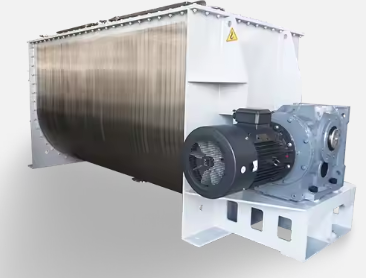

Stainless Steel Animal Feed Mixer

Uniformly mix powdered, granular or a certain proportion of liquid feed raw materials, widely used in agriculture and breeding to ensure that animals get balanced nutritional feed.

Volume: 0.5 cubic meters to 5 cubic meters

Mixing time: 3 to 20 minutes

Mixing uniformity: CV ≤ 5% (some equipment can reach ≤ 3%)

Power configuration: 2.2kW to 15kW

Discharging method: pneumatic gate, manual gate, spiral discharging, etc.

Stirring shaft speed: usually 20 to 60rpm

Product Overview

Stainless steel animal feed mixer is a high-efficiency equipment specially used for mixing various animal feed raw materials, widely used in livestock, poultry, aquaculture and feed processing. Animal feed is usually composed of a variety of powdered, granular or even liquid additives, which require full and uniform mixing in a short time to ensure the nutritional balance and healthy growth of animal feed. Feed is contaminated during the mixing process, especially suitable for the formulation of oils, vitamins and other easily oxidized ingredients.

Stainless steel animal feed mixers have good corrosion resistance and cleaning performance, can effectively prevent raw material contamination and cross residue, and are suitable for use environments with high requirements for feed hygiene. The equipment uses internal spiral ribbon or paddle structure for mechanical mixing, so that different ingredients are fully mixed in a short time, improving the uniformity and palatability of feed, which is beneficial to the healthy growth of animals and the improvement of feed conversion rate.

Classification of stainless steel animal feed mixers

There are many types of stainless steel animal feed mixers, and each type has certain differences in structural design, applicable scenarios, material adaptability and ease of operation. Users can choose the appropriate model according to the scale of feed processing, frequency of use and working environment.

1. Classification by installation method:

① Fixed stainless steel animal feed mixer

Usually installed in the production workshop or batching system, it is suitable for centralized mixing operations in medium and large feed mills or breeding bases. The model has a stable structure and is often equipped with automatic feeders, weighing systems and finished product conveying equipment to form a continuous and automated production process.

Applicable materials: Suitable for mixing various powdered and fine granular feed raw materials such as corn flour, soybean meal, wheat bran, mineral additives, etc.;

Conveying capacity: The common model has a single mixing capacity of 0.5 cubic meters to 5 cubic meters, and the hourly processing capacity can reach 1 to 10 tons;

Mixing speed: The general speed is 20 to 60 rpm, the mixing cycle is 3 to 10 minutes, and the mixing uniformity CV value can be controlled at ≤5%;

②Mobile stainless steel animal feed mixer

The mobile mixer is equipped with rollers or brackets at the bottom, which can be flexibly moved to different operating locations. It is suitable for small and medium-sized farms, temporary processing points or farmers. It has a compact structure, small footprint, and is often equipped with a low-power motor for easy operation.

Applicable materials: Suitable for mixing dry powder and small particle feed, such as compound feed, premix, etc. Some models can also mix a small amount of liquid ingredients;

Conveying capacity: The single mixing capacity is generally 0.3~1 cubic meter, and the hourly processing capacity is about 0.5~3 tons;

Mixing speed: The equipment has low power and moderate mixing speed, which is suitable for intermittent feeding and discharging operations;

2. Classification by structural form:

|

Classification dimension |

paddle mixer |

spiral mixer |

horizontal belt mixer |

vertical mixer |

|

Image |

|

|

|

|

|

Mixing method |

double-axis or single-axis paddle forced convection mixing |

spiral blades promote material axial/radial mixing |

internal and external double spiral belt circulation mixing |

center spiral lifting + natural falling mixing |

|

Conveying capacity |

medium to large (1~10 tons/hour) |

medium (0.5~5 tons/hour) |

medium to large (1~10 tons/hour) |

small~medium (0.3~3 tons/hour) |

|

Mixing speed |

20~60 rpm |

25~80 rpm |

20~60 rpm |

low, generally 10~30 rpm |

|

Mixing uniformity |

high (CV≤5%, some can reach ≤3%) |

medium to high (CV≤5%) |

high (CV≤5%) |

medium (CV about 5~7%) |

|

Applicable materials |

powdered, granular, raw materials containing a small amount of liquid |

dry powder, granular |

powder, granular, small proportion of liquid |

powdered, granular |

|

Discharging method |

pneumatic door, spiral discharging, flap unloading |

manual/electric discharging port |

pneumatic gate/side discharging |

self-weight discharging, some with spiral discharging |

|

Application range |

premix, compound feed, liquid mixing and adding |

small feed processing, independent batching of farms |

feed processing plants, breeding cooperatives |

farmers, small and medium-sized farms |

Applicable materials

Stainless steel animal feed mixer is suitable for processing a variety of granular materials, including: dry materials ( Such as corn kernels, soybean meal, fish meal, bone meal and other concentrates, the particle size is usually between 0.5-5mm); wet feed (such as fermented feed, silage, the moisture content can reach 30%-50%); additives (such as trace particles such as vitamins, minerals, amino acids, etc., which need to be evenly distributed); mixed feed (can handle the mixing of crude fiber materials (such as grass meal) and concentrates to ensure balanced nutrition.)

