Sludge Screw Conveyor

The price of Sludge Screw Conveyor varies depending on its model, material, screw diameter, and shaftless design. The price usually ranges from US$300 to US$6,800.

Rotation speed: 45-70 R/Min

Size (L*W*H): 2000*200 * 220mm/customizable

Frame material: carbon steel/stainless steel

Power: 0.4kW-22kW

Voltage: 220V/380V/415V

Frequency: 50/60Hz

What is Sludge Screw Conveyor ?

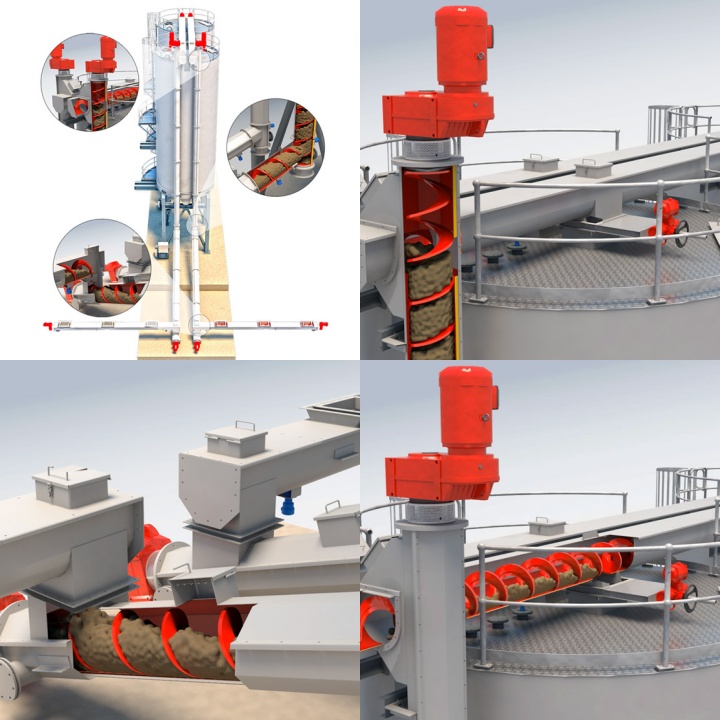

Sludge Screw Conveyor is a device used to transfer sludge and similar viscous bulk materials in various industrial and municipal environments. This type of conveyor mainly includes shaftless screw conveyors based on its spiral structure. The shaftless design has the characteristics of anti-winding; at the same time, it can be divided into trough type or tube type according to the casing form to adapt to different airtightness and cleaning requirements. In terms of material handling capacity, Sludge Screw Conveyor can handle sludge from several cubic meters to tens of cubic meters per hour, and the conveying distance of a single device usually ranges from several meters to more than 20 meters.

What are the types of Sludge Screw Conveyors?

Sludge is a special material with high water content, strong viscosity, easy to agglomerate, easy to entangle, and often contains odor. Therefore, the design of the Sludge Screw Conveyor is different from that of the screw conveyor for ordinary materials, mainly emphasizing its anti-blocking, corrosion resistance, and good sealing characteristics.

Features: This is a more common and recommended type for conveying sludge. It has no central shaft, only a flexible spiral body rotating in a U-shaped groove (or tube). The spiral body is usually made of high-strength, wear-resistant steel (such as special alloy steel, stainless steel), and the inside of the groove body is lined with wear-resistant ultra-high molecular weight polyethylene or other low-friction materials.

Advantages: It can solve the problem of material winding around the central shaft, and is particularly suitable for conveying sludge with high viscosity, easy winding (such as containing fibers, hair, etc.), and easy agglomeration. Since there is no intermediate bearing, the blockage point and maintenance requirements are greatly reduced. The conveying space is larger and can handle larger pieces of sludge.

Features: The spiral body runs in a U-shaped or O-shaped groove body, and the top of the groove body usually has a removable cover plate for easy maintenance and cleaning.

Advantages: Sludge Screw Conveyor mostly adopts a groove structure (especially a U-shaped groove), which is convenient for the installation and operation of the shaftless spiral, and also facilitates the cleaning of the inside of the groove body, especially when the sludge adheres to the wall. The groove body is usually made of stainless steel to improve corrosion resistance.

