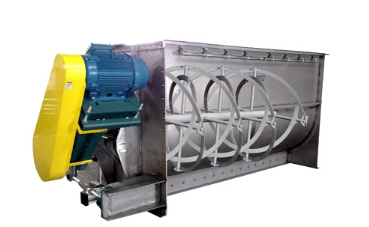

1000L stainless steel ribbon mixer

1000L stainless steel ribbon mixer usually refers to a ribbon mixer with a capacity of 1000 liters and made of stainless steel. It is used to mix materials such as powders, particles, slurries or low-viscosity liquids to achieve a uniform mixing effect.

Effective volume: 1000L

Mixing method: Double-screw horizontal mixing

Mixing speed: 20~40 rpm (customizable)

Mixing time: 5~15 minutes (depending on the fluidity of the material)

Motor power: 5.5~7.5kW (depending on the specific properties of the material)

Application: Applicable to material mixing processes in food, chemical, pharmaceutical, building materials, feed and other industries

Product description

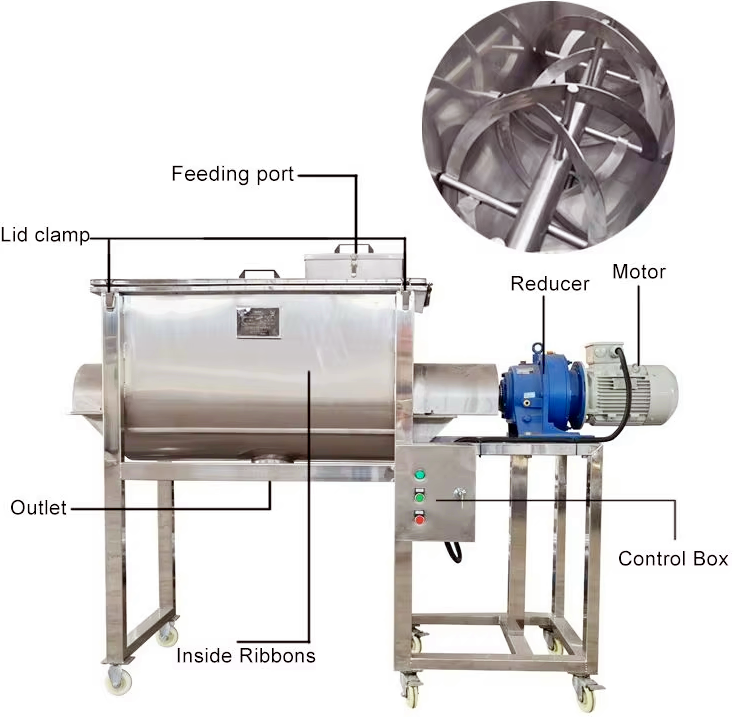

1000L stainless steel ribbon mixer is a horizontal high-efficiency mixing equipment suitable for mixing powders, particles and a small amount of liquid materials. It is mainly composed of a U-shaped barrel, a double-screw agitator and a drive system. The barrel volume is 1000 liters and is made of 304 or 316L stainless steel. It is corrosion-resistant and easy to clean.

