Automatic Vacuum Loading Machine

Automatic vacuum loaders use a vacuum pump to generate suction, enclosing materials from storage to production equipment. This process is dust-free and environmentally friendly, eliminating cross-contamination.

Power: 1.5-5.5 kW (customizable)

Size (length * width * height): Depends on the specific model (customizable)

Material: stainless steel / carbon steel

Voltage: 220V / 380V / 415V or as ordered

Type: pneumatic / electric / fully automatic / explosion-proof

Scope of application: Conveying materials such as flour, wheat flour, sugar, milk powder, seasoning, coffee beans, etc.

What is an automatic vacuum loader?

Automatic Vacuum Loading Machine utilize the principle of vacuum and negative pressure to fully automate material transfer. They seamlessly integrate with production equipment such as mixers, packaging machines, and reactors. Through sealed pipes, they precisely deliver materials like powders and granules to their target locations, revolutionizing traditional manual or mechanical conveying. Made of stainless steel, they support customization requirements such as explosion-proof and aseptic quality, making them an ideal choice for modern intelligent production!

What types of automatic vacuum loaders are there?

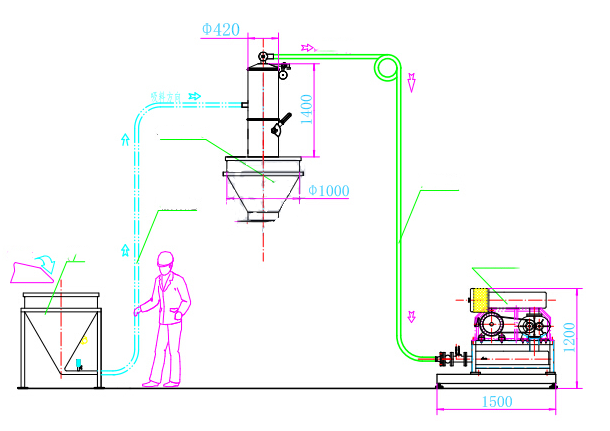

Automatic vacuum loaders can be categorized as either split or integrated. Split types feature independent components, making them suitable for long-distance, complex conveying. Integrated types are compact and ideal for shorter, smaller spaces.

Split types utilize a modular design, consisting of independent vacuum pumps, hoppers, conveying piping, and control systems, allowing for flexible component placement. Their advantage is that the vacuum pump can be installed away from the production area, effectively reducing the impact of noise and heat on the material.

Integrated types integrate the vacuum pump and hopper into a compact structure, making them easy to move and simpler to install and operate. This type is suitable for shorter conveying needs.

What are the advantages of automatic vacuum loaders?

Automatic vacuum loaders offer significant advantages. Their fully enclosed conveying system prevents dust contamination and is suitable for a wide range of industries and materials. Their automated operation reduces labor costs and improves efficiency. Their intelligent control system is easily integrated, contributing to the advancement of modern industrial conveying.

High degree of automation: Unattended operation is possible after parameter settings are set, and conveying efficiency is 3-5 times that of manual feeding.

Strong material adaptability: Whether it's free-flowing plastic granules, easily agglomerated nanopowders, or even sticky materials containing sugar or oil, stable conveying can be achieved by adjusting the vacuum level, pipe inclination, or adding a vibration device.

Boosted production efficiency: Deep integration with PLC control systems enables adjustable suction and discharge cycles from 0 to 30 seconds, and supports simultaneous feeding of multiple devices.

Innovative space utilization: The compact design reduces the equipment's footprint by 65% compared to traditional conveying systems, making it particularly suitable for space-constrained environments such as cleanrooms and high-bay warehouses.

Automatic Vacuum Loader Operating Principle

Automatic vacuum loaders operate based on a "negative pressure suction - positive pressure discharge" cycle. After the equipment is started, a vacuum pump quickly creates negative pressure within the enclosed pipeline, drawing material from a silo or container into the conveying pipeline through a suction nozzle. When the material reaches the separation tank, a filter intercepts the powder, preventing it from entering the vacuum pump. The material then falls into the storage hopper under gravity. The system then automatically switches to positive pressure, opening the discharge valve at the bottom of the storage hopper, allowing the material to enter downstream equipment, completing a conveying cycle.

