Sieving Methods of Sieve Analysis

Monday July-14 2025 17:52:09

In the fields of particle material production, research and development, and quality control, Analytic Sieve serves as a core method for determining particle size distribution. The selection of equipment directly impacts analysis efficiency and data accuracy. This article provides a concise and practical selection guide for the four common types of sieving equipment: Standard Test Sieves, Ultrasonic Test Sieves, Tapping Sieves, and RoTap Sieves. Whether processing agglomerating fine powders or separating coarse particles, scientific selection can quickly match the optimal sieving solution, facilitating efficient particle size analysis.

What are the common test sieves?

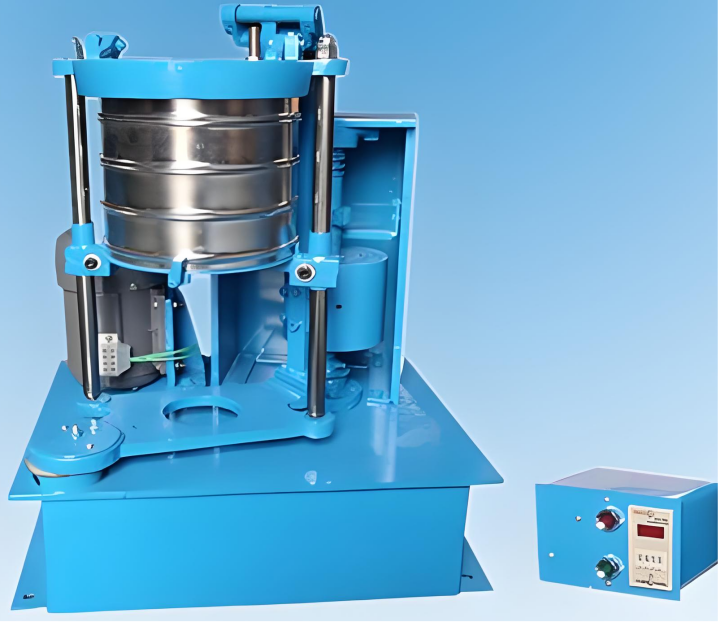

Standard Test Sieve:Standard Test Sieves are suitable for preliminary sieving of conventional materials such as sand, grains, and common chemical granules, covering a range of 10-200 mesh (particle size 1700μm-75μm). Driven by a motor, they generate vibration causing material to move in a spiral motion on the sieve surface for stratification. This equipment features a simple structure, low cost, and easy operation, making it suitable for routine sieving of dry, non-sticky materials. However, its efficiency is low for fine powders (<75μm), sticky, or easily agglomerating materials, and manual screen cleaning is required.

Ultrasonic Test Sieve: Ultrasonic Test Sieves are suitable for ultra-fine powders in the range of 200-500 mesh (75μm-30μm), such as traditional Chinese medicine powder, lithium battery materials, and nanoparticles that are prone to agglomeration or carry static electricity. Their core technology is an additional 0.8-2.4 MHz ultrasonic vibration system. High-frequency sound waves break up particle agglomeration and prevent screen clogging. The sieving pass rate can increase by more than 30%, enabling precise processing of sub-micron materials. They are suitable for laboratories and high-precision testing scenarios.

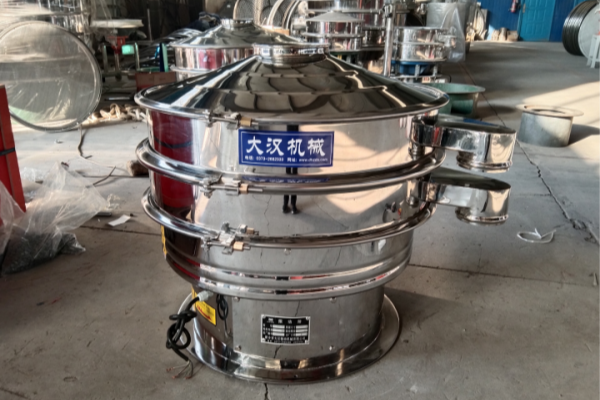

Tapping Sieve: Tapping Sieves are suitable for medium-coarse particles (10-150 mesh, 1700μm-100μm), materials with high moisture content, or those with high friction, such as wet sand, fertilizer granules, and primary ore screening. They feature dual motion characteristics: horizontal reciprocating shaking (amplitude 5-15mm) and bottom tapping (frequency 60-120 times/minute). This accelerates material dispersion, results in fast discharge speed, and prevents screen clogging, making them suitable for industrial batch sieving.

Rotap Sieve:Rotap Sieves are suitable for sieving and grading coarse particles (10-100 mesh, 1700μm-150μm) and high-hardness materials (such as ores, refractory material aggregates). Their top-hammer tapping mechanism periodically impacts the sieve assembly (frequency 80-200 times/minute), combined with horizontal vibration to generate strong vertical impact force. The equipment allows adjusting the tapping force via counterweights to adapt to materials with Mohs hardness levels 3-7. The sieve frame has a large capacity, supporting 10 layers of φ300mm screens, suitable for large-scale production testing. It comes standard with a damping system, controlling noise below 75dB.

How to select equipment based on mesh (sieving accuracy)?

