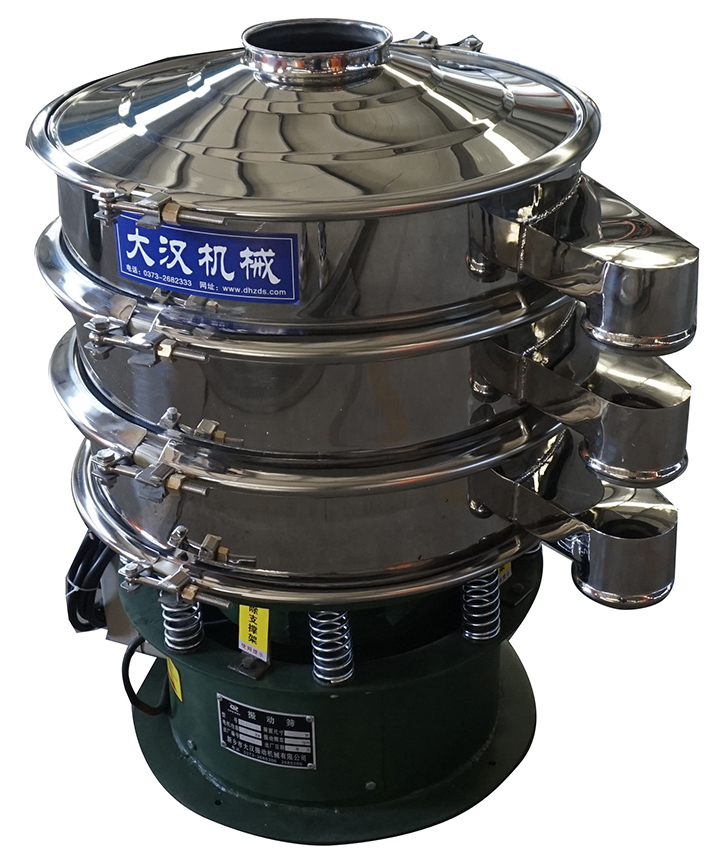

Test Sieve

Test Sieve is priced between$20 to $800/Set. It delivers precise particle size analysis, making it ideal for laboratory testing, industrial quality control, and material classification—reliable, cost-effective, and tailored to diverse screening needs.

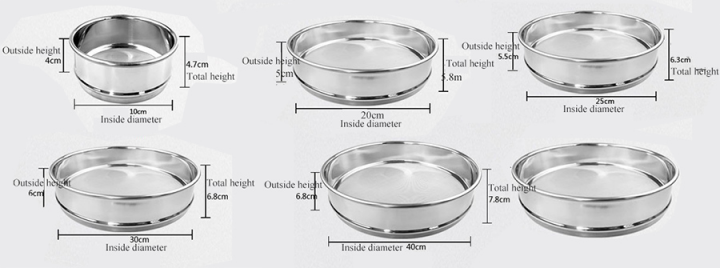

Diameter:500/400/300/200/120/80/75mm,or others as your requirements.

Aperture sizes:0.02-2.36mm

Surface type:Woven Wire Mesh/Perforated Plate/Electroforming Mesh

Hole shape:Square/Round/Diamond

Material:Stainless steel304/Brass/Chromeplate

What is a Test Sieve?

A Test Sieve is a core tool for particle size analysis and classification of granular materials, consisting of two main parts: a sieve frame and a sieve mesh. The frame is typically made of stainless steel or aluminum alloy for strength and durability. The mesh, available in materials like woven wire or electroformed sheets, offers pore sizes ranging from microns to millimeters, adjustable for different screening needs. Through mechanical vibration or manual operation, it separates particles by size as materials move over the mesh. In laboratory testing and industrial classification, test sieves adhere to international standards (e.g., ISO 3310) and national standards (e.g., GB/T 6003), ensuring efficient screening and reliable support for material quality control and process optimization.

In laboratory testing and industrial classification, test sieves adhere to international standards (e.g., ISO 3310) and national standards (e.g., GB/T 6003), ensuring efficient screening and reliable support for material quality control and process optimization.

