What is the purpose of a screw feeder?

Saturday July-12 2025 10:27:15

Screw Feeder is a mechanical device used to convey bulk materials. It pushes powdered, granular and small block materials in a closed or open trough in a specific direction through rotating spiral blades. Its main uses include: achieving quantitative feeding of materials to meet the requirements of material ratio in subsequent processes; or in some cases, providing a closed conveying environment for materials to reduce dust, prevent pollution or isolate risky materials. The current application of screw feeder covers a variety of material transmission needs in the production process and is a common material handling tool.

What are the uses of screw feeder?

Screw feeder is used in many industrial fields due to its relatively simple structure, easy maintenance and controllable conveying capacity. Its main purpose is to achieve material metering, conveying and auxiliary functions in specific process links. The following are common uses of screw feeder:

Quantitative feeding of materials: By adjusting the speed of the screw, the amount of material conveyed per unit time can be controlled. When used in conjunction with weighing sensors, frequency converters and control systems, screw feeders can achieve accurate metering of materials to meet the strict requirements of material proportions in processes such as batching, mixing and packaging. This quantitative feeding capability is advantageous in production lines that require multiple materials to be mixed in proportion.

Continuous conveying of materials: Screw feeders can provide a continuous flow of materials and reduce efficiency losses caused by intermittent operations. It is suitable for processes that require uninterrupted production to ensure the stable operation of subsequent equipment. For example, at the feed end of a dryer, reactor or incinerator, continuous feeding can maintain a stable amount of material inside the equipment, thereby optimizing process parameters.

Closed conveying of materials: For materials that are easy to generate dust, toxic, harmful, deliquescent or react with air, closed screw feeders can provide a closed conveying environment. For example, when conveying powdery materials such as cement, fly ash, and lime powder, closed conveying can effectively control dust.

Mixing and stirring of materials: In some cases, screw feeders can also play a certain mixing or stirring role while conveying materials. By designing a special spiral blade shape or introducing other stirring devices during the conveying process, preliminary mixing can be performed while the material is being conveyed, which is particularly useful for materials that need to be pre-mixed.

Cooling or heating of materials: Specially designed screw feeders can control the temperature of the conveyed materials by passing cooling or heating media into the shell or screw shaft. For example, in the conveying process of some materials that need to be cooled (such as high-temperature clinker), the screw feeder can be used as a cooling conveying device. Conversely, the material can also be preheated.

Unloading of storage equipment: The screw feeder can be installed at the bottom of the silo, hopper or silo and used as a unloading device. It can evenly and stably convey the material in the silo to the next link, avoid clogging or arching of the material in the silo, and ensure smooth outflow of the material. For materials with poor viscosity or fluidity, it may be necessary to equip an arch-breaking device.

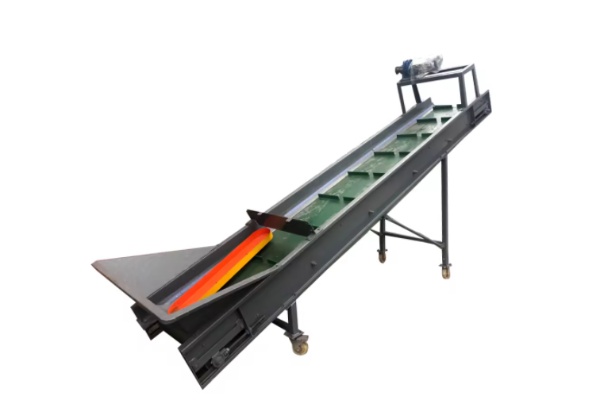

Lifting conveying: Within a certain angle range, the screw feeder can realize inclined conveying of materials, or even vertical conveying (usually requiring special structures such as tubular screw feeders or vertical screw elevators). This is practical in situations where plant space is limited or materials need to be transported to a high place. By changing the installation angle and pitch, its conveying capacity can be adjusted.

As a mechanical conveying equipment, Screw feeder undertakes the functions of material transmission, metering and auxiliary processing in various industrial production processes. Its application in different industries provides a feasible solution for handling various types of bulk materials. In practical applications, the selection of a suitable Screw feeder model requires comprehensive consideration of the properties of the material itself (such as particle size, density, viscosity, abrasiveness, corrosiveness, temperature, etc.), as well as specific requirements such as conveying volume, conveying distance, installation angle, working environment and conveying accuracy. The evaluation of these factors helps to determine the specific parameters and configuration of the equipment to ensure that it can meet current production needs.