Concrete Screw Conveyor

The price of Concrete Screw Conveyor varies significantly, ranging from US$200 to US$8,000 or even higher, depending on its model, material, and customization requirements.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

What is Concrete Screw Conveyor?

Concrete Screw Conveyor is a key tool for handling various bulk materials. It is mainly responsible for materials such as cement, fly ash, mineral powder, sand and gravel aggregates, and semi-dry concrete. This equipment has many advantages in the material transportation process, such as its compact structure, which can adapt to relatively limited installation space; good sealing, which helps to reduce dust in the working environment and reduce material loss during transportation; at the same time, its transportation process is relatively stable, which helps to maintain the uniformity of the material. This type of equipment has different levels of processing capacity, which can meet the needs from precise supply of small amounts of materials to continuous large-scale material transfer. The conveying distance of a single machine is usually within a few dozen meters, which can be adjusted and deployed according to the actual situation on site.

What are the advantages of Concrete Screw Conveyor?

Concrete Screw Conveyor has many advantages due to its unique design and operation mode. It is different from traditional belt conveyors or pumping equipment, and can push materials forward in a specific way in a relatively closed environment. It has the following main advantages:

Compact structure and small footprint: Concrete Screw Conveyor adopts tubular or U-shaped trough body, which contains spiral blades inside, and the overall structure is relatively compact. This allows it to be flexibly arranged on construction sites or production lines with limited space, effectively saving valuable working space.

Good sealing and reduced dust: The tubular screw conveyor is a fully enclosed design, which can effectively prevent concrete dust from flying during transportation. At the same time, the closed conveying avoids the scattering and loss of materials during transportation, ensuring the integrity and transportation efficiency of the materials.

Stable transportation, materials are not easy to segregate: The screw conveyor pushes the concrete through the continuous rotation of the spiral blades, and the conveying process is smooth. This conveying method helps to reduce the segregation phenomenon that may occur during the conveying process of concrete and maintain the uniformity of concrete.

Multi-angle conveying can be achieved: In addition to horizontal conveying, Concrete Screw Conveyor can also be conveyed at an angle. This allows it to adapt to construction needs of different heights and spatial layouts, such as conveying concrete from the ground to a mixing plant or a high pouring point, increasing the versatility of the equipment.

Suitable for various forms of concrete and related materials: Concrete Screw Conveyor is not only suitable for dry powdered cement, sand and gravel aggregates, but also commonly used to convey materials with poor fluidity such as semi-dry hard concrete. The special design of its spiral blades can effectively push such materials and avoid blockage.

Parameters of Concrete Screw Conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

How does a concrete screw conveyor work?

A concrete screw conveyor, also known as an auger conveyor, is a device that uses the continuous rotation of spiral blades to transport materials. Its operating principle can be summarized in several key steps. First, the spiral blades rotate. The core component of a concrete screw conveyor is a rotating shaft with spiral blades. When a motor drives this shaft through a reducer, the spiral blades begin to rotate within a fixed tubular or U-shaped trough. This continuous rotation provides the primary motive force for material movement. Second, the material is filled and subjected to force. At one end of the conveyor, usually at the lower feed inlet, concrete or other materials to be conveyed are loaded into the trough. Under the influence of gravity, the material fills the spaces between the spiral blades. As the blades begin to rotate, they continuously exert a thrust on the material. Finally, there is the axial movement of the material. The material's movement within the screw conveyor is primarily forward, not rotational, but rather along the screw shaft. This is due to friction between the material and the conveyor trough. As the spiral blades push the material, it is simultaneously subjected to axial thrust from the blades and radial friction from the trough. This friction prevents the material from rotating with the blades, forcing it to move forward axially. Finally, the material is continuously conveyed and unloaded. Because the spiral blades rotate continuously, the material is continuously pushed from the inlet to the outlet at a steady rate. When the material reaches the other end of the conveyor, the outlet, it is unloaded due to gravity or by the blades. The entire process is continuous and uninterrupted, ensuring a stable supply of materials such as concrete and dry powder. In short, the concrete screw conveyor uses the rotating spiral blades to cleverly utilize the friction between the material and the trough to continuously and stably transport the material from one point to another. It is particularly suitable for conveying concrete and dry powder materials, which require high sealing properties.

