Oil Screw Conveyor

The price of Oil Screw Conveyor varies depending on the material, size, processing capacity, customization requirements and manufacturer. It ranges from $100 to $4,500.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

What is Oil Screw Conveyor?

Oil Screw Conveyor is a mechanical device used to transport various types of oil. This type of equipment can be divided into many types according to the structural form. Common ones include fully enclosed tubular screw conveyors and shaftless screw conveyors suitable for viscous materials. They can handle oils of different viscosities, with or without solid particles. The specific processing capacity of the equipment, that is, the amount of oil transported per unit time, will vary depending on the screw diameter, speed and oil characteristics. In actual layout, Oil Screw Conveyor can achieve horizontal, inclined or short-distance vertical transportation. The transportation distance of its single equipment is generally within tens of meters to meet the layout requirements of different production processes.

What are the types of Oil Screw Conveyor?

Oil Screw Conveyor is mainly classified according to its structural form and the characteristics of the conveying medium. Considering the general fluidity of oil (whether edible oil, fuel oil or industrial oil), the requirements for sealing and potential hygiene or safety considerations, the following are several common types of Oil Screw Conveyors:

Good sealing: prevents oil leakage, spillage and volatilization, especially suitable for flammable, toxic or environmentally polluting oils.

Sanitary: The fully enclosed structure reduces the risk of external impurities entering, is easy to clean, and meets the transportation requirements of food-grade oils.

Safety: It helps to isolate the oil from contact with air and reduce the risk of oxidation or combustion.

Compact structure: The footprint is relatively small.

Not easy to entangle: If the oil contains fibers, particles or other impurities that are easy to entangle, the shaftless design can effectively avoid blockage.

Conveying viscous materials: It has a good conveying capacity for high-viscosity, semi-fluid sludge, oily sludge, etc.

Easy to maintain (U-type): If it is a U-type trough shaftless screw conveyor, it is relatively convenient to inspect and clean.

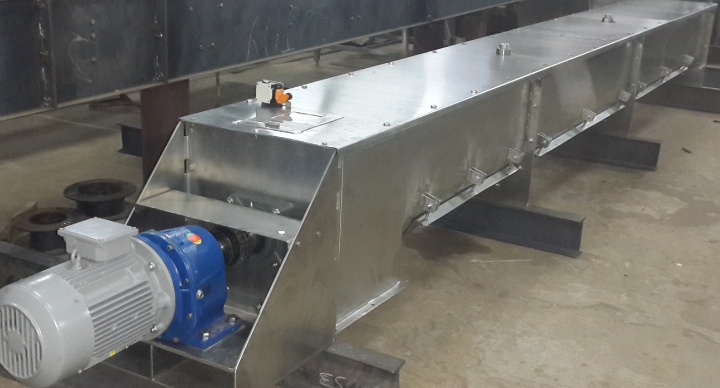

The spiral blades rotate in an open or semi-open U-shaped trough. Although it is used in the transportation of some semi-fluid or viscous materials (such as oily sludge, oil residue, etc.), U-type screw conveyors are generally not recommended for the transportation of pure liquid oil. This is mainly because its poor sealing performance can easily lead to oil leakage, overflow and safety hazards. The open structure is susceptible to external contamination. For oil with good fluidity, the U-shaped trough may cause a "short circuit" phenomenon and reduce the conveying efficiency. It is mainly used to convey some high-viscosity, oily solid waste or semi-solid sludge that does not require strict sealing, rather than liquid oil itself.

What are the advantages of Oil Screw Conveyor?

The transportation of oil is a key link in many industrial fields, and it puts forward unique requirements for the sealing, hygiene and operation stability of the equipment. In this context, Oil Screw Conveyor, with its unique design, has shown significant advantages in handling various types of oil.

Good closure: Compared with open conveying methods, screw conveyors, especially tubular screw conveyors, can achieve fully enclosed conveying. This effectively avoids leakage, volatilization and external contamination of oil during transportation, which is particularly important for flammable, toxic or environmentally stringent oils, and can significantly improve the safety of operation.

High sanitation: Due to its closed structure, external impurities are difficult to enter the conveying system, maintaining the cleanliness of the oil. This is crucial for the transportation of food-grade or industrial oils with strict purity requirements.

Small footprint: Screw conveyors are usually compact in design. Compared with other conveying equipment (such as belt conveyors), their linear or small-angle inclined conveying characteristics enable them to operate in limited areas, saving valuable space.

Relatively simple maintenance: For oils containing certain solid particles or high viscosity, screw conveyors (especially shaftless screw conveyors) are not prone to blockage or entanglement due to their structural characteristics, reducing the frequency and difficulty of cleaning and maintenance.

Strong adaptability: It can adapt to oils with different viscosities, temperatures, and whether they contain solid particles. By adjusting the spiral blade design, material, and drive system, it can meet a variety of oil transportation needs.

Oil Screw Conveyor Parameters

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the applications of Oil Screw Conveyor?

Oil Screw Conveyor is mainly used to transport various types of oil. This includes but is not limited to liquid grease, viscous oil, and oil containing a small amount of solid particles. Its core function is to transfer oil from one location to another, such as from a storage tank to a processing equipment, or to transfer materials between different process units. The equipment can achieve horizontal, inclined, or short-distance vertical transportation. During the transportation process, its closed design effectively controls the spillage and volatilization of oil, which is helpful in keeping the operating environment clean and avoiding material loss. At the same time, it can isolate external impurities to ensure that the transported oil remains in its original state, meeting the requirements for purity. Its applications are wide and diverse, mainly reflected in industrial scenarios where various oily or oil-containing materials need to be handled safely and hygienically. For example, in the extraction, filtration, refining and packaging of edible oil, vegetable oil and animal oil, it is used to transport crude oil, refined oil, filter cake, oil residue, etc. between different processes. In biodiesel production, it transports raw oil, reaction products, etc. It transports oil from storage tanks to mixing, filling or packaging equipment. In refineries, it handles and transports various types of crude oil, refined petroleum products, and sludge and oil residue generated during the refining process. It is used to transport cooking oil, seasoning oil, liquid additives and other oily ingredients, such as in baking, frying, filling and packaging lines.

The design features of Oil Screw Conveyor are mainly reflected in the closed transportation of oil, which helps to control the volatilization and spillage of materials and reduce the potential impact of external impurities on oil. The structure of the equipment is relatively compact, which is convenient for material transfer in a limited space. At the same time, according to the viscosity and solid particle content of different oils, by adjusting the spiral blades and internal structure, a relatively stable operation can be achieved.