What Is a Sieve Test

Friday July-11 2025 17:59:13

In the production, research, and quality control of granular materials, a sieve test is a fundamental technique for classifying particles by size using standardized sieves. Its core goal is to accurately obtain particle size distribution data. For industries reliant on granular properties—such as chemicals, pharmaceuticals, and construction—the accuracy of sieve testing directly impacts process optimization and product quality. The key to effective testing lies in two critical components: sieve frame materials and sieve hole types. This article explores these to help you master sieve testing logic and enhance particle classification efficiency in industrial settings.

What Are the Main Sieve Frame Materials?

Sieve frames, as the structural support for sieves, determine equipment suitability, lifespan, and data reliability. Here’s an overview of three mainstream materials:

Stainless Steel Sieve Frames

With high strength, corrosion resistance, and temperature tolerance, stainless steel is ideal for chemical, metallurgical, and ore sieving. Its smooth surface meets hygiene standards for food and pharmaceuticals while withstanding hard particle impacts. Applications include aggregate grading for concrete (ensuring long-term testing stability by avoiding rust-induced aperture deformation) and metal powder screening.Brass Sieve Frames

Brass frames stand out for high-precision machining and non-magnetic properties, making them perfect for laboratory testing and pharmaceutical raw material sieving. Their ductility suits fine powders (e.g., APIs, precious metal powders), preventing metal contamination. A key use is uniformity testing of drug granules, where precise apertures ensure dissolution rates meet standards for reliable pharmaceutical process data.Nylon Sieve Frames

Nylon frames offer lightweight design, chemical resistance, and flexibility, widely used in food, agriculture, and environmental sectors. Non-reactive with organic solvents, they work for non-abrasive materials like flour or soil. Cost-effective and easy to replace, they’re ideal for research labs or small-scale production—e.g., soil analysis, where they prevent metal ion contamination to ensure accurate particle size data.What Are the Key Types of Sieve Holes?

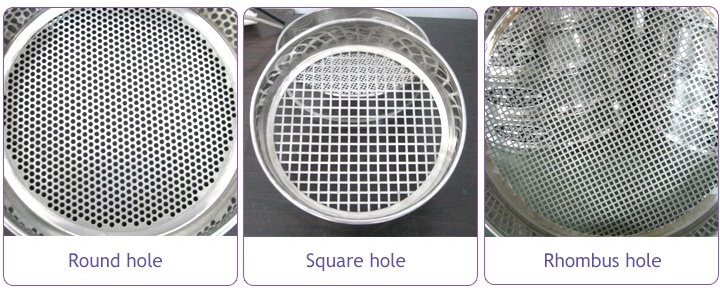

Hole geometry directly affects particle separation efficiency. Here are the main types:

Round Hole Sieves

The most classic design, round holes allow passage only if particle diameter is smaller than the aperture. Suitable for spherical/near-spherical particles, they’re used in construction sand sieving (controlling grain size for concrete strength) and mining (preventing oversize particles from damaging grinding equipment). Critical for strict size control scenarios like 3D printing metal powders.Square Hole Sieves

With 20–30% larger open area than round holes, square holes enable fast sieving of fine particles. In food processing, they efficiently separate sugar/starch powders to boost production speed; in cement manufacturing, they quickly filter particles meeting strength standards. A balanced choice for high-throughput, cost-effective sieving (e.g., fertilizer grading).Rhombus Hole Sieves

Asymmetric rhombus holes accommodate elongated/flat particles (e.g., mineral fibers, wood chips) by allowing alignment along the hole’s long axis. Used in composite material production (screening fiber lengths for product strength) and environmental applications (removing fibrous wastewater impurities). Essential for industries where particle shape matters, like paper and textiles.Every detail of sieve testing—from frame material corrosion resistance to hole type shape adaptability—links to industrial efficiency, cost, and quality. Matching materials and hole types to your specific granular properties maximizes testing value, whether for heavy industry or precision pharmaceuticals. As the “gold standard” of particle classification, sieve testing is a starting point for process optimization. Contact us for customized solutions or sieve selection guides tailored to your industry needs.