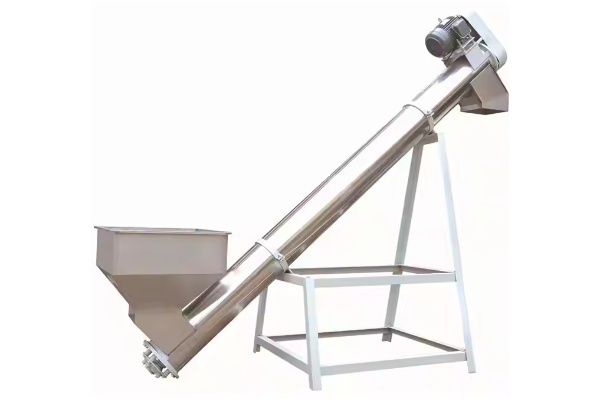

Twin Screw Feeder

The price of Twin Screw Feeder varies greatly due to its model, material, feeding accuracy requirements, drive configuration. Its price ranges from US$400 to US$6,000.

Screw diameter: 100-630mm/customizable

Pitch: 100-580mm/customizable

Speed: 16-140 rpm/customizable

Conveyor capacity: 5-170m3/h/customizable

Material: Carbon steel/stainless steel 304/316L

Power: 22kw

What is a Twin Screw Feeder?

Twin Screw Feeder is a device used in industrial production to continuously and controlled transfer of various bulk materials. This type of equipment is usually divided into carbon steel or stainless steel types according to its material to adapt to the corrosiveness and hygiene requirements of different materials; its screw structure generally adopts a shaft design. In terms of material handling capacity, Twin Screw Feeder can handle materials from several cubic meters to tens of cubic meters per hour, and the conveying or feeding distance of a single device is usually within a few meters.

The selection of Twin Screw Feeder is the key to ensure smooth material handling, which is mainly determined by the material and structure type of the equipment. According to the material classification, the carbon steel Twin Screw Feeder is suitable for handling ordinary non-corrosive materials; there are corrosion-resistant and hygienic stainless steel (such as 304, 316L), which are widely used in the chemical field with requirements for cleanliness; there are also special alloys for extreme working conditions, which are used to handle highly corrosive, high-temperature or high-wear materials. In terms of structure, in addition to the common shafted twin screw, there is also a unique twin shaftless screw feeder. The latter can effectively solve the entanglement and blockage problems of long fibers, sticky or bulk materials because it has no center shaft, and is particularly suitable for the processing of complex materials.

What are the types of Twin Screw Feeder?

Twin Screw Feeder is a commonly used bulk material quantitative feeding equipment. Its unique twin screw structure enables it to perform well in conveying materials with poor fluidity, easy bridging, sticky or fibrous materials. According to different classification standards, Twin Screw Feeder can have many types. The following are its common types:

Carbon Steel Twin Screw Feeder

Features: The body and screw are mainly made of carbon steel.

Applicability: It is usually used to convey non-corrosive materials that do not require high hygiene and are not very abrasive. For example, in some basic industries, ordinary industrial powders, coal powder, or some non-food grade granular materials are conveyed. Its advantage is that the cost is relatively low.

Stainless steel Twin Screw Feeder

Features: The parts in contact with the material (including the screw and the inner wall of the trough/casing) are mainly made of stainless steel (such as 304, 316L, etc.).

Applicability: This is the standard configuration in industries such as food and fine chemicals. Stainless steel has excellent corrosion resistance and can resist erosion by various media such as acids, alkalis, and salts. At the same time, its surface is smooth, easy to clean and disinfect, meeting strict hygiene standards, and preventing material contamination and bacterial growth.

Special alloy Twin Screw Feeder

Features: The screw or liner may be made of wear-resistant alloys (such as high-chromium cast iron, high-nickel alloy) or other special materials.

Applicability: Designed for conveying highly abrasive materials (such as certain mineral powders, abrasives) or operating in extremely corrosive environments to extend the service life of the equipment.

