Automatic Packing Machine With Weighing Price

Thursday November-27 2025 17:01:34

Automatic Packing Machine With Weighing Price capabilities varies depending on their specifications and functions. Entry-level models range from approximately $5,000 to $15,000, while high-end, complex models cost around $30,000 or more. Their structure consists of an automatic feeding system, high-precision weighing sensors, an intelligent control system, an adjustable filling mechanism, and a sealing mechanism. They automatically weigh the materials to be packaged, ensuring consistent weight for each batch.

The machine is suitable for packaging materials such as rice, salt, and peanuts. The bag-type model is VFFS-320, and the multi-functional combination model is CY-14+VFFS-420. Since the components configured for different models are different, for example, the bag-type model needs to consider the material and type of the bag, while the combination model needs to include a weighing system and a feeding system, so the price is also different.

Automatic Packing Machine With Weighing Type

Automatic Packing Machines with Weighing are available in various types, including standard vertical sealing packaging machines, multi-head weighing combination packaging machines, pre-packaged bag packaging machines, and palletizing production lines. Vertical systems, which save space and are easy to operate, are ideal for factories with low production volumes. Multi-head weighing combination types offer a smaller margin of error in bag weight distribution, while pre-packaged bag types save time on bag preparation; simply prepare the materials, start the machine, and the bags will be automatically unloaded and packaged. Palletizing production lines are used in large-scale automated production lines.

Automatic Packing Machine With Weighing Price parameter table

| Parameter Category | Parameter Item | Entry-Level/Vertical Form-Fill-Seal Machine | Multi-Head Weighing Combinational Scale Machine | Pre-Made Bag Packaging Machine | Robotic Case Packing/Palletizing Line |

| Equipment Type | Description | Suitable for free-flowing products like granules, powders, tablets. Simple structure, compact size. | Ideal for irregular, sticky items . High precision and speed. | Used for packaging with pre-made bags. Automates bag feeding, opening, filling, and sealing. | Fully automated line integrating packaging, weighing, case packing, and palletizing. |

| Core Parameters | Weighing Accuracy | ± 0.5 - 2 grams | ± 0.1 - 1gram | ± 0.2 - 1gram | Depends on the upstream weighing unit |

| Packaging Speed | 20 - 60 bags/min | 40 - 120 bags/min | 20 - 80 bags/min | 1 - 10 cases/min | |

| Weight Range | 10g - 5kg | 5g - 5kg | 10g - 10kg | 5 - 25 kg/case | |

| Bag/Box Size |

L: 50-300mm W: 40-200mm |

L: 50-300mm W: 40-200mm |

Adapts to pre-made bag sizes | Adapts to standard carton/container sizes | |

| Technical Features | Weighing Method | Volumetric Cup, Screw Feeder, Net Weigh Scale | Multi-Head Computer Combinational Scale | Net Weigh Scale | Integrated platform scale |

| Product Type | Granules, Powders, Liquids, Tablets | Irregular Pieces, Fragile Items, Frozen Food | Granules, Powders, Pieces, Liquids, Pastes | Pre-packaged bags/boxes/bottles | |

| Packaging Material | Roll Film | Roll Film | Pre-made Bags | Cartons, Pallets | |

| Automation Level | Manual Involvement | Manual film reloading, intermittent refilling. | Auto feeding, weighing, bag forming. Manual film reloading. | Auto bag feeding, filling, sealing. Manual empty bag replenishment. | Fully Automatic, only requires material replenishment and fault intervention. |

| Price Range (USD) | Estimated Equipment Price | $5,000 - $10,000 | $10,000 - $50,000+ | $30,000 - $80,000+ | $90,000 - $100,000+ |

| Price Notes | Basic model, single function. | Price increases significantly with the number of weigh heads (e.g., 10, 14). | Price affected by robotic arm complexity and options . | Price highly dependent on robot brand, number of stations, and system integration complexity. |

Automatic Packing Machine with Weighing Process Flow

Materials enter the weighing hopper via a feeding system such as an elevator, screw conveyor, or vibrating feeder. The weighing system automatically dispenses materials in batches according to the set weight, and the materials fall into packaging bags or containers through the drop outlet. During operation, the Automatic Packing Machine with Weighing uses a robotic arm or conveyor belt to position the packaging bags, and a sealing device completes sealing, cutting, or coding. Finished bags are conveyed to a sealing machine or strapping machine for inspection and palletizing. This completes the production line work for one material packaging task.