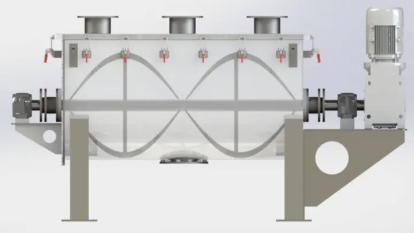

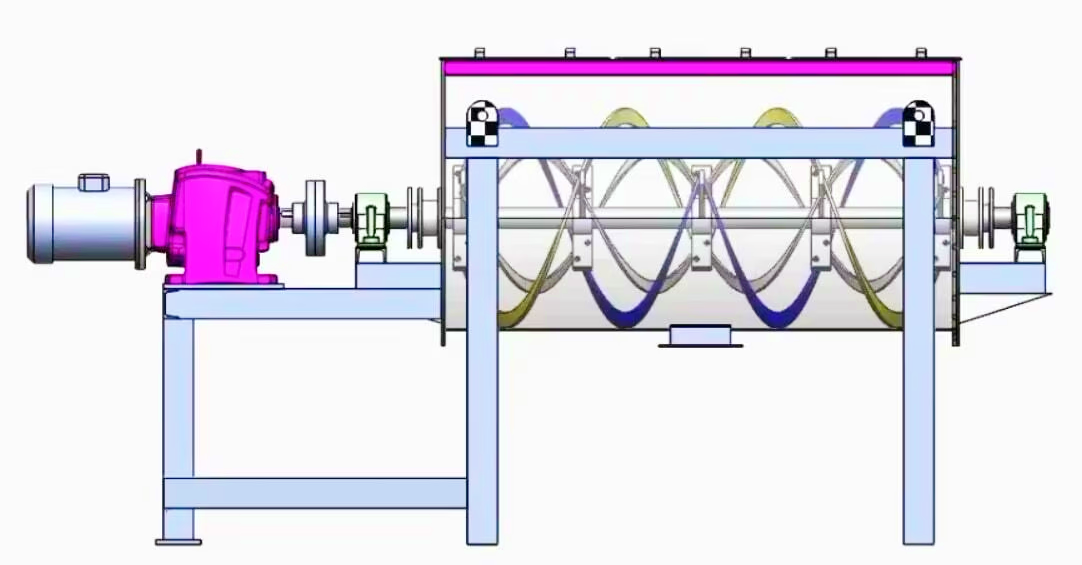

Its core structure is a spiral ribbon that rotates in opposite directions inside and outside. Through the axial and radial compound motion of the spiral ribbon, the material can be mixed with high uniformity in a short time, which is particularly suitable for mixing materials with small viscosity or specific gravity differences. Even powders and particles with large specific gravity differences or poor fluidity can achieve high uniformity mixing effects within 5-15 minutes, avoiding dead corners and stratification.

What are the types of 1000L stainless steel ribbon mixers?

Horizontal spiral ribbon mixer: The U-shaped barrel is placed horizontally, the spiral ribbon is distributed horizontally along the main axis, and the mixing range covers the entire barrel cross-section. The material is pushed by the inner and outer spiral ribbons in both directions to achieve convection mixing. The mixing efficiency is high and the uniformity is good. It is suitable for mixing large-capacity materials and is used in food fillings, chemical powders, feeds and other medium and low viscosity materials.

Vertical spiral ribbon mixer: The barrel is set vertically, and the spiral ribbon is a vertical spiral structure. The material is mixed by circulating up and down. It occupies a small area, but the mixing efficiency is slightly lower than the horizontal type. It is suitable for small production lines or space-constrained scenes. It is used for mixing some chemical raw materials and small amounts of materials in laboratories.

|

Type |

Pocture |

Number of ribbon layers |

Speed range (r/min) |

Motor power (kW) |

Mixing uniformity |

Applicable materials |

|

Horizontal single ribbon mixer |

|

1 layer |

10-30 |

7.5-11 |

≥95% |

Low viscosity liquid, loose powder |

|

Horizontal double ribbon mixer |

|

2 layers |

15-40 |

11-15 |

≥98% |

Medium and high viscosity materials |

Scope of application of 1000L stainless steel ribbon mixer

1000L stainless steel ribbon mixer refers to a horizontal ribbon mixer with an effective volume of 1000 liters, and the barrel and mixing parts are made of stainless steel. It is suitable for material mixing processes in food, chemical, pharmaceutical, building materials, feed and other industries. Its core structure is a horizontal U-shaped cylinder with a double-layer or single-layer spiral ribbon agitator installed inside. The reverse rotation of the inner and outer spiral ribbons pushes and flips the materials to achieve uniform mixing of the materials.

① Powders are mixed with powders (such as flour, milk powder, graphite powder, etc.)

② Powders are mixed with a small amount of liquid

③ Materials that must be avoided from pollution or oxidation (such as food and medicine)

④ Chemical raw materials, feed additives, building materials dry powder mixing, etc.

How does the 1000L stainless steel ribbon mixer work

U-shaped cylinder is used, with a stirring spindle installed inside, and a bidirectional coiled ribbon is installed on the spindle, which is divided into inner and outer spiral ribbons.

