Inclined Screw Conveyor

The price of Inclined Screw Conveyor varies depending on factors such as material, size, inclination angle and manufacturer. Its price ranges from $100 to $6,000.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

What is Inclined Screw Conveyor?

Inclined Screw Conveyor is a device used for conveying bulk materials. This type of equipment is usually classified according to the inclination angle of its conveying, covering a variety of forms from slight inclination to near vertical. The material handling capacity and actual conveying distance of the equipment will be affected by factors such as screw diameter, rotation speed, inclination angle, and physical properties of the material itself (such as bulk density, friction coefficient). In practical applications, there are specific ranges for the amount of material that a single Inclined Screw Conveyor can handle and the conveying height that can be achieved. They provide solutions for vertical or oblique movement of materials in different production environments.

What are the types of Inclined Screw Conveyor?

Inclined Screw Conveyor is a common type of screw conveyor. It is between horizontal and vertical conveying and is used to lift or convey materials at a certain inclination angle. According to the different inclination angles, Inclined Screw Conveyor can be roughly divided into the following types:

Micro Inclined Screw ConveyorThis type usually refers to a screw conveyor with a very small inclination angle, close to horizontal conveying.

Inclined angle range: usually between 0° and 10° (or less, such as 5°).

Features: While maintaining a nearly horizontal conveying capacity, it can overcome a small amount of height difference or be used to assist the smooth transition of materials. At this time, the material still mainly relies on the thrust of the screw and its own gravity to slide in the trough.

Medium Inclined Screw ConveyorThis is a common application range for Inclined Screw Conveyor.

Inclined angle range: usually between 10° and 30° (or 35°).

Features: At this angle, the conveying efficiency of the material will gradually decrease, but it can still maintain a good conveying capacity. The sliding friction characteristics of the material and the screw speed need to be considered during design to avoid material falling back.

When the inclination angle is large, the gravity of the material has a more significant effect on the conveying, and special design is required to ensure the conveying effect.

Inclined angle range: usually between 30° (or 35°) and 60° (or 70°).

Features: Under such a large inclination angle, the coordination between the spiral blade and the trough, the spiral speed and the structure of the spiral blade (such as adding ribs, using variable pitch, etc.) become particularly critical to prevent the material from sliding down in large quantities due to gravity during the conveying process, affecting the conveying efficiency. The conveying capacity will be significantly reduced.

Vertical Screw ConveyorInclined Angle Range: 90°.

Features: The material is lifted completely by the centrifugal force generated by the high-speed rotation of the spiral and the driving force of the spiral blade. Usually a higher speed and a smaller radial clearance are required, and higher requirements are placed on the fluidity of the material.

What are the advantages of Inclined Screw Conveyor?

As a specific conveying equipment, Inclined Screw Conveyor shows its unique advantages in a variety of industrial scenarios, such as high space utilization, relatively compact structure, relatively simple maintenance, and adaptability to material diversity.

High space utilization: Inclined Screw Conveyor can simultaneously realize the functions of horizontal conveying and vertical lifting. Compared with a single horizontal conveyor and bucket elevator combination, it can complete the height difference conveying of materials at an inclined angle in a smaller footprint, saving valuable plant space. This is particularly beneficial for production lines with limited space.

Relatively compact structure: Compared with belt conveyors or long-distance horizontal conveyors, Inclined Screw Conveyor has a more compact structure and the equipment itself is relatively small. Its closed or semi-closed trough design also makes the entire conveying system simpler and easy to integrate into existing production lines.

Relatively simple maintenance: Most Inclined Screw Conveyors use U-shaped troughs or easily disassembled pipe structures, making it relatively convenient to inspect and clean the internal materials. Key components such as spiral blades and bearings are usually designed to be easy to replace, reducing the complexity of maintenance and downtime.

Adapt to material diversity: Inclined Screw Conveyor can handle a variety of bulk materials, including powders, granules, small blocks and some sticky materials. By adjusting the pitch, diameter, material, and running speed of the spiral blade, it can adapt to the conveying characteristics of different materials and reduce the fall of materials during the tilting process to a certain extent.

Easy to achieve material sealing: Although not as completely sealed as vertical screw conveyors or pneumatic conveyors, compared with open belt conveyors, when the Inclined Screw Conveyor is covered on the U-shaped trough or adopts a tubular structure, it can effectively reduce the dust spillage of the material and prevent the entry of external impurities, which is advantageous for occasions with certain requirements for the environment or material purity.