Automatic Packing Machine With Weighing Price Structure

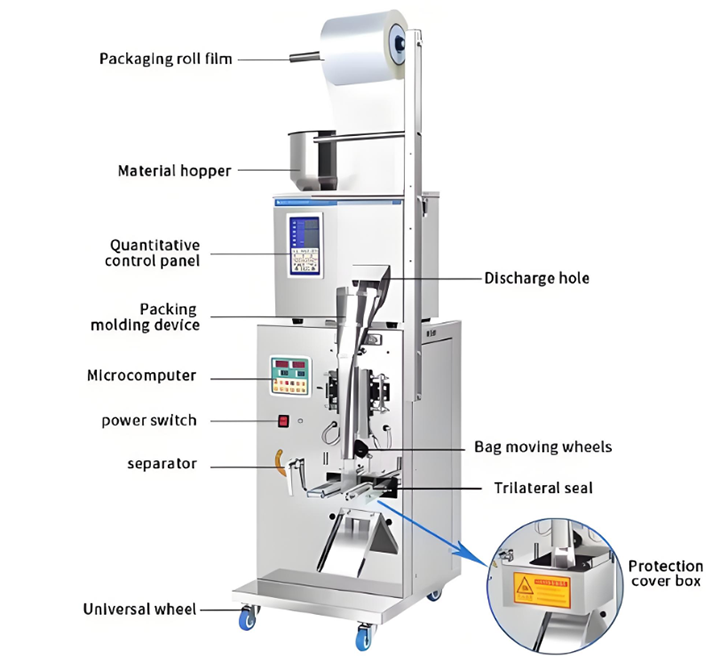

Automatic Packing Machine With Weighing consists of packaging roll film, hopper, quantitative control panel, packaging forming device and other components. These components work together to achieve quantitative packaging and sealing of materials.

The packaging film roll is the raw material for packaging and is processed into packaging bags. The hopper is used to hold the material to be packaged. The quantitative control panel can accurately set the material packaging quantity. The packaging forming device forms the film roll into the shape of the packaging bag. The microcomputer power switch controls the power on and off of the equipment. The separator separates the material from the packaging. The universal wheel facilitates the movement of the equipment. The discharge port is used to discharge the packaged product. The bag moving wheel drives the packaging bag to move. The three-side seal seals the edge of the packaging bag. The protective cover box protects the internal components.

What are the factors that affect the price of Telescopic belt conveyor?

Factors influencing the price of an automatic packaging machine with weighing include the machine's accuracy and speed, degree of automation and functional configuration, machine material, and manufacturing process.

High Precision: The grade and number of load cells used in the machine directly determine weighing accuracy. The higher the accuracy (for example, the difference between ±0.1g and ±1g), the more demanding the sensors and control system are, and the higher the price.

High Speed: The greater the number of products packaged per unit time, the higher the requirements for the mechanical structure (such as the bag clamping mechanism and unloading mechanism), drive system (servo motor vs. stepper motor), and control system, naturally increasing manufacturing costs.

Basic Functions and Extended Functions: Basic machines that only perform weighing and sealing are relatively inexpensive. Adding advanced features such as automatic bagging, vacuum nitrogen filling, date printing, visual inspection, automatic palletizing of finished products, and coordinated control with other production line equipment will increase hardware and software costs for each additional feature.

Material contact part: Depending on the packaging material, the material requirements for the material contact part are also different. For example, dry goods weighing filling packaging machines and liquid weighing packaging machines have different material requirements for equipment. The food and pharmaceutical industries usually require the use of 304 or 316 stainless steel, which is much more expensive than ordinary carbon steel.

Automatic Packing Machine With Weighing Price Manufacturers

Our Automatic Packing Machine with Weighing Price is renowned for its high precision and stability. We customize our equipment based on production output and functionality before production. Our equipment seamlessly integrates feeding, bag clamping, automatic weighing, and seaming. We provide comprehensive user guidance and a professional after-sales team, ensuring comprehensive customer support. This makes us a top choice for many businesses.

Automatic Packing Machine With Weighing is an indispensable and important equipment in modern production lines, with the significant advantages of being fast, accurate, and labor-saving. Different weighing ranges, functional configurations, and applicable material types directly affect its structural complexity and price. For start-ups, small and low-end equipment is a cost-effective choice; while medium and large manufacturers prefer mid-to-high-end equipment with rich functions and high automation. When purchasing, users should comprehensively consider their own product characteristics, packaging volume requirements, and budget range to choose the right model. Overall, the price range of Automatic Packing Machine With Weighing ranges from US$1,000 to US$30,000. The investment payback period depends on the application scenario and output, but it has good economic benefits in the long run.