Vertical Form Fill Seal Packing Machines Price

Tuesday December-09 2025 10:22:10

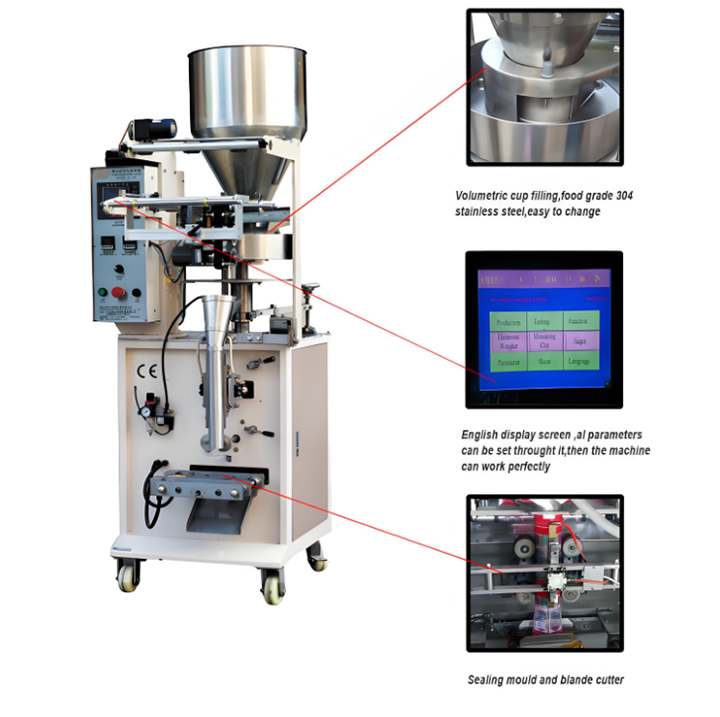

Vertical Form Fill Seal Packing Machines Price from $2,500 to $8,000, depending on the model, level of automation, and customization requirements. These machines are suitable for a variety of materials, including powders, granules, liquids, and sauces, and can typically pack at speeds of 30 to 70 bags per minute. They automate the entire process from film stretching, bagging, filling to sealing.

Vertical Form Fill Seal Packing Machines produce various types of packaging bags to meet your needs, including pillow bags, three-side seal bags, four-side seal bags, gusseted bags, and stand-up pouches. Their stainless steel construction ensures stability and durability, and some models are also equipped with servo control systems and photoelectric detection devices. Machine types include single-output, multi-output, and high-speed models; single-output machines are generally less expensive, while high-speed vertical packaging machines are the most expensive.

Different types of Vertical Form Fill Seal Packing Machines Price

Vertical Form Fill Seal Packing Machines Price is affected by many factors. The more complex the structure, the faster the packaging speed, and the stronger the production capacity, the higher the equipment cost and price, which jointly determine its pricing.

Single-spout vertical packaging machines have a relatively simple structure, typically using a single filling and sealing unit. They are suitable for small and medium-sized production lines. Their packaging speed typically ranges from 30-60 bags/minute, and their price range is approximately $3,000 to $6,000. This machine is suitable for customers with low production requirements and a high focus on cost control. They are suitable for materials with good flowability, such as powdered, granular, and flake forms, such as coffee powder, milk powder, dried fruit, candy, tablets, and tea.

Multi-spout vertical packaging machines have multiple filling and sealing units and can pack multiple bags simultaneously. They are suitable for large-scale production, with packaging speeds of 100-300 bags/minute. Their price range is between $6,000 and $9,000. This model is suitable for businesses with high production demands and a high degree of automation. They are suitable for materials such as granules, powders, liquids or sauces, flakes, and blocks. Equipped with a liquid filling unit, they can also pack liquids or sauces.

Designed for efficient production, the high-speed vertical packaging machine utilizes an advanced control system and high-speed operating mechanism, capable of packaging speeds exceeding 300 bags per minute. It is particularly well-suited for demanding industries such as snacks and powders, and is priced between US$9,000 and US$10,000. This machine offers high precision, high efficiency, and the ability to scale up to meet the demands of large-scale production. It is primarily used for packaging snacks, powders, granules, liquids, and sauces, such as puffed foods, potato chips, laundry detergent, milk powder, coffee beans, seeds, soy sauce, and salad dressing. Liquids and sauces require specialized filling systems.

Vertical Form Fill Seal Packing Machines Price Sealing Type Selection

Vertical Form Fill Seal Packing Machines offer sealing methods including heat sealing, cold sealing, and vacuum sealing. Heat sealing is the most common and suitable for most plastic films; cold sealing is used for heat-sensitive films, while vacuum sealing systems are suitable for products with high sealing requirements. Cold and vacuum sealing systems are more expensive due to their technical complexity and high cost. Higher packaging speeds increase the requirements for servo motors and control systems, leading to higher prices. Furthermore, multi-film machines that can accommodate multiple film materials are more expensive. Regarding metering systems, screw metering is recommended for powders, weight metering is suitable for granular materials, and piston pumps are used for liquids. The higher the metering accuracy and adaptability, the higher the Vertical Form Fill Seal Packing Machines Price.

What factors influence Vertical Form Fill Seal Packing Machines Price?

Factors influencing Vertical Form Fill Seal Packing Machines Price include material characteristics, production volume requirements, level of automation, bag type, and customization needs.

Material Characteristics: Different materials require different filling and sealing systems. For example, for conventional dry materials, the machine structure is simpler and the price is correspondingly lower. Powders may use a screw metering device. Complex materials or those with high sealing requirements require more complex systems, naturally increasing the price.

Production Capacity: The faster and higher the output of Vertical Form Fill Seal Packing Machines, the more demanding the machine configuration becomes, resulting in a higher price.

Level of Automation: Machines equipped with PLC control, touch interfaces, automatic film alignment, automatic metering, automatic packaging, and automatic sealing are significantly more expensive than semi-automatic or manual machines.

Applicable Bag Types:If the machine needs to support multiple bag types, the design will be more complex, requiring higher standards for the mechanical structure, forming device, and sealing system, thus increasing the price of Vertical Form Fill Seal Packing Machines.

Customization: If customers need to customize according to their own product characteristics, such as non-standard packaging bags, composite films, multi-layer films, high-barrier films, etc., or require the machine to be able to flexibly switch packaging specifications, then the price of customized design will naturally be higher than that of standard machine.

Vertical Form Fill Seal Packing Machines Price depends on the supplier selection.

Machrise offers a cost-effective supplier for Vertical Form Fill Seal Packing Machines. Its products are ISO 9001 certified and CE certified. As a source manufacturer, Vertical Form Fill Seal Packing Machines Price lower than comparable suppliers. Machrise can customize its machines based on customer requirements, including packaging materials (powders, granules, liquids, etc.), bag size, packaging speed, and film material. Machrise typically provides complete packaging and shipping (with wooden crates and steel frames) and delivers the machines to the customer's location by land, sea, or air.

Vertical Form Fill Seal Packing Machines play an important role in various industries. Understanding its structural features such as the forming system, metering device, sealing device, etc. can help evaluate the performance of the equipment. When choosing to buy Vertical Form Fill Seal Packing Machines, the type of material should be considered. Granular materials, powdered materials, liquid materials, etc. have different functional requirements for packaging machines. Granular materials such as rice and beans require vibration or spiral feeding systems; powdered materials such as flour require pneumatic or spiral metering devices; liquid materials require dedicated liquid pumps and sealing technology. Comprehensively evaluate production needs, budgets and material characteristics to select the most suitable packaging solution.