What are the structural features of a concrete screw conveyor?

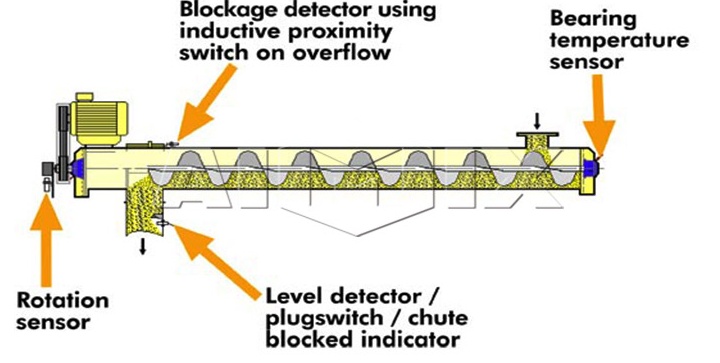

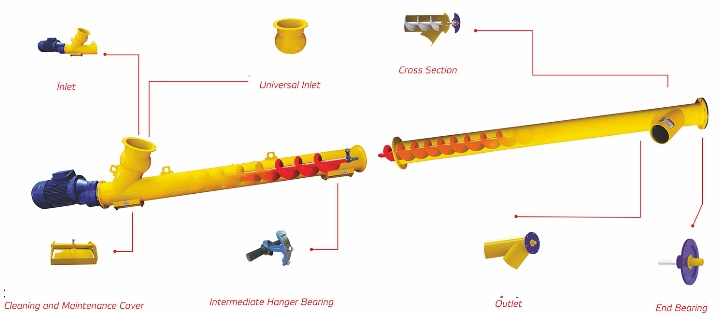

A concrete screw conveyor, commonly known as an "auger conveyor," uses rotating spiral blades to transport materials such as concrete, cement, and fly ash. Its structure is compact and relatively simple, consisting primarily of the following core components:

Screw blades and screw shaft: These are the conveyor's core working components. The spiral blades are helically wound around a central shaft. As the shaft rotates, the blades propel the material forward. Depending on the design, the spiral blades can be continuous or segmented. The screw shaft provides support and a path for the blades' rotation.

Casing: The casing is the outer structure that encloses the spiral blades and shaft, typically in the form of a tube or U-shaped trough. Tubular casings offer excellent sealing properties, effectively preventing dust and material leakage, making them particularly suitable for conveying materials with high sealing requirements, such as cement and fly ash. U-shaped trough casings facilitate inspection and cleaning, making them suitable for conveying sticky or easily agglomerated materials, but offer less sealing properties.

Drive: The drive provides power to the conveyor and typically consists of an electric motor and a reducer. The motor provides high-speed power, which the speed reducer converts into low-speed, high-torque to drive the screw shaft.

Inlet and outlet: These are the channels through which material enters and exits the conveyor. The inlet, typically located at one end of the conveyor, receives material from a silo or other equipment; the outlet, located at the other end, unloads material to a designated location.

Bearings: Bearings are critical components that support the screw shaft, ensuring smooth and reliable rotation. Depending on the conveyor design and length, bearings are typically located at either end or in the middle of the screw shaft to reduce friction and wear.

What is the price of Concrete Screw Conveyor?

The price of Concrete Screw Conveyor is a relatively wide range because it is significantly affected by many factors. Generally speaking, its price may range from US$200 to US$8,000, or even higher, depending on its specifications and configuration. The price of Concrete Screw Conveyor is affected by many factors. First of all, the model and specifications are the key to determining the price, including the screw diameter (the larger the diameter, the stronger the conveying capacity and the higher the price), the conveying length (the longer the equipment, the higher the cost) and the conveying angle (vertical or large-angle conveyors are usually more expensive than horizontal models due to their more complex structures). Secondly, the material selection is also directly related to the cost. Standard equipment mostly uses carbon steel, which is relatively cheap. If you need to improve wear resistance or cope with special applications, the selection of stainless steel or wear-resistant materials will significantly increase the investment. In addition, the configuration of the drive system also affects the price. The larger the motor power or the choice of a well-known brand and high-efficiency reducer, the higher the cost. The complexity of the automation and control system is also a consideration. From basic start-stop functions to advanced configurations such as variable frequency speed regulation and remote control, there will be price differences. Finally, customized requirements also push up prices. For example, special inlet and outlet designs, structures that are easy to clean and maintain, or equipment that meets special environmental requirements such as explosion-proof and high temperature resistance all require additional design and manufacturing costs.

