Round Vibrating Sifter

Round Vibrating Sifters range in price from$600 to $4,000/Set. There are various models available, typically classified by sieve mesh sizes (such as 2-80 mesh, 60-300 mesh, 250-500 mesh) and processing capacity.

Price$600.00 - $4,000.00

Layer: 1-5layers

Mesh size: 2-500 mesh

Capacity: 100-3000kg/h

Material:Stainless steel 304,316L,or Carbon Steel

What Is a Round Vibrating Sifter?

Round Vibrating Sifter is a high-efficiency screening device, specially designed for precise particle size separation and classification of powders, granules and viscous materials. Its key feature is a cylindrical stainless steel or carbon steel body paired with an eccentric vibration drive system, generating circular vibrations for uniform material screening. Unlike linear vibrating screens, its 360° circular vibration trajectory enhances material flow and reduces screen clogging. Suitable for 20-500 mesh (850μm-30μm) screening, it is widely used in food, chemical, mining and other industries.

What Are the Types of Round Vibrating Sifters?

Round vibrating sifters have diverse types to meet specific application needs. These variations are tailored to material properties—whether dry powders, viscous mixtures, or ultra-fine particles—and adapt to varying throughput and precision requirements, ensuring optimal performance across industries

Circular Vibratory Sifter:Basic type with classic circular vibration trajectory. Ideal for general powder/granule screening, balancing efficiency and cost-effectiveness in routine industrial use.

Ultrasonic Vibrating Screen:Equipped with ultrasonic system to tackle fine, adhesive materials. Emits high-frequency waves to prevent mesh blinding, ensuring stable sieving of micro-powders (down to 20μm).

Direct Discharge Sifter:Optimized for high-throughput, single-stage screening. Simplified structure for quick material discharge, commonly used in bulk material preliminary filtration.

Filter Screen:Specialized for liquid-solid separation. Fine mesh with reinforced structure handles viscous fluids, widely applied in beverage, chemical slurry filtration.

High Frequency Vibrating Screen:Utilizes high-frequency, low-amplitude vibration. Enhances separation precision for ultra-fine particles (≤30μm), critical in pharmaceutical, advanced material industries.

What Are the Key Features of Round Vibrating Sifters?

Round vibrating sifters stand out with unique design and performance advantages, making them versatile across industries. Their features balance efficiency, adaptability, and operational convenience to handle diverse material screening needs.

360° Circular Vibration:Full-circle vibration ensures even material distribution across the screen, boosting flow speed and reducing clogging—ideal for tricky materials like sticky powders or high-moisture granules.

Broad Material Adaptability:Handles 20-500 mesh materials (powders, granules, viscous mixtures). Adjustable vibration intensity (via counterweights) suits fragile or abrasive substances.

Modular & Sanitary Build:Quick-clamp, stackable screens enable easy layer changes for multi-grade sorting. Stainless steel construction meets FDA/GMP standards, fitting food/pharma use.

Energy-Saving & Low Upkeep:Uses 15-20% less energy than linear screens. Sealed components reduce wear, and detachable parts simplify cleaning.

Scalable Performance:Optional upgrades (ultrasonic systems, frequency converters) extend capabilities—e.g., handling 20μm micro-powders or adapting to material changes in real time.

Parameter

| Model | Diameter (mm) | Feeding Size (mm) | Frequency (RPM) | Layers | Power (kw) | Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

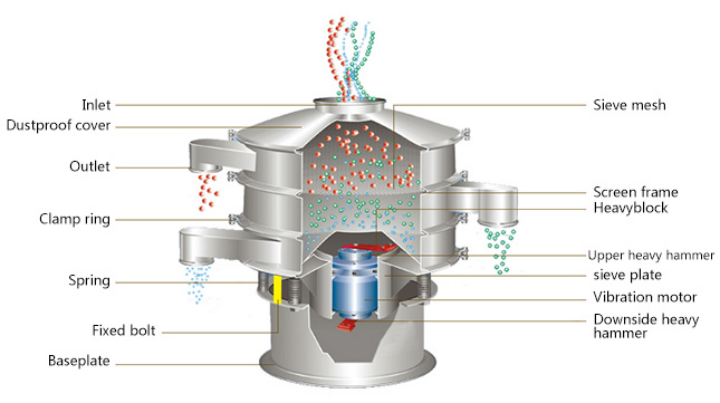

What is the Structure of Round Vibrating Sifter?

Its structure integrates vibration technology and modular design, consisting of a screen body, drive system, dust-proof components, and support mechanism to ensure reliable screening and operational convenience.

Cylindrical Screen Body: Composed of stackable stainless steel or carbon steel screen frames. Different screen layers use corresponding materials to accommodate coarse/fine materials. Quick-clamp rings facilitate disassembly and sealing.

Vibration Drive System: Eccentric vibration motor with adjustable counterweights generates circular vibration. Frequency conversion devices can be optionally equipped to adapt to different material characteristics.

Dust-proof & Sanitary Design: Sealing gaskets and anti-static coatings prevent dust leakage. Mirror-polished surfaces meet sanitary standards. Detachable components enable easy cleaning.

Support & Adjustment Mechanism: Spring-supported base absorbs vibration. Adjustable feet ensure equipment stability. Customizable inlet/outlet chutes adapt to automated production lines.

How Does a Round Vibrating Sifter Work?

The equipment drives material movement through circular vibration, achieving particle separation via multi-stage sieving mechanisms, complemented by anti-clogging designs to enhance efficiency.

Vibration-driven Material Movement: Eccentric motor rotation forms a spiral trajectory of materials on the screen surface. Fine particles pass through the mesh while coarse particles discharge along the periphery.

Multi-stage Classification: Materials undergo layer-by-layer sieving from top to bottom, with each screen retaining corresponding particle sizes until precise classification is completed.

Anti-clogging Solutions: Optional ultrasonic systems or rubber ball cleaners prevent adhesive materials from blinding screens.

Intelligent Control: PLC controller monitors vibration parameters and sieving time in real-time. Touchscreen supports operation and data logging.

Where Is a Round Vibrating Sifter Applied?

With its multi-functional design, the equipment serves critical roles in quality control and production across industries for material screening, classification, and filtration. It adapts to diverse material states—from dry powders and granular solids to viscous slurries—making it indispensable in both precision testing and large-scale manufacturing.

Food & Beverage: Sieving and classification of flour, sugar, spices; pulp separation and suspension filtration.Chemicals & Plastics: Suitable for catalysts, pigments, plastic pellets; supports chemical synthesis and material processing.

Mining & Metallurgy: Particle size classification of mineral powders, metal abrasives, and refractory materials; assists ore processing.

Pharmaceutical Industry: Sieving active pharmaceutical ingredients (APIs) and excipients to ensure material uniformity and meet GMP standards.

Coatings & Inks: Filtering pigments and fillers; eliminating agglomerates to guarantee coating quality and application performance.

As a core equipment for particle size processing, the round vibrating sifter combines mechanical simplicity with high-performance sieving. Through adaptive design and automation integration, it consistently delivers precise sieving solutions for industrial production and scientific research.