Powder vacuum weighing system

Powder vacuum weighing system is an intelligent device that integrates vacuum conveying and high-precision weighing technology. It realizes automatic metering, conveying and batching of powder materials through negative pressure pneumatic conveying combined with weighing sensors.

Material: Stainless steel

Output (kg/h): 1 - 1000 kg/h/customizable

Production rate: 1.3ton/hour

Power (kw): 85

Material shape: Acinose, powder

Applicable materials: API, sterile powder, milk powder, additives, lithium battery materials, photovoltaic powder

What is Powder vacuum weighing system

Powder vacuum weighing system is an integrated equipment designed for accurate metering and conveying of powder materials. It uses a vacuum generating unit to generate negative pressure, and conveys the powder from the storage bin to the weighing device in a closed manner, effectively avoiding dust leakage and cross contamination. The weighing unit uses high-precision sensors and dynamic/static weighing platforms. The system uses PLC intelligent control to link and adjust the vacuum degree, feeding speed and conveying rhythm, and supports multi-formula storage and data traceability.

Advantages of Powder vacuum weighing system

Integrated vacuum conveying and weighing technology, significantly improves the proportioning accuracy and production efficiency, eliminates cross contamination, and helps enterprises upgrade to intelligence.

High measurement accuracy: It can reach one thousandth of the proportioning accuracy, ensuring the accuracy of the customer's formula.

Convenient and intuitive operation: Multiple formula weight values can be flexibly set, and the operation is simple and easy to understand.

Free material ratio: It can achieve the ratio of up to ten or more materials.

Efficient feeding and weighing: The feeding and weighing process is continuous, non-stop, and efficient.

Clean on-site environment: The whole process is a closed structure, and the dust is automatically collected by the dust removal system, without dust leakage and cross contamination, in line with GMP standards and CIP requirements.

Flexible formula storage: Each group of material formulas can be pre-entered, and multiple types of formulas can be stored.

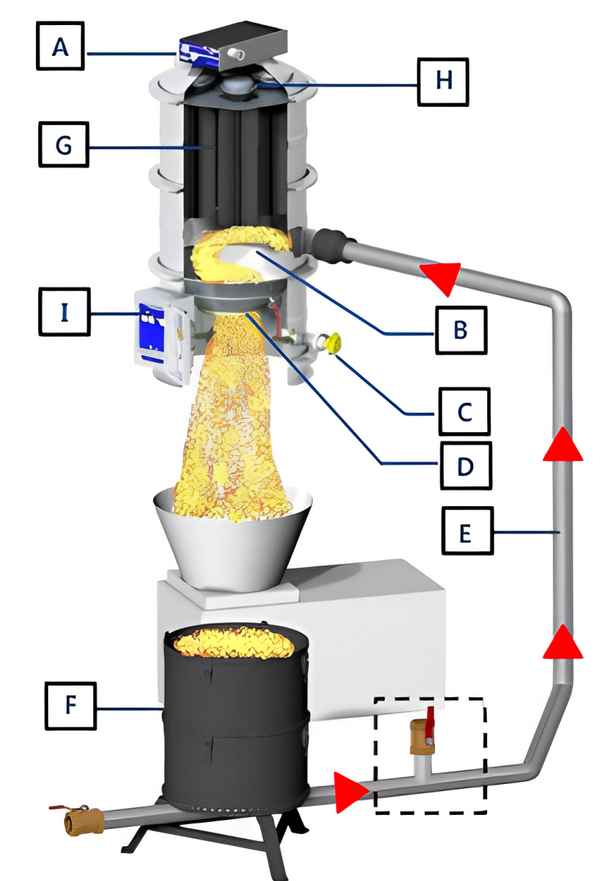

Main structure of Powder vacuum weighing system

It includes vacuum pump/blower, sealed hopper, weighing sensor, pneumatic valve and PLC control module, and realizes the fully automated process of suction-metering-unloading through closed pipelines.

Vacuum generating unit: Its power source is diverse, including Roots vacuum pump, water ring vacuum pump and compressed air-driven ejector, made of 316L stainless steel or food-grade engineering plastics. This design greatly reduces the adhesion and residue of materials in the pipeline.

Weighing and metering unit: There are various weighing platforms, including hopper scales, belt scales or loss-in-weight scales, which can meet the needs of dynamic continuous weighing with a flow range of 0.1 - 50t/h, and can also realize static batch weighing with a minimum division value of 0.1g, which can flexibly adapt to different production scenarios and precision requirements.

Control system: It is the intelligent center of the powder vacuum weighing system, which is composed of PLC intelligent module and human-machine interface. PLC intelligent module can collect weight signals in real time, and control vacuum degree, feeding amount and conveying speed in linkage, so as to realize accurate coordination of each link.