What are the advantages of Sludge Screw Conveyor?

Sludge Screw Conveyor is designed for handling special materials such as sludge, so it has significant advantages in dealing with the challenges of sludge. Such as anti-winding and anti-blocking, corrosion resistance, stable operation, etc.

Excellent anti-winding and anti-blocking capabilities: This is the core advantage of Sludge Screw Conveyor. Most sludge conveyors adopt a shaftless spiral design, eliminating the center shaft and intermediate hanging bearings. This prevents common fibers, hair, plastic sheets and other debris in the sludge from winding, and greatly reduces the risk of blockage caused by agglomeration or bridging of high-viscosity sludge, ensuring continuous and smooth transportation of materials.

Strong airtightness: Sludge usually contains odor and may contain harmful substances. Sludge Screw Conveyor (especially tubular or trough type with tight cover) adopts a fully enclosed structure, which can effectively prevent the spread of odor and material leakage generated during the transportation of sludge, and significantly improve the sanitary conditions and air quality of the working environment. This is crucial for sewage treatment plants, chemical plants and other places.

Strong structure and good corrosion resistance: Sludge is corrosive. The parts of Sludge Screw Conveyor that come into contact with the material are usually made of corrosion-resistant stainless steel (such as 304 or 316L), and the inside of the tank is treated with wear-resistant lining. This design ensures the long-term stable operation of the equipment in harsh working environments, extends its service life, and reduces the frequency of replacement and maintenance.

Flexible conveying angle: Sludge Screw Conveyor can achieve horizontal, inclined and even vertical conveying. This multi-directional conveying capability enables the equipment to be flexibly arranged according to the needs of on-site space and process flow, effectively utilize space, reduce material transfer links, and simplify the system.

Sludge Screw Conveyor Options

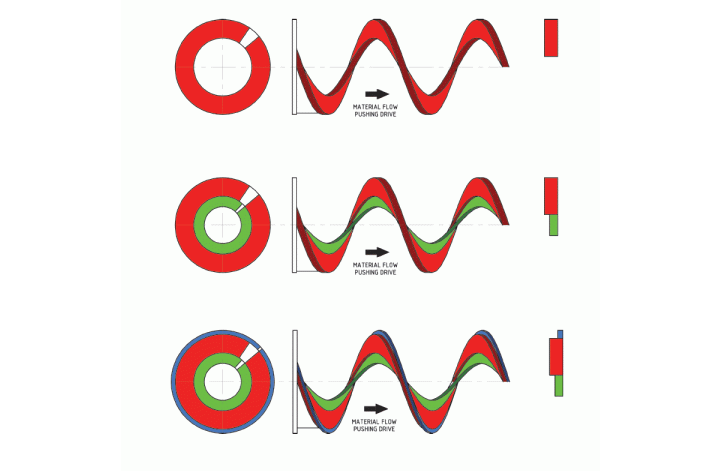

As a key piece of solid waste handling equipment, the sludge screw conveyor's layout and blade pitch design directly impact conveying efficiency, equipment adaptability, and operational stability. Layouts are primarily categorized as horizontal, inclined, and vertical. The horizontal layout is the most widely used, suitable for short-distance, low-lift sludge conveying. It features a simple structure and easy maintenance. The inclined layout is used when sludge needs to be lifted to a certain height, but as the inclination angle increases, the conveyor's handling capacity decreases. To ensure smooth sludge conveying, the inclination angle is generally kept below 20 degrees. The vertical layout is primarily used in special applications where space is limited or sludge needs to be conveyed to a higher location. Shaftless screw conveyors are typically used to prevent sludge from tangling around the central shaft and causing blockage, but their structure is also more complex.