Parameters of Inclined Screw Conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

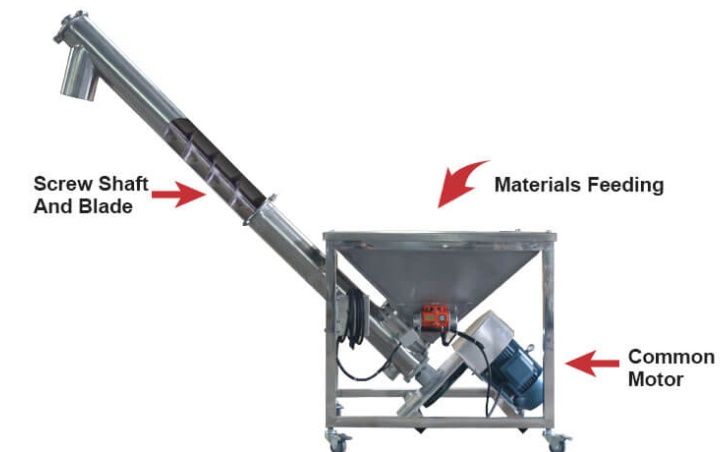

What are the structures of Inclined Screw Conveyor?

Inclined Screw Conveyor is a common form of bulk material conveying equipment. Its structural design is designed to achieve the lifting and conveying of materials at a certain tilt angle. The core component of Inclined Screw Conveyor is the spiral body. The spiral body consists of spiral blades and spiral shafts. The spiral blade is the key part that directly pushes the material. Its shape, pitch and thickness are customized according to the nature and conveying requirements of the conveyed material. The screw shaft is usually a solid or hollow cylinder, which is used to support the blades and transmit power. The screw is installed inside a U-shaped trough or tubular housing. The U-shaped trough is more common when conveying materials that are easy to clean or need to be observed due to its openness, but it needs to be covered to prevent material spillage. The tubular housing provides a fully enclosed conveying environment, which is particularly suitable for occasions with high dust control, high hygiene requirements or the need to prevent the material from getting wet. The material of the trough or housing is usually carbon steel or stainless steel, depending on the corrosiveness and hygiene requirements of the material. During the conveying process, the screw needs stable support. This is usually achieved through the head, tail bearings and intermediate hanging bearings. The head bearing and tail bearing are located at both ends of the conveyor, respectively, to bear the radial and axial loads of the screw. For longer Inclined Screw Conveyors, intermediate hanging bearings are set to support the screw to prevent it from deflecting under its own weight and material load, ensuring smooth operation. The power source usually consists of a motor and a reducer, which together constitute the drive device. The drive unit is installed at one end of the conveyor (usually the discharge end or head), and transmits power to the screw shaft through the coupling to rotate it. The power of the motor and the speed ratio of the reducer are calculated and determined according to the handling capacity, inclination angle and material characteristics of the conveyor. The material enters the conveyor through the feed port, moves along the inclination direction under the push of the spiral blade, and finally discharges from the discharge port. The design of the inlet and outlet needs to match the upstream and downstream equipment and take into account the flow characteristics of the material to ensure smooth feeding and unloading. In addition, the Inclined Screw Conveyor may also include auxiliary structures such as observation windows, cleaning ports, and safety shields to facilitate daily operation, maintenance and ensure personnel safety.

What are the applications of Inclined Screw Conveyor?

The main function of Inclined Screw Conveyor is to realize the lifting and conveying of materials, smoothly conveying materials at a lower position to a higher position, or transitioning between different process levels. The equipment can handle a wide range of materials, including but not limited to various types of powdered materials (such as flour, cement, carbon powder, etc.), granular materials (such as grains, plastic particles, sand, etc.) and some small block materials. In some cases, it can also be used to convey materials with a certain viscosity or semi-fluid state, but the spiral blades and trough design need to be adjusted in a targeted manner. Inclined Screw Conveyor is usually used in the following scenarios:

First, in the storage and unloading of materials. For example, the material unloaded from the ground or truck is lifted to the top of the silo for storage, or the material at the bottom of the silo is sent out through an inclined conveyor for further processing or packaging.

Second, in the material transfer in the production process. When different process units are located at different heights, the Inclined Screw Conveyor can serve as a bridge connecting these units. For example, after the material is output from the mixing equipment, it is lifted to the entrance of the screening machine or dryer; or the material that has been preliminarily processed is conveyed to the feeding port of the next production line.

Furthermore, in the auxiliary processing link. Sometimes, the Inclined Screw Conveyor is not only used for simple conveying, but also can be combined with other functions. For example, simple stirring or mixing is performed during the conveying process so that the material can be preliminarily homogenized while being lifted; or as part of a metering feeding system, the material conveying volume is adjusted by controlling the speed.

In addition, the Inclined Screw Conveyor also plays a role in the treatment of waste or by-products. For example, the waste residue and waste generated during the production process are collected and lifted, and transported to the recycling area or temporary storage point.

Its adjustable inclination angle enables it to flexibly adapt to different on-site space and lifting height requirements, providing a practical solution for the vertical transfer of various bulk materials.

The Inclined Screw Conveyor provides a means of material transfer in a variety of industrial scenarios. Its structural adaptability enables it to cope with different site restrictions and height difference requirements. The equipment is designed to take into account the properties of the material, such as fluidity, abrasiveness, and whether it is easy to entangle, to ensure that the material can be effectively lifted and conveyed. Although its functionality is primarily focused on the diagonal transfer of materials, in specific applications it helps maintain the continuity of production processes and supports the movement of materials between different processing stages.