Principle of Powder vacuum weighing system

In the powder vacuum weighing system, vacuum conveying and weighing work together: in the suction stage, the vacuum pump starts to generate negative pressure, sucking the material from the feed port into the pipeline, and then sending it to the weighing hopper after separation by the high-efficiency filter; in the weighing stage, the sensor monitors the weight of the hopper in real time. When the preset value is reached, the PLC controls the pneumatic valve to close the feed port to accurately control the amount of material; in the unloading stage, the vacuum system is closed, and the material is conveyed to downstream equipment such as mixers and packaging machines by means of positive pressure backflush or gravity, realizing seamless connection and efficient coordination between material conveying and weighing.

In what powder scenarios can the weighing system be used?

The system can achieve high-precision measurement and automatic conveying from trace to tons in scenarios such as pharmaceutical precision batching, standardized food production, preparation of new energy materials, laboratory research and development, and scientific feed formulation.

Precision batching in the pharmaceutical industry: Focusing on the ratio of APIs and excipients, aseptic powder packaging and preparation of drugs for clinical trials, the powder vacuum weighing system strictly complies with GMP specifications and controls the feeding error within 1%.

Standardized production in the food industry: In scenarios such as the addition of nutrients to infant formula and the preparation of compound seasonings, the system builds a fully automatic "weighing-mixing-packaging" production line to avoid cross-contamination of allergens through isolation and metering technology.

Precision preparation of new energy materials: For core materials such as lithium battery positive and negative electrode materials and photovoltaic silver paste, the system uses 316L stainless steel with PVDF lining to prevent metal contamination, and ensures material stability through moisture control technology with a dew point of ≤-40℃

Laboratory R&D innovation: Provides key support for new drug development, nanomaterial research, etc. The system has a minimum 5mg micro-metering capability and is equipped with a transparent observation window to achieve real-time monitoring of the experimental process.

Scientific formulation of veterinary drugs/feed: Effectively solve the problem of manual batching accuracy and accurately control the amount of trace elements and antibiotic components added to premixes.

Core parameter selection guide

|

Parameter Type |

Pharmaceutical Sterile Powder |

Food Additives |

Lithium Battery Materials |

|

Vacuum Degree |

-0.06MPa approx. |

-0.04MPa |

-0.08MPa |

|

Weighing Accuracy |

±0.1% |

±0.5% |

±0.2% |

|

Material |

316L stainless steel (electro-polished mirror finish, Ra≤0.8μm) |

304 stainless steel + food-grade coating |

316L stainless steel + anti-static treatment, PVDF lining |

|

Application Advantages |

Complies with GMP, metal ion precipitation <0.1ppm, prevents material contamination |

Meets food hygiene standards, avoids raw material chemical reactions |

Anti-static, anti-metal contamination, compatible with nitrogen protection |

|

Core Function |

Ensures precise drug ingredients, guarantees efficacy and safety |

Controls packaging weight deviation, balances efficiency and cost |

Ensures accurate material ratio, improves battery performance |

Which equipment can be used in combination with the powder vacuum weighing system

It can seamlessly connect with three-dimensional mixers, packaging machines and other equipment, and realize the automation of the whole process of "screening - metering - mixing - packaging" through hose flanges / weighing modules.

Precise batching of mixing equipment: It can seamlessly connect with double cone mixers, three-dimensional motion mixers and other equipment, and realize multi-component automatic batching through pneumatic butterfly valves.

Packaging machine: Used in conjunction with valve bag packaging machines and bottling lines to achieve accurate packaging of 25kg/bag or 5g/bottle. Integrated weight feedback function, automatic calibration of packaging parameters and rejection of unqualified products.

Dust-free feeding and screening: Combined with dust-free feeding stations and vibrating screening machines, a closed-loop process of "feeding-screening-weighing" is formed, which is closed and dust-free throughout the process.

Powder vacuum weighing system price

The price of the powder vacuum weighing system is affected by multiple factors, mainly depending on the system configuration, accuracy level and customization requirements. Basic systems are usually suitable for low- and medium-precision metering of conventional materials, while high-precision pharmaceutical-grade or explosion-proof systems are relatively expensive due to the use of special materials and certified components. System capacity, weighing module accuracy, degree of automation, and industry-specific requirements will significantly affect the overall investment. Compared with manual weighing, although the initial investment is higher, it has the advantages of saving manpower, reducing material loss, and improving product consistency. We provide free technical evaluation to help customers develop the most cost-effective personalized solution.

The powder vacuum weighing system has broken through the limitations of traditional weighing equipment in terms of accuracy, cleanliness, and automation through the integrated innovation of "transport + metering", especially in the field of high value-added powder material processing, showing irreplaceable advantages.