customer Case Studies

As a manufacturer of plastic granule vacuum loaders, we serve clients across various industries. We provide tailored plastic granule vacuum loaders tailored to their needs and production sites.

Automotive Industry: Faced with the challenge of material conveying across three floors of a factory building, traditional manual handling resulted in low efficiency and severe dust pollution. By deploying a customized vacuum loader, utilizing 304 stainless steel anti-static piping and a PLC automated control system, the system achieved a vertical conveying capacity of 3 tons/hour over a distance of 15 meters.

Food Industry: A food packaging company experienced high rejection rates for PET preforms due to metal debris contamination in its screw conveyor. The introduction of a clean vacuum loader, featuring 316L stainless steel, food-grade silicone seals, and an oil-free vacuum pump, keeps residual microbial counts below 10 CFU/cm².

The chemical industry: Production requires frequent changes in glass fiber reinforcement, flame retardant formulations, and other ingredients. Traditional equipment takes two hours to change and is prone to clogging. The intelligent vacuum loader enables quick 5-minute changes in modular piping. Combined with an IoT module, this increases formulation change efficiency by 12 times.

Plastic Granule Vacuum Loader Manufacturer

We provide high-speed, intelligent plastic granule vacuum loader solutions for customers in the plastics processing industry. We offer customized explosion-proof, cleanroom, and intelligent equipment for diverse applications, such as automotive parts, food packaging, and chemical modification. We support personalized configurations, including 304/316L stainless steel, modular piping, and IoT integration. We cover a full range of conveying capacities from 0.1 to 20 tons/hour. Core technologies such as pulse backflushing and an oil-free vacuum pump ensure airtight, dust-free, stable, and low-energy operation.

The Plastic Granule Vacuum Loader, with its comprehensive advantages of high speed, safety, and environmental protection, not only solves the pain points of traditional conveying methods, but also becomes a key equipment for enterprises to achieve intelligent manufacturing and green transformation. It is the "standard configuration" for plastic processing companies to move towards automated and intelligent manufacturing.