Blade pitch, commonly known as screw pitch, is another key parameter affecting sludge conveyor performance. There is no fixed standard for selecting screw pitch; it is generally determined based on the sludge's moisture content, viscosity, density, and conveyor speed. Generally speaking, for sludge with poor fluidity and high viscosity, a larger pitch is often used to reduce material accumulation and adhesion between the spiral blades, thereby improving conveying efficiency. A larger pitch also effectively reduces motor load. Conversely, for sludge with a higher moisture content and better fluidity, a smaller pitch can be used to prevent material slippage during conveying. Furthermore, the ratio of pitch to spiral diameter is a crucial design consideration. Proper blade spacing ensures a stable sludge flow during conveying, preventing blockage and backflow. Therefore, both the layout and blade spacing must be customized based on the specific sludge characteristics and process requirements.

Parameters of Sludge Screw Conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the applications of Sludge Screw Conveyor?

Sludge Screw Conveyor is used in many links that need to handle water-containing, viscous, entangled or odorous bulk materials. Its core function is to transfer such challenging materials safely, closed and continuously. Its application scenarios include:

Solid waste transfer and disposal: In various solid waste treatment processes, Sludge Screw Conveyor is used to transport solid waste with a certain water content from one treatment stage to the next. For example, it can transport dehydrated filter cakes, slag intercepted by gratings, ash after incineration, etc. from the bottom of dehydration equipment, collection tanks or incinerators to subsequent storage, transportation or further processing units. Its airtightness effectively controls the spread of odors and pollutants.

Material stirring and mixing: In addition to the simple conveying function, Sludge Screw Conveyor sometimes also has stirring or mixing functions. Through specially designed spiral blades or multi-spiral combinations, materials can be fully mixed during the conveying process, which is particularly applicable when multiple sludges need to be homogenized or flocculants and conditioners need to be added to the sludge.

Material lifting and height difference conveying: When space is limited or materials need to be conveyed to equipment at different heights, Sludge Screw Conveyor can achieve horizontal, inclined or even vertical conveying. This enables it to convey sludge from the ground to high silos, filter press feed ports or higher-level processing equipment, thereby optimizing plant layout and process flow.

Isolation and conveying of special materials: For sludge that may contain toxic and harmful substances, highly corrosive media or emit strong odors, its fully enclosed conveying structure ensures the isolation of materials from the external environment. This not only protects the safety of operators and reduces environmental pollution, but also avoids secondary contamination of materials during conveying.

Sludge Screw Conveyor Case Study

The sludge screw conveyor, with its unique shaftless design, demonstrates significant advantages in handling a variety of high-viscosity, high-moisture, and easily entangled materials, thus playing a vital role in various industries. Its core application is sewage treatment plants. At the final stage of wastewater treatment, the sludge cake, after being processed by the dewatering machine, still has high viscosity and moisture content. This makes it prone to entanglement and accumulation on the central shaft of traditional conveying equipment, causing blockages and even equipment damage. The shaftless screw conveyor, with its shaftless spiral blades, effectively solves this problem, ensuring continuous and stable sludge conveyance and significantly reducing the frequency of manual cleaning and equipment maintenance. It is an indispensable key piece of equipment in wastewater treatment plants. Besides the wastewater treatment industry, the sludge screw conveyor also plays a role in the food processing and papermaking industries. Food processing generates a large amount of organic waste, such as fruit and vegetable scraps, meat and bone offal, which are often high in moisture content and sticky. The sludge screw conveyor safely and hygienically transports this waste to the designated location, preventing material leakage and cross-contamination, and meeting the strict equipment hygiene standards of the food industry. In the papermaking industry, pulp residue and wastewater sludge generated during production contain a high amount of fiber and are prone to entanglement. The sludge screw conveyor can easily handle this type of material, transporting it from the sedimentation tank to subsequent drying or incineration stages. In addition, the equipment is also used in waste disposal, animal husbandry and chemical industries to treat various industrial waste residues and domestic waste. It is an ideal choice for processing sticky and entangled materials.

Sludge Screw Conveyor plays a key role in the current sludge treatment process. The device achieves continuous movement of sludge through the rotation of spiral blades in the shell. Its structural design focuses on the stickiness, entanglement and corrosiveness of sludge, and usually adopts corrosion-resistant materials and anti-entanglement spiral structures to maintain the stable operation of the equipment. In the process of conveying sludge, and there are specific requirements for odor control, material leakage prevention or maintenance convenience, Sludge Screw Conveyor can provide a material transfer method that meets the actual application needs.