Cone Crusher

Adopts the lamination crushing principle, suitable for medium and fine crushing of various ores and rocks

Price: $200.00-$70,000

Feed size: 50-460mm

Discharge size: 8-65mm

Processing capacity: 30-1500t/h

What is Cone Crusher?

Cone Crusher is a medium-fine crushing mining machinery equipment that adopts the principle of laminated crushing. It is mainly used to crush various types of ores and rocks with medium or higher hardness. It can crush large pieces of materials to the ideal particle size. Its maximum feed particle size can reach 300mm, and its processing capacity is 80-1500 tons per hour. The discharge particle size can be adjusted according to different needs (usually 5-50mm, special models can reach less than 3mm). Cone crusher is particularly suitable for crushing high-hardness materials such as granite, basalt, iron ore, copper ore, etc. Through the unique hydraulic system and crushing cavity design, it can not only complete the crushing operation efficiently, but also ensure the excellent particle shape of the finished product (cubic content of more than 90%). At the same time, it has iron protection and automatic cavity clearing functions. It is widely used in sand and gravel aggregate production, metal mine beneficiation, construction waste treatment and other fields.

What are the categories of Cone Crusher?

According to the different structures and working principles, Cone Crusher can be divided into three types: spring, single-cylinder hydraulic and multi-cylinder hydraulic.

Spring Cone Crusher: uses a spring system to provide crushing force and overload protection, with a simple and reliable structure and low maintenance cost. It is suitable for small and medium-sized production lines, medium-hardness materials, feed size 35-300mm, discharge size 3-51mm, and processing capacity 5-1000t/h.

Single-cylinder hydraulic Cone Crusher: uses a single large-diameter hydraulic cylinder, with a small floor area, suitable for sites with limited space, feed size 30-350mm, discharge size 3-50mm, and processing capacity 5-1200t/h.

Multi-cylinder hydraulic Cone Crusher: uses multiple hydraulic cylinders to provide crushing force, and the hydraulic system realizes overload protection, discharge port adjustment and cavity clearing operation. It has high crushing efficiency and uniform product size. It is suitable for large and medium-sized production lines, high-hardness materials, feed size 35-460mm, discharge size 3-64mm, and processing capacity 40-1500t/h.

What are the advantages of Cone Crusher?

Cone Crusher adopts the principle of laminated crushing, so that the material is squeezed and impacted multiple times in the crushing chamber, greatly improving the crushing efficiency; its optimized chamber design can increase the crushing ratio and increase the output by more than 40% at the same power. The finished product has high-quality particle shape, and the unique parallel belt structure ensures uniform particle size, high cubic content, and few needle-like particles, which is particularly suitable for the production of high-quality concrete aggregates. The equipment operates stably and reliably, the multi-cylinder hydraulic system has an automatic overload protection function, and the thin oil lubrication combined with the labyrinth seal effectively prevents dust and significantly extends the bearing life. In addition, the cone crusher is flexible in adaptability. The coarse, medium and fine crushing modes can be adjusted by replacing the liner, and the hydraulic adjustment of the discharge port can be supported to quickly meet the requirements of different discharge particle sizes.

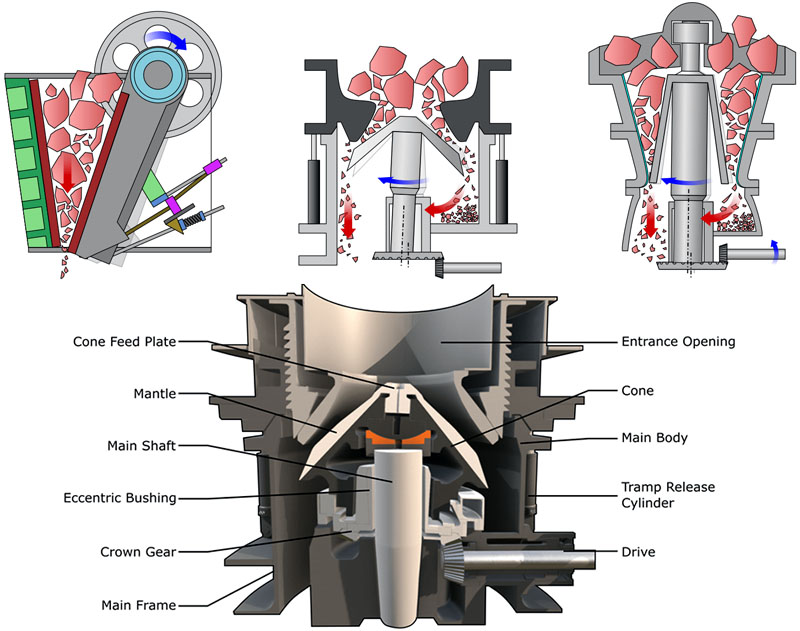

What is the working principle of Cone Crusher?

