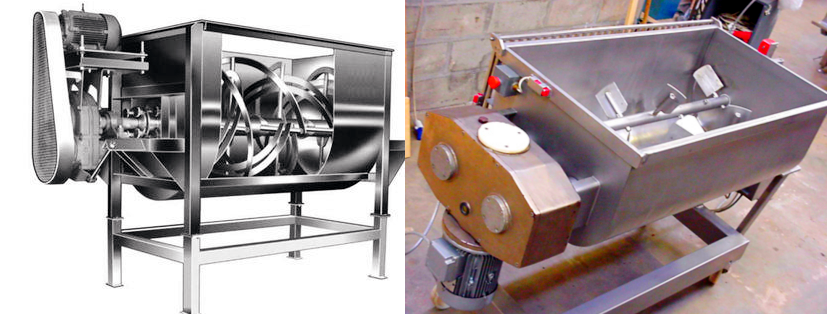

Horizontal Stainless Steel Ribbon Mixer

Horizontal stainless steel ribbon mixer is an efficient and uniform powder and liquid mixing equipment. It achieves uniform mixing of different materials by rotating the spiral ribbon agitator in the horizontal cylinder.

✅High mixing uniformity: up to 99% or more, material residue rate as low as 0.5% or less

✅Short mixing time: generally 5 to 20 minutes

✅Corrosion-resistant material: 304/316 stainless steel, mirror polished

✅High filling factor: usually 60%-80%, high equipment utilization

✅Wide range of application: can mix powders, particles, trace additives, etc.

Product overview

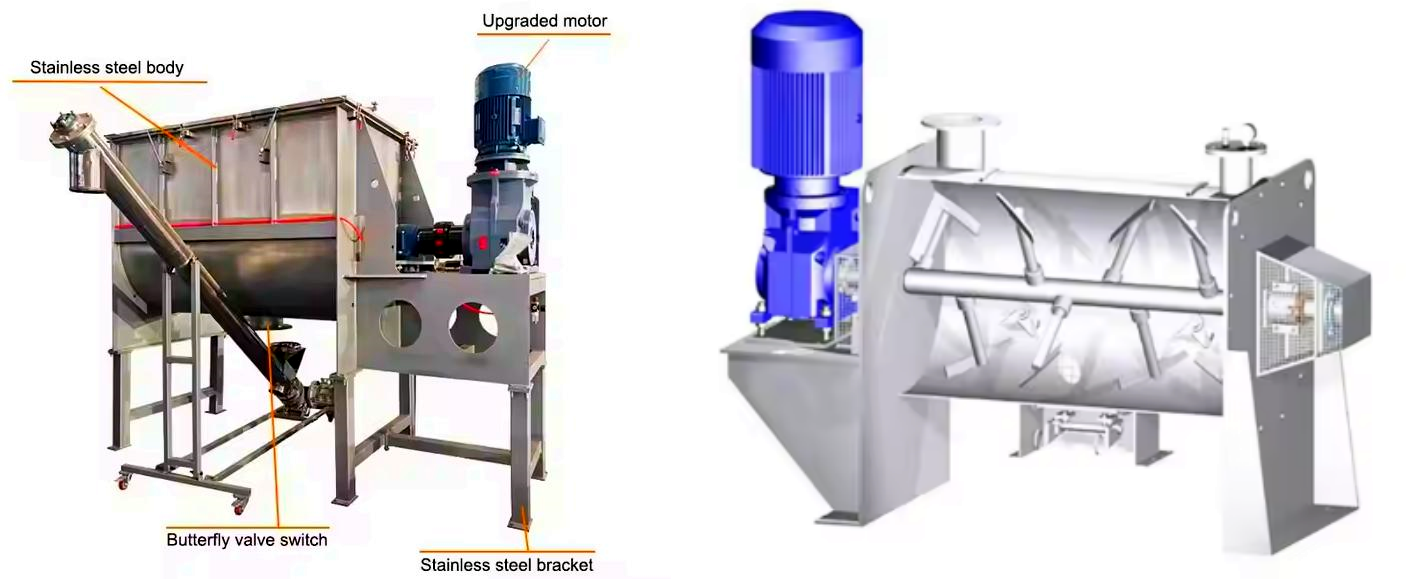

The horizontal stainless steel ribbon mixer is a highly efficient mixing equipment. The main body is a horizontal U-shaped barrel made of 304 or 316L stainless steel. Its core component, the double-layer ribbon mixer, consists of two layers of inner and outer ribbons. The inner ribbon pushes the material from the middle to both ends, and the outer ribbon gathers the material from both ends to the middle, so that the material forms a strong convection circulation in the barrel.

