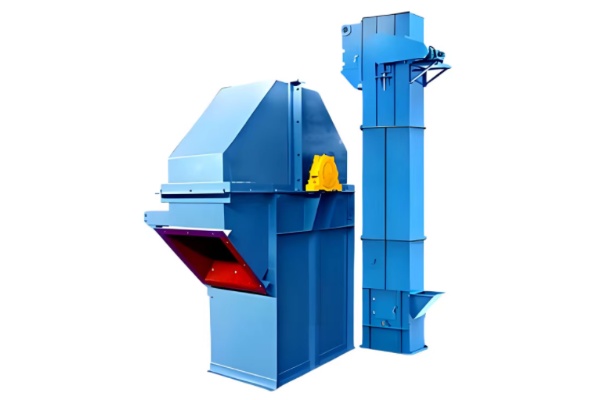

Sand Bucket Elevator

The price of a sand bucket elevator varies depending on its conveying capacity, lifting height and other factors, and usually ranges from US$300 to US$7,000.

Height: Max.40 meters

Bucket speed: 1.2 m/s

Bucket width: 315mm

Transmission type: belt/chain/chain plate

Lifting capacity: 0-60m3/h

Voltage: 220V/380V/50HZ/60HZ

What is Sand Bucket Elevator?

Sand Bucket Elevator , as a vertical material conveying equipment, is currently used in a variety of bulk material processing scenarios. Its main function is to lift the material from a lower position and discharge it at the top. This type of equipment mainly includes belt elevators with conveyor belts as traction parts and chain elevators with chains as traction parts according to their structural characteristics and material adaptability. Sand Bucket Elevator has a wide range of material handling capabilities, ranging from several tons to hundreds of tons of bulk materials per hour.

Sand bucket elevators are primarily categorized into two types: belt bucket elevators and chain bucket elevators. Belt bucket elevators are suitable for conveying dry, loose, and less abrasive materials, such as dry sand and stone dust. Chain bucket elevators are more suitable for conveying heavier, more abrasive, or hotter materials, such as wet sand, gravel, and slag. When selecting a model, consider the material's specific gravity, particle size, humidity, and temperature, as well as factors such as the lifting height, conveying capacity, and operating environment to ensure stable operation and a long service life.

What are the types of Sand Bucket Elevator?

Sand bucket elevators are used to lift bulk materials such as sand and gravel from low to high locations. Depending on their traction components, these types of equipment are primarily categorized into belt bucket elevators and chain bucket elevators. Each type has its own specific emphasis on structure, performance, and applicable operating conditions, and also differs in conveying distance and capacity.

Belt bucket elevatorBelt bucket elevator uses rubber or steel cord belt as traction component, and the bucket is fixed to the belt by bolts.

Conveying distance (lifting height): Belt elevator can achieve a higher lifting height, generally 30 meters to 100 meters or even higher, but the specific lifting height will be limited by the strength of the belt and the nature of the material.

Conveying capacity: Belt bucket elevator is usually used in occasions with large conveying capacity, because the belt can achieve higher operating speed, thus bringing greater conveying capacity. The specific conveying capacity depends on the bucket capacity, operating speed and material density, which can reach hundreds or even thousands of tons per hour.

Chain bucket elevator uses single or double chain as traction component, and the bucket is connected to the chain by buckles or bolts.

Conveying distance (lifting height): Chain elevators can also achieve higher lifting heights, especially for working conditions that need to withstand greater loads and impacts, and the lifting height can reach tens to hundreds of meters.

Conveying capacity: Chain bucket elevators also have a large conveying capacity, especially suitable for conveying large and heavy materials. The conveying capacity also depends on the bucket capacity, operating speed and material density, and can reach hundreds of tons per hour.