What are the Classifications of Test Sieves by Hole Shape?

Test sieves are categorized by hole shape into round, square, woven mesh, and diamond holes, each tailored to specific particle characteristics. The hole shape directly affects screening efficiency and applicability, guiding targeted selection.

Round Hole Test Sieves: With circular apertures, they are suitable for screening regular-shaped particles (e.g., metal pellets). Their uniform force distribution reduces particle clogging, ensuring stable screening results.

Square Hole Test Sieves: Featuring square apertures, they are widely used in powder materials (e.g., cement, flour). The larger effective screening area improves efficiency, making them ideal for high-throughput scenarios.

Woven Mesh Test Sieves: Made by weaving metal wires, they have flexible aperture ranges (from microns to millimeters). They are cost-effective and versatile, applicable to both coarse and fine particle screening.

Diamond Hole Test Sieves: With diamond-shaped apertures, they adapt to irregular particles (e.g., mineral fragments). The inclined hole edges reduce particle adhesion, suitable for viscous or flaky materials.

What are the Types of Test Sieves?

Test sieves are divided into dry and wet types based on application scenarios, each with unique structural designs. Dry sieves suit free-flowing dry powders, while wet sieves handle viscous materials with liquids, meeting diverse screening requirements.

| Type | Structural Features | Core Application Scenarios | Differential Advantages |

|---|---|---|---|

| Dry Test Sieve Frame |

- Lightweight design (0.6mm wall thickness) - Single-layer silicone sealing ring - Standard pore size ≥45μm |

Free-flowing dry powders such as cement, mineral powder, and flour |

- Reduces vibration energy consumption - Prevents electrostatic adsorption of fine powders |

| Wet Wash Test Sieve Frame |

- Thickened and reinforced frame (1.0mm wall thickness) - Double-layer waterproof silicone ring - Optional 316L anti-corrosion material - Pore size ≥20μm |

Viscous materials containing liquids, such as clay, biological slurries, and mineral slurries |

- Resists high-pressure water impact (0.3MPa) - Built-in flow guide grooves prevent mesh blockage |

| Dry Classification | Wet Classification | |||

| Size fraction,μm | Wt.,% | Cum. wt.,retained % | Wt.,% | Cum. wt.,retained % |

|---|---|---|---|---|

| +600 | 11.74 | 11.74 | 1.32 | 1.32 |

| -600+106 | 79.76 | 91.50 | 87.28 | 87.28 |

| -106+45 | 2.37 | 93.87 | 2.53 | 91.13 |

| -45+25 | 0.98 | 94.85 | 1.42 | 92.55 |

| -0.025 | 5.15 | 100.00 | 7.45 | 100.00 |

| Total | 100.00 | 100.00 | ||

What are the Advantages of Test Sieves?

Test sieves offer high precision, wide applicability, and compliance with international standards, making them indispensable in material screening. Their durability and efficiency reduce operational costs while ensuring reliable results.

High Precision: Adhering to international standards (e.g., ISO 3310), the aperture error is minimal, ensuring accurate particle size classification.

Strong Adaptability: From dry powders to viscous slurries, and from coarse to fine particles, they meet diverse screening needs across industries.

Cost-Effective: Woven mesh sieves, in particular, balance performance and price, suitable for large-scale industrial applications.

Durable: Made of stainless steel or corrosion-resistant materials, they withstand long-term vibration and chemical erosion, extending service life.

Technical parameters of test Sieve

| Items | Name | Unit | Data |

|---|---|---|---|

| 1 | Layers | layer | 1-8 |

| 2 | Diameter | mm | 200, 300 |

| 3 | Sieve frame | mm | 100, 200, 300, 400 |

| 4 | Noise | db | below 50 |

| 5 | Feeding Capacity (Once) | g | <200 g/ml |

| 6 | Amplitude | mm | <5 |

| 7 | Voltage | v | 220 v / customized |

| 8 | Power | kw | 0.125 |

| 9 | Overall Dimension | mm | 450*410*700 |

| 10 | Weight | kg | 60 |

Test sieve mesh size

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

|---|---|---|---|---|---|

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

What is the Role of Test Sieves?