Shaftless Twin Screw Feeder

Features: The twin shaftless screw feeder combines the advantages of twin screw and shaftless design. It has no center shaft, which effectively avoids the entanglement and blockage of long fibers, sticky or bulk materials, ensuring spacious and smooth material transportation. The equipment has self-cleaning ability to reduce residues; good airtightness and dust control.

Applicability: The twin shaftless screw feeder is suitable for handling materials that are highly viscous, prone to agglomeration (such as sludge and wet coal), prone to entanglement (such as fibers and rags), and large, irregularly shaped materials. Its enclosed design is also suitable for conveying odorous, toxic, or dusty materials.

What are the advantages of Twin Screw Feeder?

Twin Screw Feeder has significant advantages in bulk material conveying and precision feeding, such as strong anti-clogging ability, wide range of applicable materials, and closed conveying. Therefore, it is particularly good at handling material characteristics that other types of feeders have difficulty dealing with.

Strong anti-clogging ability: This is the outstanding advantage of Twin Screw Feeder. Two screws that mesh with each other and rotate in the same or opposite directions can produce a strong forced pushing effect on the material. This enables it to effectively solve the problem of blockage that may occur at the bottom of the silo or during the conveying process for materials with poor fluidity, easy bridging, easy bonding, containing fibers, or with a certain humidity, ensuring continuous and stable output of materials.

Precise metering and high feeding accuracy: The unique structure and operation mode of the twin screw make it have high accuracy in volumetric feeding. By accurately controlling the screw speed, the material flow can be output stably to ensure the accuracy of the downstream process formula.

Self-cleaning characteristics and reduced adhesion: The meshing rotation of the two screws forms a relative movement on the screw surface, which produces a kneading and peeling effect on the material. This "self-cleaning" feature can effectively reduce the adhesion and accumulation of materials on the screw surface and the inner wall of the trough, avoid cross-contamination caused by material residues, and reduce the frequency and difficulty of cleaning and maintenance. It is especially suitable for handling sticky materials.

Wide range of applicable materials: Due to its strong forced conveying ability and anti-clogging characteristics, Twin Screw Feeder can handle a very wide range of materials, including powders with poor fluidity, materials that are easy to bridge, sticky materials, fibers or flakes, high specific gravity or low specific gravity materials, etc.

Closed conveying: Twin Screw Feeder usually adopts a fully enclosed structure to effectively prevent dust spillage and material leakage. This not only improves the cleanliness of the working environment, reduces the impact on operators, but also protects the conveyed materials from external contamination.

Twin Screw Feeder parameters

| Specification | Main technical performance | Drive device | Drive device | Weight(kg) | |||

| Diameter | Length(m) | Yield( t/h) | Rotating speed(min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

What are the applications of Twin Screw Feeder?

Twin Screw Feeder plays a role in a variety of industrial and production scenarios. Its core function is to accurately, stably and forcibly convey various types of bulk materials, especially those with poor fluidity, easy to bridge or strong viscosity.

Continuous material supply: Twin Screw Feeder is often used as the core feeding unit on the production line, responsible for stably conveying powdered and granular materials in the upstream silo or hopper to the downstream mixer, reactor, extruder or drying equipment. Its forced conveying characteristics ensure that even in the face of difficult-to-handle materials, it can achieve uninterrupted continuous feeding and ensure the smoothness of the production process.

Accurate batching and feeding: In the production process where the formula ratio needs to be strictly controlled, Twin Screw Feeder can provide highly accurate volumetric or loss-in-weight feeding. It is often integrated with a weighing system to achieve accurate metering and dosing of materials, ensuring that multi-component materials enter the mixing or reaction stage according to the preset ratio, which is crucial for the stability and consistency of product quality.

Handling difficult-to-convey materials: Its unique twin-screw structure enables it to perform well in handling materials with poor fluidity, easy to agglomerate, easy to bridge, strong viscosity or containing fibrous substances. For example, for some wet powders, cellulose, pigments, additives, etc., a single screw or other feeding equipment may be blocked or have poor feeding, while the Twin Screw Feeder can effectively overcome these problems and achieve stable conveying.

