Cardamom Inclined Belt Conveyor

The price of a Cardamom Inclined Belt Conveyor ranges from $240 to $4,500, depending on the type, size, material, and functional configuration.

Size (length × width × height): 1*0.5-0.8*0.8 m/customized

Material: stainless steel/pvc/carbon steel

Speed: 1-25m/min variable

Belt width: 400/500/1500mm/customized

Capacity: 40kg/customized

Voltage: 110V/220V/380V

What is Cardamom Inclined Belt Conveyor?

Cardamom Inclined Belt Conveyor is a key piece of equipment for smooth material transfer. Its inclination angle can be adjusted to meet specific needs, from a slight slope to a vertical lift. Depending on the operating conditions, the equipment is available in standard, patterned, and high-angle sidewall types. Its flexible handling capacity allows a single unit to convey capacities ranging from several tons to tens of tons per hour, and conveying distances from a few meters to hundreds of meters.

What are the types of Cardamom Inclined Belt Conveyors?

Based on the conveying angle and material characteristics, Cardamom Inclined Belt Conveyors are categorized as standard, patterned, and high-angle sidewall conveyors. Each type has its own unique characteristics, adapting to different production environments and space constraints, effectively solving cardamom conveying tasks under various working conditions.

Standard Inclined Belt Conveyor

Features: This is the most common type, suitable for applications with shallow inclination angles. It uses a flat belt or a belt with a low pattern. Because the inclination angle is shallow, materials (such as cardamom) can be conveyed stably through their own friction, preventing them from slipping. Due to its simple structure, manufacturing and maintenance costs are relatively low. It is suitable for conveying granular, powdery, and bulk materials such as grain, sand, and coal.

Applicable Angle: Generally between 0 and 20 degrees. If the angle exceeds this range, the material may begin to slip.

Patterned Belt Conveyor

Features: The conveyor belt surface features raised patterns such as herringbone, herringbone, or diamond. These patterns significantly increase friction between the belt and the material, effectively preventing the material from sliding during conveyance. It is particularly suitable for conveying bagged items, packaging boxes, bulk materials, and other bulk materials with low friction, effectively preventing the material from rolling or sliding when tilted.

Applicable Angle: Inclined angles can reach 20 to 35 degrees.

High-Angle Sidewall Belt Conveyor

Features: The conveyor belt has corrugated sidewalls on both sides, creating a trough to prevent material spillage. Horizontal partitions on the belt surface separate the material into smaller, independent units, preventing the material from sliding. Because it can convey at large angles or even vertically, it significantly saves space and is ideal for workspaces with limited space. It can continuously and stably convey large quantities of material, and is particularly suitable for bulk materials requiring high-efficiency lifting.

Applicable Angles: Inclined angles can range from 35 to 90 degrees, making it particularly suitable for high-level conveying in confined spaces.

What are the advantages of the Cardamom Inclined Belt Conveyor?

The Cardamom Inclined Belt Conveyor's primary advantage lies in its ability to stably convey materials at varying heights. It also features a variety of adaptable designs, including ease of maintenance and compliance with food hygiene standards. The following are its specific advantages:

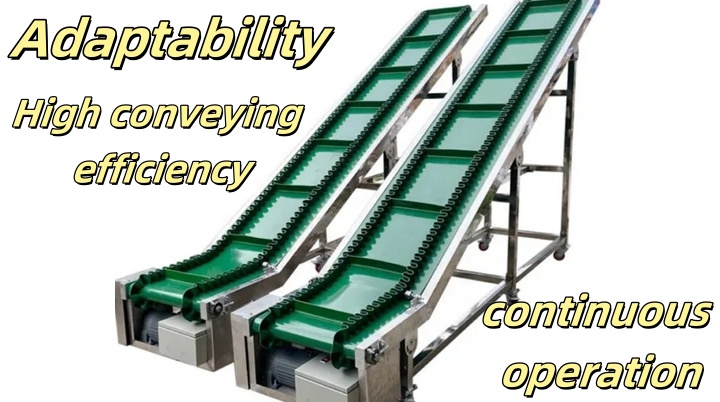

Adaptability: A variety of conveying angles: The Cardamom Inclined Belt Conveyor allows for different belt types to accommodate various inclination angles, depending on the actual needs of the production line. For small-angle conveying, ordinary flat belts can be used, offering a simple structure and low cost. For medium-angle conveying, patterned belts can be used to effectively prevent material from sliding and improve conveying efficiency. For large-angle or even vertical conveying, a sidewall belt conveyor is required. This allows for elevated material heights within limited space, significantly saving floor space.

High conveying efficiency and continuous operation: Inclined belt conveyors enable continuous conveying. Whether it's large quantities of fresh cardamom or processed dried cardamom, they can be transported stably and quickly from one process to the next, ensuring smooth production line operation.

Protecting material integrity and reducing breakage: Compared to some vibrating or bucket elevators, inclined belt conveyors cause less impact and compression on the cardamom during conveying. This smooth conveying method effectively protects the integrity of the cardamom, reducing breakage and material loss, which is particularly important for ensuring product quality.

Easy maintenance and low operating costs: This type of conveyor has a relatively simple structure, consisting primarily of a belt, rollers, a frame, and a drive unit. Daily maintenance and servicing are minimal, focusing primarily on belt tensioning and roller lubrication. Furthermore, due to relatively low energy consumption, long-term operating costs are also advantageous.

Easy to clean and meets food hygiene standards: Food materials like cardamom have very strict hygiene requirements. Inclined belt conveyors typically feature an open design, making them easy to clean and disinfect. Belt materials can also be made of food-grade materials to ensure hygienic and safe conveying.