When the Cone Crusher is working, when the material enters the crushing body from the feed port, the motor drives the eccentric sleeve to select, forcing the moving cone to do a rotary swing motion. When the moving cone is close to the fixed cone, the material is squeezed and crushed. When the moving cone is far away from the fixed cone, the crushed material falls under the action of gravity, and the material that meets the particle size requirements is discharged from the bottom discharge port.

Cone Crusher parameters

|

Item Model |

Feeding capacity (t/h) | Maximum number of particles allowed for an object (mm) | Power (w) | Voltage (v) | Current (a) | Double amplitude (mm) | Gap (mm) | Total weight (kg) |

| GZ1 | 5 | 50 | 60 | 220 | 1≤ | 1.75 | 1.9-2.2 | 75 |

| GZ2 | 10 | 60 | 150 | 220 | 2.3≤ | 1.75 | 1.9-2.2 | 155 |

| GZ3 | 25 | 70 | 200 | 220 | 3.8≤ | 1.75 | 1.9-2.2 | 225 |

| GZ4 | 50 | 100 | 450 | 220 | 7≤ | 1.75 | 1.9-2.2 | 460 |

| GZ5 | 100 | 150 | 650 | 220 | 10.6≤ | 1.75 | 1.9-2.2 | 656 |

What is the difference between a Cone Crusher and a Jaw Crusher?

| Comparison items | Cone Crusher | Jaw Crusher |

| Crushing principle | Laminated crushing (extrusion + impact) | Extrusion crushing (moving jaw and fixed jaw bite) |

| Structural features | It is composed of a moving cone, a fixed cone, a hydraulicsystem, etc., and the structure is relatively complex | It is composed of a fixed jaw plate, a movable jaw plate, aneccentric shaft, etc., and the structure is simple |

| Applicable materials | Medium and high hardness materials (such as granite, basalt,iron ore, etc.) | Various hardness materials (soft, medium and hard, such aslimestone, pebbles, construction waste, etc.) |

| Feed particle size | ≤300mm (depending on the model) | ≤1500mm (large jaw crusher can handle larger pieces ofmaterial) |

| Discharge particle size | 3-60mm (adjustable) | 10-350mm (wide adjustment range) |

| Output | Medium to high (12-2000t/h) | Low to medium (1-2200t/h) |

| Finished particle shape | Better (more cubes, less needle-like) | Average (more needle-like) |

| Energy consumption | Higher (suitable for medium and fine crushing) | Lower (suitable for coarse crushing) |

| Maintenance cost | High (complex structure, replacement of wearing parts istroublesome) | Low (simple structure, easy maintenance) |

| Application scenario | Medium and fine crushing (secondary or tertiary crushing) | Coarse crushing (primary crushing) |

| Automation level | High (hydraulic adjustment, overload protection) | Low (mainly mechanical adjustment) |

What are the applications of Cone Crusher?

Cone Crusher can be used to crush natural ores such as granite, river pebbles, iron ore, copper ore, as well as medium and high hardness materials such as industrial solid waste such as steel slag and construction waste. Its feed particle size can reach 300mm. It is often used in sand and gravel aggregate production, metal mine beneficiation, construction waste treatment and cement raw material preparation.

Cone Crusher Price

The price of a cone crusher varies greatly depending on the model, material and configuration, and generally ranges from $5,000 to $20,000. For example, a small spring cone crusher (such as PYB600) costs about $4,000 to $25,000, while a high-efficiency multi-cylinder hydraulic model (such as HPT220) can cost up to $200,000 to $220,000. Second-hand equipment is cheaper, but is more affected by the degree of wear and tear.

Cone Crusher Manufacturer

We are the source manufacturer of Cone Crusher, providing different types such as single-cylinder hydraulic, multi-cylinder hydraulic, spring type, etc. Common models include HPC series (such as HPC-160, HPC-220), HP series (such as HP-400, HP-600), PSGB/PY series (such as PSGB1626, PYB2200), etc., to meet the different process requirements of coarse crushing, medium crushing and fine crushing. Our factory also supports customized services, and can adjust the discharge port size, crushing cavity type, motor power and other parameters according to customer needs, and adapt to the crushing requirements of different materials (such as iron ore, granite, limestone, etc.); We can also provide intelligent upgrade options according to user needs, such as remote monitoring and automatic adjustment system to optimize production efficiency.

Coarse crusher

Coarse crusher Minerals Coarse Crusher

Minerals Coarse Crusher  Micro-crushing machine

Micro-crushing machine