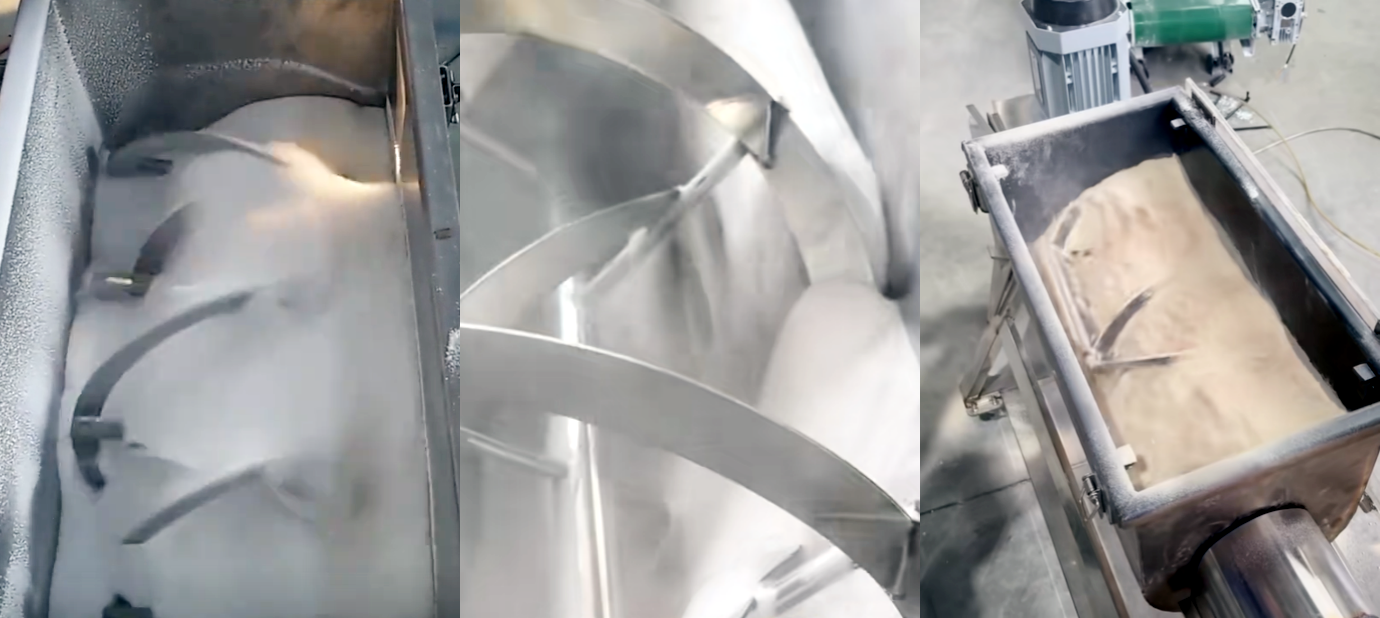

This unique design allows the horizontal stainless steel ribbon mixer to achieve highly uniform mixing of materials in a short time, with a mixing uniformity of more than 99%, which is particularly suitable for mixing powders, particles and a small amount of liquid, such as dry mortar, powder, feed, etc.

What is the difference between a ribbon mixer and a paddle mixer?

Ribbon mixers and paddle mixers are both common horizontal mixing equipment used for uniform mixing of powders, particles, slurries or materials, but there are obvious differences between the two in terms of structural form, mixing method, applicable materials and mixing efficiency.

① Ribbon mixer: It adopts an internal and external double-ribbon structure. The outer ribbon pushes the material to move to the middle, and the inner ribbon pushes the material to move to both ends, forming a composite mixture of axial convection and radial diffusion.

Mixing method and effect: Mixing relies on the ribbon to push the material to flow, squeeze and shear, which is suitable for powders with good fluidity and small specific gravity difference; high uniformity, but sensitive to material adhesion.

Mixing uniformity and time: The mixing speed is fast, and the mixing is generally completed in 5 to 20 minutes, but sticky or easy-to-agglomerate materials may not be mixed evenly.

② Paddle mixer: The agitator is a plurality of paddles with a certain inclination angle, which mix the materials in a throwing manner. The paddles have various shapes and can be customized according to the characteristics of the material (such as oblique blades, cross blades, propellers, etc.).

Mixing method and effect: Mixing is achieved by flipping and throwing materials through paddles. It is suitable for materials with high humidity, high viscosity or large specific gravity difference, such as pastes, wet mortar, etc.; it is less destructive to materials.

Mixing uniformity and time: The mixing time is slightly longer, but the application range is wide, especially in the case of high viscosity materials.