Driven by the spiral ribbon, the outer spiral ribbon transports the material to the middle, and the inner spiral ribbon transports the material to the outside, so that the material is repeatedly mixed, thereby achieving fast and efficient mixing.

Features of 1000L stainless steel ribbon mixer

Capacity: 1000L indicates its total volume, and the actual working volume is usually slightly lower than the total volume, such as 400L-800L, depending on the characteristics of the material and the mixing requirements.

Material: The main part in contact with the material is usually made of stainless steel (such as SS304 or SS316), which makes it have excellent corrosion resistance and easy cleaning, especially suitable for industries with high hygiene requirements such as food, medicine, and chemical industry.

Mixing efficiency: The ribbon mixer is known for its efficient mixing ability, and a batch of mixing can usually be completed within 5-15 minutes.

Mixing principle: The internal ribbon mixer is usually designed as a double helix structure, with the inner and outer helices rotating in different directions. The outer helix pushes the material from both ends to the center. The inner helix pushes the material from the center to both ends. This convection mixing effect enables the material to achieve a highly uniform mixing effect in a short time.

Discharging method: There is usually a discharge valve at the bottom, which can be a ball valve, butterfly valve or pneumatic valve, to facilitate the rapid discharge of the mixed material.

Customization: It can be customized according to customer needs, such as adding heating/cooling jackets, vacuum systems, liquid spraying devices, different types of seals (such as packing seals, mechanical seals), and different grades of motors and reducers, etc.

Technical parameters of 1000L stainless steel ribbon mixer

|

Parameter category |

Technical parameters |

Parameter category |

Technical parameters |

|

Model |

WLDH-1000 |

Volume |

1000L |

|

Mixing speed |

20-60 rpm |

Motor power |

7.5-15 kW |

|

Mixing time |

5-20 minutes (depending on material properties) |

Loading factor |

0.6-0.8 (i.e. 600-800L material) |

|

Applicable materials |

powder, paste, high viscosity materials |

Agitator material |

SUS304/SUS316L, blade thickness 6-10mm |

|

Equipment size |

about 2800×1000×1500mm |

Weight |

about 1500-2000kg (depending on configuration) |

|

Power supply |

380V/50Hz |

Applicable industries |

Chemical, pharmaceutical, food, building materials, feed, etc. |

Note: Specific parameters need to be confirmed with the supplier based on material properties (such as viscosity, specific gravity) and process requirements.

What are the application areas of 1000L stainless steel ribbon mixer?

1000L stainless steel ribbon mixer plays a key role in many industries due to its high efficiency, uniform mixing ability and excellent hygienic performance. In the food industry, it is widely used in the mixing of powdered or granular materials such as milk powder, coffee powder, cocoa powder, spices, flour premixes, cereal breakfast and condiments to ensure the flavor and quality consistency between product batches. The pharmaceutical industry relies on it to mix various medicinal powders, Chinese medicine formula granules and health care raw materials to meet product uniformity requirements.

In addition, in the chemical industry, this mixer is an ideal mixing equipment for fine chemical products such as dry mortar, putty powder, coating additives, pigments, dyes, fertilizers and pesticides, which can achieve full integration between different components. The feed industry also often uses it to mix animal feed, premixes and nutritional additives to ensure that animals get balanced nutrition. In the plastics, ceramics and metallurgical industries, it is also often used to mix plastic granules, ceramic powders and metal powders to meet the high requirements of material uniformity in the production process.

1000L Stainless Steel Ribbon Mixer for Sale

The price of 1000L Stainless Steel Ribbon Mixer is usually between $1,000 and $3,099 in US dollars, depending on the model, specifications, configuration (such as power, motor type, whether customized), and production process. Here are some key information:

Small equipment (suitable for small-scale production or laboratory): price is about $1,000 - $1,800.

Medium equipment (medium output): price is about $1,800 - $2,500.

Large equipment (high output): price is about $2,500 - $3,099.

For specific quotes, it is recommended to contact Dahan suppliers for customized options and the latest prices and related parameters