Difference between 304VS316 stainless steel animal feed mixer

Stainless steel is an ideal material for manufacturing animal feed mixers for the following reasons:

① Strong corrosion resistance: Animal feed may contain moisture, acidic substances or certain chemical components. Stainless steel has excellent corrosion resistance and can maintain the service life of the equipment even in humid or chemical environments.

② Hygienic and easy to clean: The surface of stainless steel is smooth and non-porous, and it is not easy to breed bacteria, mold or residual feed. This is important for maintaining the quality and safety of feed and reducing the risk of cross-contamination.

③ Durable: Stainless steel is known for its strength and durability, and can withstand the wear and tear of daily use and extend the service life of the equipment.

304 stainless steel is the most commonly used food-grade stainless steel, with good corrosion resistance and cost-effectiveness, and can meet most feed mixing needs. 316L stainless steel contains molybdenum and has stronger corrosion resistance. It is suitable for coastal high-salt environments or highly corrosive special feeds (such as some high-salt aquatic feeds), and has a higher cost.

Features of stainless steel animal feed mixer

Mixing efficiency: equipped with propeller blades or planetary mixing structure, uniform mixing, no dead angle, mixing time is usually 3-20 minutes

Versatility: supports both dry and wet use, can handle feed, seed coating, fertilizer and other materials, suitable for family breeding to large-scale breeding farms

High mixing uniformity: multiple mixing methods such as convection, shear, diffusion, etc. are formed during the mixing process, and the mixing uniformity (CV value) can be controlled at ≤5%, and some optimized structures can reach ≤3%

Mixing structure: equipped with propeller blades, planetary or belt mixing devices, no dead angle mixing, suitable for a variety of materials (dry material particle size 0.3-5mm, wet material moisture content 30%-60%)

Technical parameters of stainless steel animal feed mixer

|

Model specification volume (m³) |

mixing amount per batch (kg) |

motor power (kW) |

mixing time (min) |

mixing uniformity (CV%) |

discharging method |

applicable materials |

|

DH-JBJ-300 |

0.3150~200 |

2.2 |

6~10 |

≤5% |

manual gate |

granular feed, powder, premix |

|

DH-JBJ-500 |

0.5250~350 |

3 |

5~8 |

≤5% |

manual/pneumatic gate |

compound feed for pigs, chickens, etc. |

|

DH-JBJ-1000 |

1.0500~700 |

5.5 |

4~6 |

≤5% |

pneumatic gate |

powder, granular, trace liquid |

|

DH-JBJ-2000 |

2.01000~1400 |

7.5 |

4~6 |

≤5% |

pneumatic gate/ Side discharge |

Complete feed for broilers and laying hens |

|

DH-JBJ-3000 |

3.01500~2000 |

11 |

3~5 |

≤5% |

Pneumatic gate |

Oil-containing powder, fine granular feed |

|

DH-JBJ-5000 |

5.02500~3500 |

15 |

3~5 |

≤3% (optimized structure) |

Multi-point discharge |

Large-scale feed production |

What can stainless steel animal feed mixers be used for?

Stainless steel animal feed mixers play a key role in the field of animal feed. In livestock and poultry farming, bulk raw materials such as corn, soybean meal, and bran can be mixed with premixes to make nutritionally balanced complete feed for pigs, cattle, and sheep. Horizontal belt mixers can process 5-20 tons of feed per hour to meet the mass production needs of large farms; in aquaculture, fish meal, fish oil, mineral additives, etc. can be fully mixed to make fish and shrimp feed with high fat content, and the stainless steel material avoids rust pollution to ensure feed quality.

In special breeding, small paddle mixers can accurately mix trace elements, vitamins and other ingredients in pet food and experimental animal feed to ensure accurate nutritional ratio. In addition, for feed containing fibrous materials such as straw and forage, the spiral mixer can achieve simultaneous crushing and mixing with the function of cutting and mixing, improve feed processing efficiency, and provide high-quality and evenly mixed feed for various breeding scenarios.

Related cases

Individual farmers raise about 300 pigs and prepare their own feed, often using raw materials such as corn flour, bran, and soybean meal. 1 0.5 cubic stainless steel vertical mixer with casters at the bottom, which can be moved around the site. The mixing time for each batch is about 8 minutes, which is suitable for small batches and multiple mixing per day; it is convenient to mix on the spot and save manpower and handling costs.

A premix processing workshop is mainly engaged in premix feed processing, which contains a variety of trace additives and has extremely high requirements for mixing accuracy. 1 double-shaft high-efficiency paddle mixer, volume 1.5m³, 304 stainless steel liner, CV value ≤3%. High stirring precision, effectively avoiding uneven distribution of trace components; fast discharging without dead corners, easy cleaning when switching formulas;