The screw ribbon mixer is suitable for powder materials with good fluidity and high mixing accuracy requirements. The paddle mixer is suitable for mixing occasions with high viscosity, high humidity and large specific gravity difference between particles.

What can the horizontal stainless steel ribbon mixer be used for?

The horizontal stainless steel ribbon mixer is widely used due to its excellent mixing performance and good corrosion resistance. In food processing plants, it can evenly mix raw materials such as flour, sugar, and yeast to produce cake premixes with stable quality; in pharmaceutical workshops, it can accurately mix pharmaceutical powders and additives to ensure uniform pharmaceutical ingredients; in chemical companies, it can fully mix pigments of different colors with solvents to produce coatings with uniform colors and fine textures; in feed factories, it can quickly mix nutrients such as corn flour, soybean meal, and vitamins to make nutritionally balanced animal feed.

In condiment production, it can fully blend condiments such as pepper powder, chili powder, and salt to prepare a compound seasoning with a rich aroma and mellow taste. Whether it is fine food and medicine, or industrial chemical raw materials and agricultural feed, the horizontal stainless steel ribbon mixer can play a role and escort the production quality of various industries.

What are the disadvantages of the horizontal stainless steel ribbon mixer?

Although the horizontal stainless steel ribbon mixer is widely used in many industries, it also has some limitations and disadvantages.

① Not suitable for extremely high viscosity or blocky materials: Although the ribbon mixer is suitable for high viscosity materials (such as putty and sauce), when the material viscosity exceeds the design threshold (such as rubber raw rubber and hard plastic particles), the ribbon may not be able to rotate due to excessive resistance, or even damage the equipment.

② Limited mixing effect on materials with large specific gravity differences: When the particle size or specific gravity difference between the mixed materials is too large, the flow generated by the ribbon stirring may cause light materials to "float" and heavy materials to "sink to the bottom", making it difficult to achieve ideal uniformity and prone to stratification.

③ The structure determines the possibility of mixing dead corners: Especially at both ends of the barrel and near the center axis of the ribbon, there may be areas where the material flows slowly, the so-called "dead corners", which will affect the consistency of mixing, especially in places where high mixing uniformity is required.

④ Not suitable for mixing heat-sensitive materials: During long-term operation, the material may produce local temperature rise under shear and extrusion, which has a potential impact on heat-sensitive powders (such as certain food additives or drug ingredients).