Dust control: Twin Screw Feeder usually adopts a fully enclosed design, which can effectively prevent dust leakage during material conveying and reduce material loss. This is especially important for handling toxic, harmful, odorous or powder materials with high requirements for environmental cleanliness.

Material conveying in high or low temperature environments: Some Twin Screw Feeders can be designed with heating or cooling jackets to regulate the temperature of materials during conveying. This makes it suitable for material conveying scenarios that require maintaining a specific temperature, such as preheating materials before a reaction or cooling them after a reaction.

What are the uses of Twin Screw Feeder?

Twin Screw Feeders have a wide range of applications. Firstly, they play a crucial role in food processing and feed production, particularly in processes requiring precise dosing and complex material handling. In food processing, they are used to convey and meter various powdered and granular food ingredients, such as flour, starch, powdered sugar, cocoa powder, coffee powder, as well as various food additives and seasonings. They ensure a stable and continuous flow of these materials along the production line, preventing caking or sticking, thereby ensuring accurate product formulations and consistent end-product quality. For example, in baking, candy making, or beverage preparation, precise dosing of trace additives is crucial. In feed production, Twin Screw Feeders are used to precisely mix grains (such as cornmeal and soybean meal), bran, protein powder, vitamin premixes, and mineral additives in animal feed, aquafeed, and pet food. These raw materials have varying physical properties, some fluffy, others sticky. Twin Screw Feeders effectively address bridging and blockage during conveying, ensuring that the different components are mixed in the desired proportions, resulting in a nutritionally balanced feed product. Furthermore, in the building materials industry, Twin Screw Feeders are primarily used for conveying and batching various powdered or granular building materials. In the production of cement, lime powder, mineral powder, dry-mix mortar, and specialty mortars, Twin Screw Feeders control material flow and achieve precise metering. For example, in concrete batching plants, they precisely control the amount of cement and fly ash, among other binders, to ensure concrete strength, workability, and durability.

Twin Screw Feeder Price

The price of a Twin Screw Feeder varies depending on a variety of factors, ranging from US$400 to US$6,000 or even higher. The specific price range depends on several key factors, including the equipment's complexity, material, level of automation, and brand. The following factors primarily influence the price of a Twin Screw Feeder. The size of the equipment directly affects its manufacturing cost and material handling capacity. Feeders with larger handling capacity, larger screw diameter, and longer length require more materials, are more complex to manufacture, and naturally command a higher price. The material of the feeder's material-contacting parts is a significant factor in determining price. For example, carbon steel may be used for standard bulk materials, resulting in a relatively low cost. However, for materials that are corrosive, abrasive, or require strict hygiene requirements, stainless steel (such as 304, 316L) or even higher-grade specialty alloy steels may be required, significantly increasing costs. Wear-resistant liners and special coatings can also increase the price. The brand, type, and power of the motor and reducer directly impact the price. Choosing a high-efficiency or explosion-proof motor and reducer will improve performance and reliability, but also increase costs. The higher the level of automation, the higher the price. Standardized Twin Screw Feeders are generally less expensive. However, if customers have special needs, such as special inlet and outlet designs, tilt angles, heating or cooling functions, explosion-proof requirements, cleaning convenience designs (such as quick-disassembly structures), etc., these non-standard customizations will increase design and manufacturing costs.

Twin Screw Feeder plays a role in the current material handling process. Its advantage is that it can force the material to be conveyed, which helps to overcome the conveying difficulties of materials with poor fluidity, easy bridging or strong viscosity. At the same time, the equipment can achieve stable feeding of materials and has self-cleaning characteristics to a certain extent, reducing the accumulation of materials on the screw. When selecting a model, it is necessary to consider factors such as the specific physical properties of the material, the required feeding accuracy, and the on-site environment (such as whether anti-corrosion and dust control are required).