Sieving mesh represents the aperture size of the screen. Higher mesh number means smaller aperture and higher sieving precision.

| Target Mesh | Corresponding Particle Size Range | Recommended Equipment | Core Advantage | Typical Application |

| 10-60 mesh | 1700μm-250μm | Ro-Tap® Sieve / Tapping Sieve | Strong impact force breaks lumps, suitable for coarse particle grading | Ore grade analysis, Construction sand/gravel sieving |

| 60-200 mesh | 250μm-75μm | Standard Test Sieve / Tapping Sieve | Balances efficiency and cost, adapts to medium-fine particles | Chemical raw materials, Food granules (sugar/starch) |

| 200-500 mesh | 75μm-30μm | Ultrasonic Test Sieve | Sonic dispersion prevents clogging, specializes in ultra-fine powders | Lithium battery materials, TCM ultra-fine powder, Pigments |

| >500 mesh | <30μm | Ultrasonic Test Sieve | Paired with electroformed screens for sub-micron sieving | Catalysts, Nano-ceramic powder, Electronic-grade powder |

How to select equipment based on the characteristics of the material?

Material Hardness (Mohs Hardness)

- Soft Materials (≤3, e.g., flour, resin): Choose Standard Test Sieves with 304 stainless steel meshes to prevent rust. Select mesh count based on fineness requirements (e.g., 80–120 mesh for flour).

- Medium-Hard Materials (3–6, e.g., quartz sand, calcium carbonate): Use Tapping Sieves with a tapping frequency of 60–120 taps/minute to balance sieving efficiency and mesh life. Pair with impact-resistant punched plate meshes.

- Hard Materials (6–7, e.g., iron ore, corundum): Opt for Top-Impact Sieves with tungsten carbide-coated meshes. Adjust tapping force to medium-high (100–150 taps/minute) for effective dispersion of large particles.

Material Surface Characteristics

- Sticky/Agglomerate-Prone (e.g., damp Chinese herbal powder, starch paste): Ultrasonic Test Sieves are essential. Activate 100–200W ultrasonic power to break hydrogen bonds, and use hydrophobic meshes (contact angle > 110°) to increase sieving efficiency by 50%.

- Flaky/Acicular Particles (e.g., glass fiber, graphene): Use Tapping Sieves in low-frequency mode (60 taps/minute) with a 15° inclined mesh to reduce particle bridging and improve pass-through rate.

Moisture and Temperature

- Dry Materials (moisture content < 5%): For coarse particles, choose Top-Impact/Tapping Sieves; for fine particles, select Standard/Ultrasonic Test Sieves based on mesh count.

- Wet Materials (5%–20% moisture content): Use Tapping/Top-Impact Sieves with punched meshes (open area ≥ 40%) and an 8° mesh inclination to accelerate discharge and prevent sticking.

- High-Temperature Materials (> 100°C): Select Ultrasonic Test Sieves with 260°C-resistant polyimide meshes and a forced air-cooling system to prevent material caking.

Related parameters of commonly used test screens

Technical Parameters of Lab Vibrating Screen

| No. | Name | Unit | Parameter |

| 1 | Sieve diameter | mm | Φ200 |

| 2 | The quantity of layer | s | 1-7 |

| 3 | Number of revolution | Timed/min | 290±6 |

| 4 | tapping | Timed/min | 1-4 |

| 5 | Tapping height | KN | 38±6 |

| 6 | Levelness of the base | mm/min | ≤0.6 |

| 7 | Motor powder | KW | 0.37 |

| 8 | Powder supply | V | 380,220 |

| 9 | Outside dimension | LWH | 433*432*785 |

| 10 | Rotation distance | mm | 25 |

Technical Parameter of Ultrasonic Sieve Shaker

| No. | Name | Unit | Parameter | ||

| 1 | Test sieve frame | layers | 1-7 | ||

| 2 | Screen frame diameter | mm | φ200、φ300 | ||

| 3 | Sieve particle size | mm | 0.025-3 | ||

| 4 | Noise | db | <50 | ||

| 5 | Feeding amount (one-time) | g | <500 | ||

| 6 | Amplitude | mm | <5 | ||

| 7 | Motor | Voltage | V | 220 | |

| Rotating speed | R/min | 1450 | |||

| Power | KW | 0.18 | |||

| 8 | Dimensions | mm | 350: 350:300+N*50 | ||

In the analysis of particulate material screening, the core of scientific selection is to match material characteristics and equipment performance. The number of mesh determines the accuracy, and the number of mesh mesh needs to be selected according to the particle size; the hardness, surface characteristics, humidity and temperature affect the movement mode of the equipment, the material of the screen and auxiliary functions. Ordinary sieve is suitable for conventional materials. Ultrasonic sieve solves fine powder agglomeration, and sieve hits and sieves target medium-coarse particles and hard materials respectively. Rationally utilize parameters such as slap frequency and ultrasonic power to improve efficiency and accuracy. Differentiated selection based on material characteristics is the key to ensuring efficient and accurate screening, and helping all industries achieve particle size control goals.

Vibro Sifters For Sieving Molybdenum

Vibro Sifters For Sieving Molybdenum Analytic Sieve

Analytic Sieve Sieve Shaker

Sieve Shaker