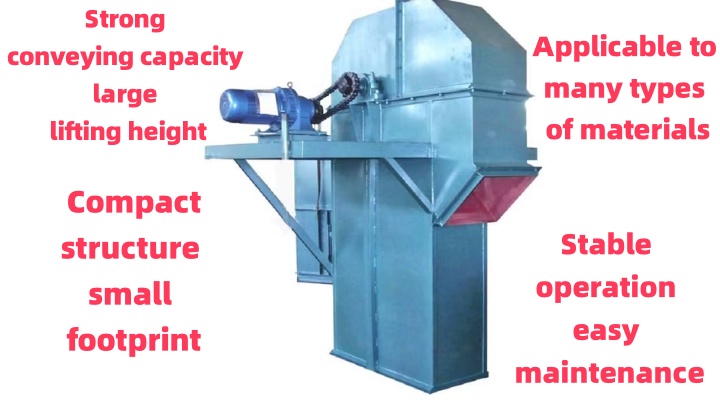

What are the advantages of Sand Bucket Elevator?

With its advantages in space utilization, material adaptability and operation stability, Sand Bucket Elevator has become a very practical and common equipment in the field of vertical transportation of bulk materials. It has the following significant advantages:

Vertical transportation capacity: Sand Bucket Elevator saves a lot of floor space and can lift materials vertically to a higher height. Realize continuous and stable material transportation to ensure smooth connection of production processes.

Excellent environment and material protection: The equipment adopts a fully enclosed design to effectively prevent dust flying and material spilling, improve the working environment and reduce material loss. At the same time, it can isolate external pollution to ensure the purity and quality of materials.

Strong material adaptability: Sand Bucket Elevator can transport a variety of granular, powdered and small block bulk materials, and optimize the transportation effect by selecting different types. Certain types (such as gravity type) have less damage to fragile materials and help maintain material integrity.

Easy to operate and maintain: The structure of the equipment is relatively simple, the operation reliability is high, and it can operate stably for a long time with proper maintenance. It is also easy to realize automatic control, reduce manual intervention, and reduce labor intensity.

Basic parameters of Sand Bucket Elevator

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

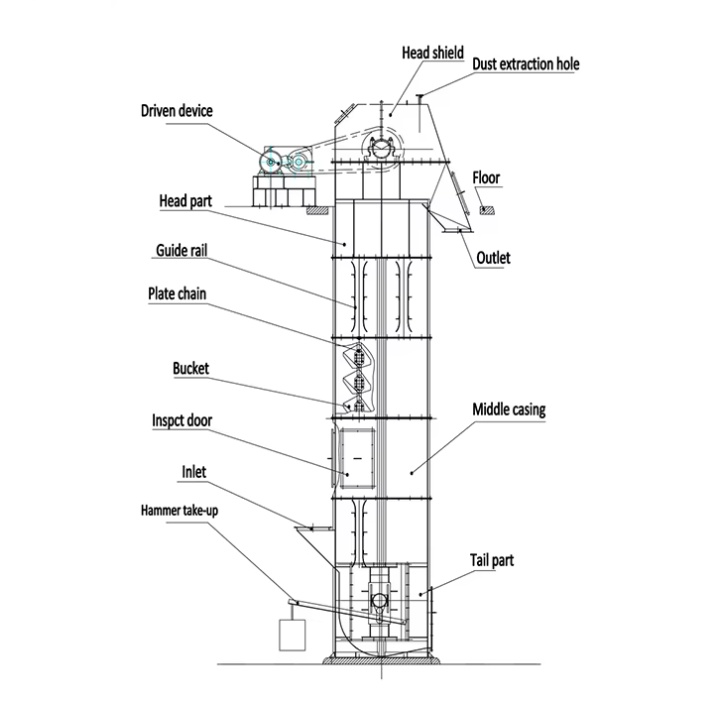

What is the structure of a sand bucket elevator?