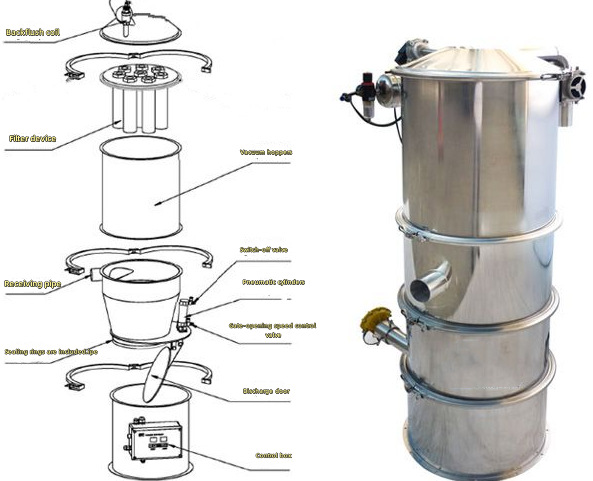

What are the main components of an automatic vacuum loader?

An automatic vacuum loader primarily consists of a vacuum generation system, a suction and conveying assembly, a separation and filtration device, a storage and unloading unit, and an intelligent control system, working together to achieve negative pressure suction and automated conveying of materials.

The vacuum generation system: Powered by a vacuum pump, models with varying vacuum levels are available depending on the material's characteristics.

The suction and conveying assembly: Includes the suction nozzle and conveying pipeline. The pipeline diameter is typically 25-100 mm, suitable for materials of varying particle sizes (5μm-5mm).

The separation and filtration device: The separation tank utilizes a cyclonic separation principle and is equipped with a high-precision filter to ensure stable exhaust dust levels. Storage and Unloading Unit: Optional storage hopper capacity ranges from 5 to 50L, equipped with a level sensor. The unloading valve utilizes a pneumatic butterfly valve or ball valve.

Intelligent Control System: PLC + touchscreen control allows for setting the loading volume and conveying cycle, and supports remote start/stop and fault alarms.

Model Specifications

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

Automatic Vacuum Loader Application Scenarios

Automatic vacuum loaders are widely used in the pharmaceutical, food, chemical, plastics, and new energy industries, enabling dust-free, efficient, and automated conveying of materials such as powders, granules, and tablets.

Pharmaceutical Industry: Vacuum loaders are suitable for conveying materials such as API powders, granules, and capsules. Their fully enclosed system prevents cross-contamination, enabling high-precision metering and dust-free conveying of powders during aseptic filling.

Food Industry: For powders and granules such as flour, milk powder, and food additives, the vacuum loaders feature a sealed design to prevent dust leakage and ensure food hygiene.

Chemical Industry: They can convey chemical raw materials such as pigments and resin powders. They are suitable for handling corrosive, flammable, and explosive materials, and support inert gas protection such as nitrogen. Plastics Industry: Used for conveying plastic pellets, masterbatches, and more, reducing pellet breakage and loss, and enabling continuous production.

Agriculture: Assists in conveying agrochemicals, feed, fertilizer, and other materials, promoting agricultural automation.

Choose us as your automatic vacuum loader supplier?

Choose us as your automatic vacuum loader supplier and we offer customized solutions. Intelligent IoT integration ensures efficient operation, inherently safe design, and long lifespan, giving you peace of mind when conveying materials.

Technology from multiple industries: With extensive experience in 12 major industries, including pharmaceuticals, food, chemicals, and new energy, we develop customized conveying solutions tailored to the specific material characteristics. From sticky powders to flammable and explosive particles, we offer mature and stable industry-adaptable solutions.

Intelligent Control and IoT Integration: Equipped with an intelligent control system, the equipment features an adjustable suction and discharge cycle from 0 to 30 seconds, enabling visual monitoring of conveying volume, energy consumption, and other data. Vibration and pressure monitoring provide 48-hour advance warning of faults, minimizing downtime. Intrinsically safe design: Certified explosion-proof and equipped with static elimination and inert gas protection systems, it safely transports flammable and explosive materials such as potassium nitrate and aluminum powder.

Long life and low maintenance: The modular design allows for quick replacement of core components like the filter element and vacuum pump in just 5 minutes. The conveying pipes feature ceramic lining or polyurethane coating, extending their service life by three times.

Automatic vacuum loading machine price

Automatic vacuum loading machine prices start as low as $2,000, varying depending on type, configuration, material, and brand. Small, simple models are suitable for laboratories or small workshops and are affordable. Requirements for high throughput, corrosion-resistant materials, or specialized features such as explosion-proofing will increase in price. Consider your production scale, material characteristics, and budget when selecting a machine. We will provide professional guidance and pricing to help you select the right equipment within your budget.

Automatic vacuum loading machines, with their core focus on negative pressure suction, offer fully enclosed conveying, high automation, and strong adaptability, making them an ideal choice for material handling in various industries. From the cleanliness requirements of pharmaceuticals to the explosion-proof needs of chemicals, from the hygiene standards of food to the precise delivery of new energy, it can meet the characteristics of each scenario through customized design.