Precise Classification: With standardized sieve mesh apertures, test sieves ensure strict separation of particles by size, keeping the error within the range of international standards.

Data Support: They provide particle size distribution data for production process optimization, helping to adjust production parameters and improve product quality.

Efficiency Improvement: Combined with standardized sieve frames, mechanical screening increases efficiency by more than 10 times compared with manual screening.

Compliance Assurance: Test sieves that meet international certifications such as ASTM and CE can be directly used for quality inspection of export products, avoiding trade barriers.

What are the Different Types of Sieve Mesh Materials?

| Test sieve pictures |

|

|

|

| Woven mesh test sieve | Perforated plate test sieve | Electroforming test sieve | |

| Test sieve surface |

|

|

|

| diameter | 75mm/200mm/300mm | 200mm/300mm | 75mm |

| Mesh size | 2.36mm-0.038mm | ≥3mm | 500mm-5μm |

| Material | Stainless steel/brass/tin bronze | Red copper | Stainless steel |

| standard | SO3310-2:1990 R20/3、R20、R40/3 | SO3310-2:1990 R20/3、R20、R40/3 | SO3310-2:1990 R20/3、R20、R40/3 |

| Feature | Low cost, wide application range, light weight, durable | The most wear-resistant, suitable for materials with high density, large impact on the screen surface, and irregular shapes | The highest accuracy, used in high-precision laboratory scenarios |

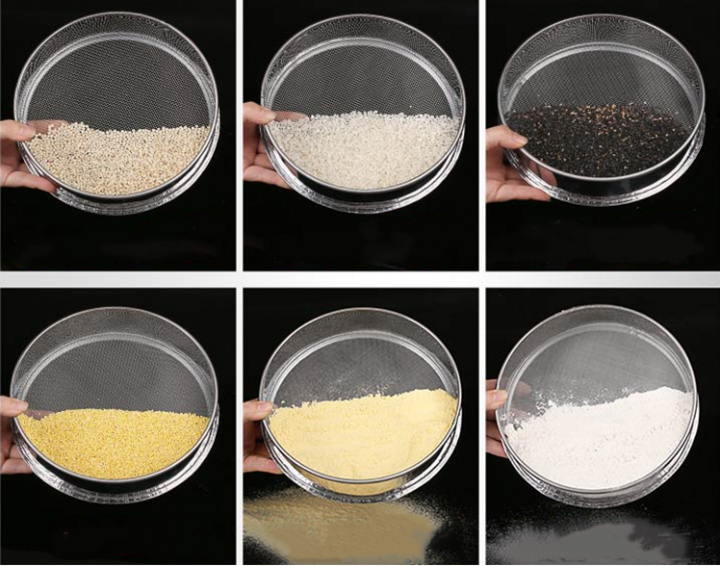

What are the Applications of Test Sieves?

Test sieves play a key role in industrial production, laboratory research, and quality control, bridging material standards and practical needs. They ensure materials meet specifications, supporting production optimization and scientific innovation.

Industrial Production: In industries such as ore processing, chemical engineering, and food production, test sieves are used for raw material inspection and finished product classification, ensuring that the particle size of materials meets production standards.

Laboratory Testing: In universities, research institutions, and quality inspection laboratories, test sieves are employed for particle size analysis of samples, providing data support for scientific research and quality control.

Quality Control: Test sieves are used to check whether raw materials or finished products meet the specified particle size standards. For example, pharmaceutical particles need to pass the inspection of pharmacopoeia sieves to ensure product quality.

New Material R & D: Test sieves assist in the research on the particle size characteristics and process optimization of new materials, such as nanomaterials and new energy materials.

As a key tool in material screening, test sieves are crucial. Whether for strict industrial quality control or precise laboratory research, the right test sieve boosts screening efficiency. Our factory focuses on developing and manufacturing test sieves, using high - standard techniques to ensure frame and mesh precision and durability. We offer a wide range, from dry and wet sieves to standard and customized models, with professional solutions. Leveraging our industry experience and technical know - how, we provide reliable test sieves to help you screen materials accurately and efficiently.