The sand bucket elevator boasts a simple and practical design, consisting primarily of core components such as a drive unit, upper and lower casings, a traction member, a hopper, and a transmission. The drive unit, the power source for the elevator, typically consists of an electric motor, a reducer, and a coupling. Located at the top of the elevator, the drive unit drives the traction member (belt or chain) through the transmission, thereby lifting the material. The upper and lower casings form the main structure of the elevator and are typically fully enclosed. The upper casing houses the discharge port and drive wheel (or sprocket). When the hopper reaches the top, the material is discharged here by centrifugal force or gravity. The lower casing houses the feed port and a bend wheel (or sprocket). Material enters the feed port, where the hopper is diverted by the bend wheel, completing the loading process. The lower casing typically also features a tensioning device to adjust the tension of the traction member. The traction member is a key component that connects to the hopper and transmits power. Sand bucket elevators can be divided into two main types depending on the traction mechanism. One type uses a drive belt. In belt bucket elevators, high-strength, wear-resistant rubber or PVC belts are typically used. This type is suitable for conveying materials with low abrasiveness and low specific gravity. The other type uses a chain. In chain bucket elevators, high-strength, corrosion-resistant chains are used. This durable structure is more suitable for conveying materials with high specific gravity, high abrasiveness, or high temperatures. The hopper is the component that directly carries and conveys the material and is secured to the traction mechanism with bolts or other fasteners. The shape and material of the hopper vary depending on the material properties and conveying requirements. For example, hoppers used to convey powdered materials such as cement and lime typically have either a deep or shallow hopper design to accommodate the material's flowability. The transmission mechanism, consisting of a drive wheel, a bend pulley (or sprocket), and a traction mechanism, is responsible for transmitting the drive power to the hopper. It ensures stable and continuous operation of the hopper, completing the vertical conveying task.

What are the uses of a sand bucket elevator?

The Sand Bucket Elevator is designed to perform a range of functional tasks, such as vertical handling, centralized feeding, process connections, and storage and loading/unloading. These applications form the basis for its application across various industries. Its main uses can be summarized as follows:

Vertical conveying: It enables the continuous and stable lifting of bulk materials such as sand, gravel, cement, and grain from a lower level to a higher level. This application is crucial when materials need to cross height differences or when horizontal conveying equipment cannot be used to connect them.

Material Concentration and Feeding: In some production processes, materials flowing from various locations or equipment need to be concentrated and transported to a higher location for centralized processing or storage. The Sand Bucket Elevator can collect materials through multiple feeding points and then lift them to a designated location, providing a continuous and stable material flow for subsequent production processes.

Process Connection: The Sand Bucket Elevator is a key device that connects different production process stages. For example, it can transport materials processed by equipment such as crushers and grinders to the next process, such as mixers, screeners, or packaging machines. Its presence enables automation and continuity of the entire production line, reducing manual intervention during material handling.

Storage and unloading: In large bulk material storage systems, the Sand Bucket Elevator is typically used to lift materials to the top of the silo for loading. When unloading is required, it can also remove materials from the bottom of the silo and lift them to transport vehicles or the next level of conveying equipment. Its fully enclosed design also effectively reduces dust contamination and material loss during material transportation.

What are the applications of Sand Bucket Elevator?

The sand bucket elevator is a common vertical conveying device that lifts bulk materials such as sand and gravel from low to high locations. It is widely used in various material conveying and process connection scenarios. It is primarily used for vertical conveying and high-altitude unloading of bulk materials, thereby optimizing production processes and spatial layout. Sand bucket elevators are primarily used in the following scenarios:

Feeding from low to high: When materials need to be lifted from the ground, underground silos or lower production equipment to higher storage facilities (such as silos, silos) or subsequent processing equipment (such as mixers, packaging machines), Sand Bucket Elevator is a tool to achieve this vertical transfer.

Material collection and centralized transportation: In some scenarios where materials need to be uniformly lifted after being collected from multiple low points, Sand Bucket Elevator can collect materials from different feed ports and lift them to the designated high-level unloading point.

In and out of buffer and storage systems: In the feeding or discharging links of large bulk material storage facilities (such as silos or large material piles), Sand Bucket Elevator is often used to lift materials to the top of the silo for feeding, or to take them out from the bottom and lift them again to the next conveying equipment.