Technical parameters of horizontal stainless steel ribbon mixer

|

Model |

Mixing volume (L) |

Power (kW) |

Production capacity (kg/batch) |

Mixing time (min) |

Dimensions (mm) |

|

LWH-100 |

100 |

4 |

50~80 |

5~15 |

2000×800×1200 |

|

LWH-500 |

500 |

7.5 |

250~400 |

5~20 |

2800×1200×1500 |

|

LWH-1000 |

1000 |

11 |

500~800 |

5~25 |

3500×1500×1800 |

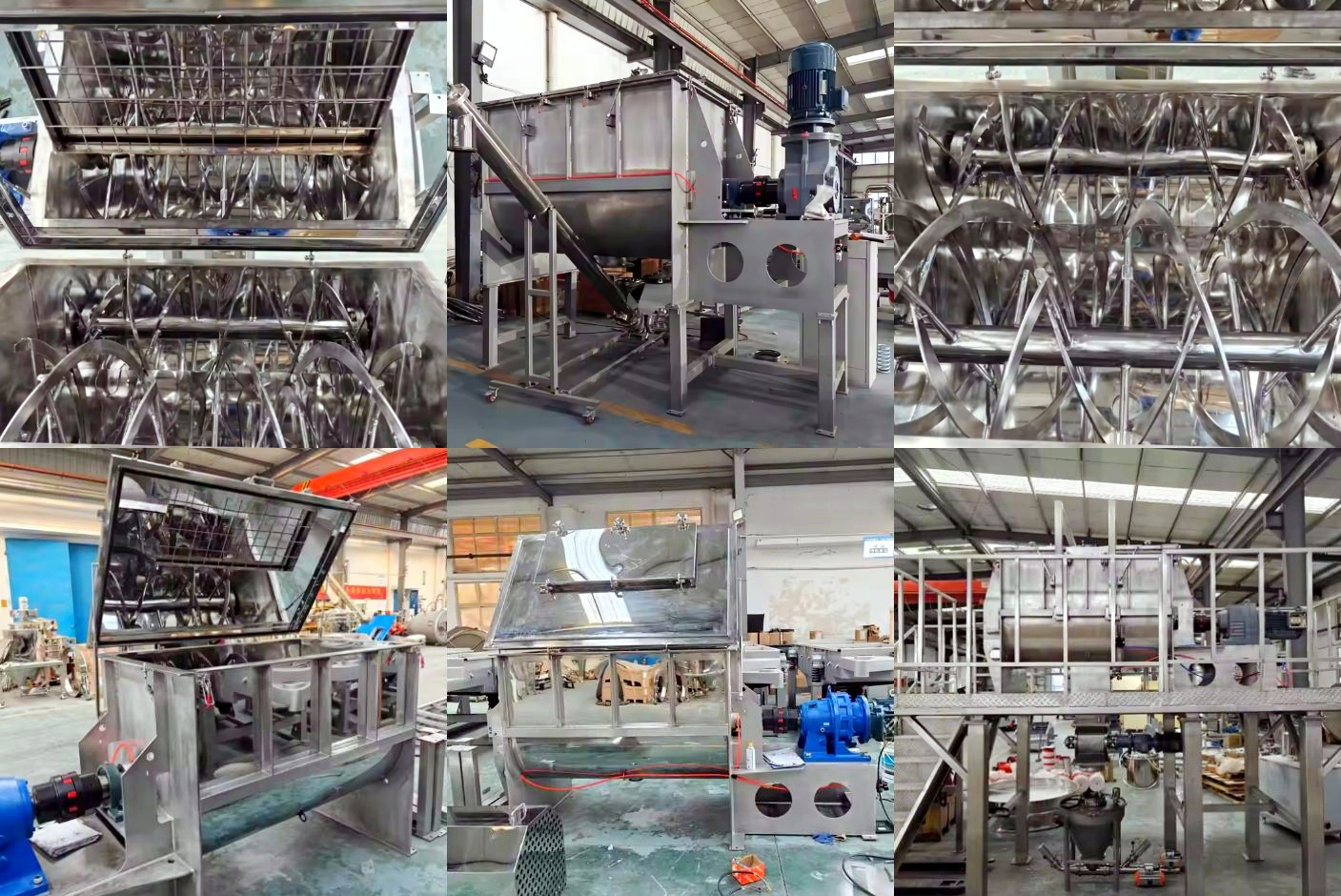

Details of horizontal stainless steel ribbon mixer

Horizontal ribbon mixer usually adopts U-shaped cylinder with double-layer spiral ribbon agitator inside.

The outer layer of spiral ribbon pushes the material from both ends of the cylinder to the center, and the inner layer of spiral ribbon pushes the material from the center to both ends of the cylinder.

The ribbon-paddle combination is to add a dispersing paddle or a crushing paddle to the ribbon to enhance the ability to break up the agglomerated materials.

The inner and outer layers of the ribbon rotate in different directions and speeds to form a convection cycle, so that the materials are fully mixed radially and horizontally in the cylinder. This "figure eight" three-dimensional motion mode ensures that the uniform mixing effect is achieved in a short time.

Related cases of horizontal stainless steel ribbon mixer

A large milk powder production enterprise uses a 2000L horizontal stainless steel ribbon mixer to mix milk powder base materials, vitamins and trace elements. The equipment adopts a double-layer ribbon design. The outer ribbon pushes the material from both sides to the center, and the inner ribbon conveys in the opposite direction to achieve efficient convection mixing, with a uniformity of 99% within 5 minutes.

A paint manufacturer uses a 1000L ribbon mixer to mix pigments, fillers and additives. The high loading factor (0.7) and low energy consumption of the equipment make it suitable for large-scale production, and the uniform mixing is completed within 10 minutes to meet the needs of high-density materials. After adding the spray device, liquid additives can be added accurately to enhance coating performance and reduce production time.

A building materials company uses a 5000L ribbon mixer to produce dry mortar, mixing cement, sand and additives. The equipment is driven by a powerful gear reducer, handles high-density materials without pressure, completes mixing in 8 minutes, and has a uniformity of 97%, effectively improving construction quality.

Horizontal stainless steel ribbon mixer for sale

When choosing a horizontal stainless steel ribbon mixer, factors such as the nature of the material, output requirements, mixing uniformity requirements, equipment material, sealing form, additional functions, and the supplier's reputation and after-sales service need to be considered.

If the production demand is large-scale, high-viscosity, and corrosion-resistant material mixing (such as feed, coatings, and pharmaceutical powders), the advantages of the horizontal stainless steel ribbon mixer are still irreplaceable; but for small batches, low viscosity, frequent batch changes, or high cleaning requirements (such as laboratories, fine chemical small material mixing), vertical ribbons, paddle mixers, or more professional mixing equipment (such as three-dimensional motion mixers) can be considered. The actual selection requires a comprehensive assessment based on material properties, production capacity requirements and budget.