Parameters of the Cardamom Inclined Belt Conveyor

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

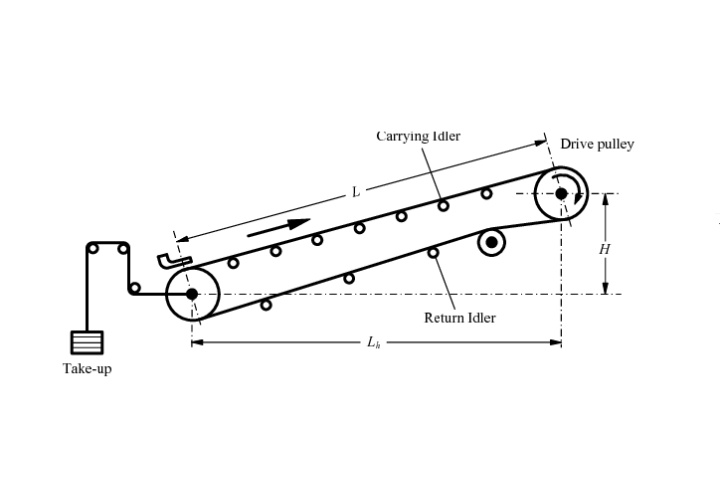

How does the Cardamom Inclined Belt Conveyor work?

The Cardamom Inclined Belt Conveyor's core operating principle is to utilize friction to drive the belt and thus the nutmeg. However, it also features an incline conveying feature to accommodate uneven conveying. Its basic operating principle is that the drive system (motor and reducer) drives the conveyor belt in a circular motion via a drive roller. The nutmeg is placed on the belt and moves along with it due to friction between the belt and the nutmeg. The entire system is supported by a frame and rollers, ensuring smooth belt operation. To overcome the effects of gravity, different inclination angles are used for incline conveying. At low inclination angles, the static friction between the nutmeg and the belt is sufficient to offset gravity, ensuring stable conveying. However, as the angle increases, friction alone is no longer sufficient to prevent the nutmeg from sliding down. Specially designed belts are used for conveying at steep angles. For example, patterned belts increase the coefficient of friction to enhance slip resistance. High-angle sidewall belts, on the other hand, use sidewalls and transverse partitions to form a "hopper" that completely encloses the cardamom, effectively preventing it from slipping and spilling even during vertical conveyance. In short, the Cardamom Inclined Belt Conveyor utilizes a drive system to generate power, using the friction of the belt to smoothly and continuously transport materials from low to high locations. The appropriate belt design is selected based on the inclination angle to ensure a stable and safe conveying process.

What are the Applications of the Cardamom Inclined Belt Conveyor?

The Cardamom Inclined Belt Conveyor is widely used in various industries. Its core function is to achieve stable and continuous material transportation between different heights. Examples include material transfer and lifting, connecting processing processes, and optimizing space. In large warehouses, it can transport cardamom from the ground to the shelf level, or transfer materials between different floors. This significantly improves storage efficiency and reduces the labor intensity of manual handling. On an automated production line, it transports cardamom from the sorting equipment to the packaging machine, ensuring a continuous supply of material and improving the production line's automation and efficiency. After cleaning, the cardamom is transported to the drying equipment in the next stage via an inclined belt conveyor. By adjusting the inclination angle, the conveying speed of the cardamom can be controlled, allowing the cardamom to drain on the belt before drying. Before grinding, the conveyor lifts the cardamom from the raw material bin to the grinder's inlet. After grinding, the ground cardamom is transported to the screening machine, completing the continuous crushing and grading process. When production space is limited, a high-angle sidewall belt conveyor can be used to lift the cardamom vertically, effectively utilizing vertical space and saving valuable floor space. This is particularly important in multi-story factories or workshops with compact layouts. Inclined belt conveyors act as a "bridge" between equipment at different heights, smoothly connecting upstream and downstream processes without the need for complex lifting devices or extensive labor, streamlining the entire production process.

Cardamom Inclined Belt Conveyor Price

The price of a Cardamom Inclined Belt Conveyor varies significantly depending on its type, specifications, and configuration. Generally speaking, the price range from $240 to $4,500. Many factors influence the price of a Cardamom Inclined Belt Conveyor, but they can be primarily categorized as follows:

Conveyor Type: Standard incline belt conveyors have a simple structure and are the cheapest. Patterned belt conveyors have higher belt costs, leading to a higher price. High-angle sidewall conveyors are the most complex, with higher belt and spacer manufacturing costs, resulting in a higher price.

Dimensions: The longer the conveyor, the more belt, frame, and roller materials required, resulting in a higher price. The wider the belt, the more material it can carry, but the cost also increases. The higher the lift height, the greater the conveyor's inclination angle may be, placing higher demands on the belt and structure, and naturally increasing the price.

Material and Configuration: The frame material, whether plain carbon steel, stainless steel, or plastic-sprayed steel, increases in price. The food-grade industry often chooses stainless steel to meet hygiene standards, which significantly increases costs. Belt materials, such as ordinary rubber, food-grade PU, and PVC, vary significantly in price.

Additional Features and Customization Requirements: Adding dust covers to prevent cardamom dust and contamination increases costs. Conveyors with casters or other mobile features have higher structural and manufacturing costs than fixed equipment. Customization based on specific customer requirements (such as environmental adaptability and specialized structural designs) also increases prices.

Choosing the right type of Cardamom Inclined Belt Conveyor depends on specific application conditions. These include site space, material conditions, conveying height, and distance. Each type of equipment has its own application. Standard types offer a simple structure, patterned belt types can handle moderate slopes, and high-angle sidewall types are specifically designed for conveying cardamom at different heights. These devices, with their unique designs, address the practical challenges of transferring cardamom at varying heights and are essential components of factory production lines.