AS-1000 Fully Automatic Vertical Packaging Machine

Thursday December-11 2025 18:11:44

The AS-1000 Fully Automatic Vertical Packaging Machine enables fully automated packaging of granular, powdered, liquid, and small block products. The machine's overall dimensions are approximately 1800mm (L) x 1100mm (W) x 2200mm (H). Its packaging speed can reach up to 120 bags/minute, with stepless speed adjustment based on product characteristics and packaging requirements. Bag lengths range from 80-200mm, and bag widths from 50-120mm. The AS-1000 is compatible with various common roll films, including polyethylene, polypropylene, metallized film, and composite film.

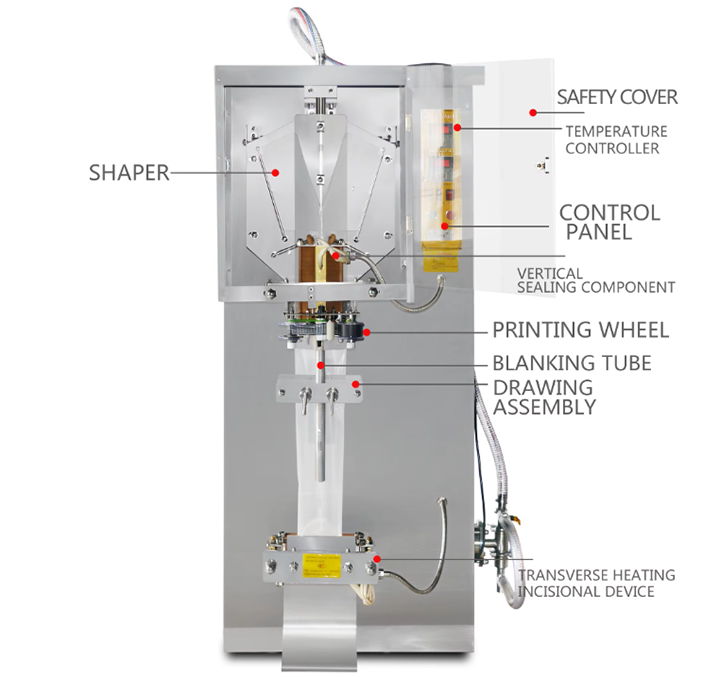

AS-1000 Fully Automatic Vertical Packaging Machine Components

The AS-1000 Fully Automatic Vertical Packaging Machine uses screw metering, measuring cups, or electronic scales to transport products to the bag forming area. The film holder and tension control mechanism support the packaging film roll and maintain constant tension during transport using precision sensors and mechanical devices to prevent wrinkling or breakage. The film is rolled into a cylindrical shape by the tension control and forming device, and then precisely pulled down by servo traction wheels. The longitudinal and transverse sealing devices employ temperature-controlled heat sealing technology to form a strong seal. The inkjet printer clearly prints production dates, batch numbers, and other information in the sealing area. A programmable logic controller (PLC) and color touchscreen enable parameter setting, operation monitoring, fault diagnosis, and data recording, making operation intuitive and simple.

Advantages of the AS-1000 Fully Automatic Vertical Packaging Machine

The AS-1000 Fully Automatic Vertical Packaging Machine boasts a production capacity of 120 bags/minute and a quick film changeover design, reducing unit packaging costs. Its servo drive system and precision mechanical structure ensure high accuracy in bag length, sealing position, and filling volume, resulting in a low scrap rate. A wide size adjustment range and compatibility with multiple metering methods allow for rapid conversion between different products and packaging specifications, making it particularly suitable for flexible production needs involving multiple varieties and small batches. Major structural components are made of high-quality stainless steel and high-strength alloys, and key components such as the sealer and controller are sourced from internationally renowned brands, ensuring a long lifespan and low failure rate under continuous high-intensity operation. The touchscreen interface makes parameter settings clear at a glance and features a memory function to store multiple product formulas, simplifying operation and training.

AS-1000 Fully Automatic Vertical Packaging Machine Specifications

|

Model |

AS-1000 |

|

Capacity |

2000-2200bags/Hour |

|

Volume |

50-550ml |

|

Power |

220v/380v 1.6kw |

|

Film width |

100-320mm |

|

Bag length |

50-150mm |

|

Bag width |

40-150mm |

|

Weight |

275Kg |

|

Package Size |

880*760*1800mm |

AS-1000 Fully Automatic Vertical Packaging Machine Price

The price of the AS-1000 Fully Automatic Vertical Packaging Machine varies depending on the metering method, brand of the coding machine, quantity purchased, and market region. The reference market price range for the standard base model is typically between US$7,000 and US$15,000. For customized solutions requiring special corrosion protection, ultra-high-speed configurations, or complex interconnection systems, the price will be adjusted accordingly.

Suitable Materials for the AS-1000 Fully Automatic Vertical Packaging Machine

The AS-1000 Fully Automatic Vertical Packaging Machine can package granular, powdery, small lump, and both dry and wet products. Examples of products packaged using the AS-1000 Fully Automatic Vertical Packaging Machine include snack nuts, candies, tea, coffee powder, seasonings, potato chips, pet food, dried vegetables, instant drinks, sauce packets, laundry detergent, bath salts, facial mask powder, traditional Chinese medicine slices, granules, herbal tea bags, disinfectant wipes packaging bags, medical dressings, screws, nuts, washers, electronic components, small tools, seeds, and chemical samples.

Case Study of the AS-1000 Fully Automatic Vertical Packaging Machine

A food company introduced the AS-1000 Fully Automatic Vertical Packaging Machine for packaging nuts and candies. Previously, production relied on manual operation, producing only about 1,500 bags per day. After introducing the AS-1000, production efficiency increased to 3,600 bags/day, with packaging weight error controlled within ±0.5%. The machine's user interface is user-friendly, and employees can operate it independently after training. Furthermore, the heat-sealing and cutting results are neat and aesthetically pleasing, leading to positive market feedback and improved brand image and customer satisfaction.

The AS-1000 Fully Automatic Vertical Packaging Machine solves the problems of low efficiency, high dependence on manual labor, inconsistent measurement accuracy, and difficulty in controlling hygiene standards inherent in traditional manual and semi-automatic packaging. It offers fast packaging speed, accurate measurement, high operational stability, and a low failure rate. Simultaneously, it optimizes energy management, reducing energy consumption by approximately 15% compared to similar equipment, achieving energy-efficient production.