Material transportation in a closed environment: For materials that need to control dust, avoid material contamination or prevent moisture from entering, the fully enclosed design of the Sand Bucket Elevator enables it to complete the vertical transportation task of materials in a controlled environment.

High space utilization requirements: When the site space is limited and large-scale horizontal transportation cannot be arranged, the Sand Bucket Elevator can use the vertical space to greatly save floor space and achieve a compact equipment layout.

Sand Bucket Elevator Manufacturers

Sand Bucket Elevator is a key equipment for vertical conveying of bulk materials. In terms of traction components, Sand Bucket Elevator can be divided into belt type and chain type. Belt type is usually used to convey light, small, and low-noise materials, and has the characteristics of smooth operation and relatively simple maintenance. Chain type is suitable for conveying heavy, large, high-temperature or abrasive materials, with strong load-bearing capacity and impact resistance. Sand Bucket Elevator manufacturers have strong customization capabilities to meet the specific needs of different industries. For special material characteristics or complex working conditions, manufacturers can provide non-standard design solutions, including adjustments to hopper shape, material, lining, traction component type and structural layout. In addition to common carbon steel, manufacturers can provide a variety of material options such as stainless steel, wear-resistant steel, special alloy steel, etc. to cope with challenges such as corrosion, high temperature or high wear. Customization also includes the addition of special functions such as explosion-proof, dust-proof, corrosion-resistant, heating and heat preservation, as well as the provision of a variety of feeding and discharging devices, maintenance platforms, safety protection and other accessories. Through precise selection and customized services, Sand Bucket Elevator can meet the complex and changeable material transportation needs in various industrial production.

Sand bucket elevator solutions

The sand bucket elevator is widely used in various scenarios, including the cement and building materials industries, mining, and mineral processing, to meet the needs of vertical material conveying in various production processes. It can handle a variety of highly abrasive, high-temperature, and high-density bulk materials, and is one of the core devices for achieving production process automation, continuous material conveying, and high-altitude unloading.

Cement and Building Materials Industry

Cement plants are one of the common applications of Sand Bucket Elevators. They are used to transport a variety of highly abrasive and high-temperature materials.

Raw Material Transportation: Cement production requires a large amount of raw materials, such as limestone, clay, iron ore, etc.

Clinker Transportation: Clinker is an intermediate product in cement production and needs to be lifted to the clinker storage after calcination.

Pulverized Coal Transportation: Pulverized coal is often used as fuel for cement kilns. Sand Bucket Elevator is responsible for lifting pulverized coal from the storage silo to the burner system to ensure a continuous supply of fuel.

Finished Product Transportation: The ground cement powder will be lifted to the cement silo by the Sand Bucket Elevator for subsequent packaging and transportation.

Mining and Mineral Processing

Sand Bucket Elevators in the mining industry are used to handle various ores, coals and tailings.

Ore Lifting: Ore mined from underground mines or open pits can be lifted to the surface crushing station or beneficiation plant by large chain bucket elevators.

Coal transportation: After the coal comes out of the washing plant, it needs to be lifted to the coal storage bin or loading point. Tailings treatment: Tailings generated during the beneficiation process sometimes need to be transported vertically by bucket elevators for storage or further processing.

The structure and component selection of the Sand Bucket Elevator should be configured according to the characteristics of the processed materials and specific working conditions. The Sand Bucket Elevator usually has a certain material adaptability and can complete its vertical transportation tasks in different scenarios. The selection of a suitable Sand Bucket Elevator usually needs to be determined based on the specific working parameters such as the properties of the material to be transported (such as particle size, bulk density, abrasiveness, moisture content, etc.), the required conveying volume, the lifting height, and the feeding and discharging methods. When communicating with the manufacturer, providing detailed material information and process requirements is the basis for obtaining a suitable equipment configuration.