What are the applications of Concrete Screw Conveyor?

As a material conveying equipment, Concrete Screw Conveyor has a wide range of application scenarios, spanning the needs of bulk material conveying in multiple industrial fields. Its core function is to stably transfer various powdered, granular and semi-fluid materials, especially when handling cement, sand, fly ash, mineral powder and other components closely related to building materials, it shows unique advantages. This type of conveyor is often used for the precise supply of raw materials. Whether it is conveying bulk cement and fly ash from large silos to metering equipment, or conveying fine aggregates from storage tanks to mixing machinery, screw conveyors can ensure the continuous and controllable supply of materials, laying the foundation for subsequent production or construction links. Secondly, it plays an important role in the transfer and distribution of materials. In the production process, Concrete Screw Conveyor can transport mixed dry powder or semi-finished materials from one process point to the next processing equipment. For example, conveying pre-mixed dry mortar to the packaging area, or transferring fresh concrete from the mixer to the forming mold, its airtightness effectively prevents dust or spillage of materials during the transfer process, improving the cleanliness of the working environment. In addition, the equipment is also suitable for the lifting of specific materials. When the production line needs to transport materials from the lower ground to the storage tank or processing equipment at a higher position, the inclined or vertical Concrete Screw Conveyor can achieve efficient vertical or large-angle transportation, effectively utilize space and simplify material flow lines. In some links that require precise batching or have strict requirements on material uniformity, the screw conveyor can maintain the uniformity of the material to a certain extent and reduce the occurrence of segregation through its unique conveying method.

Concrete Screw Conveyor Cases

Concrete Screw Conveyor is widely used in construction, building materials and related industries. It is mainly used to transport various forms of concrete materials and bulk raw materials such as cement, fly ash, mineral powder, sand and gravel aggregates. In a concrete mixing plant, the screw conveyor is an important link between each material silo and the mixing host. For example, the bulk cement in the silo is accurately transported to the metering hopper or mixer. In some cases, especially for fine aggregates (such as sand), the screw conveyor can also be used to transport from the silo to the batching system. In ready-mixed concrete plants, screw conveyors are used to transfer fresh concrete, especially in precast concrete production. They can transport fresh concrete from forced mixers to various molds. Compared with belt conveyors, they can better prevent concrete from segregation during transportation and maintain the uniformity of materials. In addition, screw conveyors are also widely used in dry mortar production. Convey various dry powdered raw materials such as cement, sand, additives, etc. from their respective silos to mixers for proportioning and mixing. Convey the mixed dry mortar to packaging machines or bulk tanks. In certain links of construction waste recycling and treatment, screw conveyors can be used to transport separated fine aggregates or powdered waste. For some concrete with special formulas, poor fluidity or specific requirements for the conveying process, screw conveyors can provide a more stable conveying method. In general, Concrete Screw Conveyor has become a reliable choice for handling cement, fly ash, and various dry powder and semi-dry hard concrete materials due to its good airtightness, stable conveying, and compact structure.

Concrete Screw Conveyor has become an indispensable equipment in construction and related fields due to its inherent characteristics in material transportation. It can complete the transfer task of powder, granular and some semi-fluid materials in a relatively controlled environment. The selection and configuration of the equipment needs to be determined based on the specific material characteristics, the required conveying volume, the spatial conditions on site and the requirements for material uniformity. By selecting the appropriate screw diameter, length, material and drive mode, this type of conveyor can be reliably integrated into the existing production process or construction plan to provide a stable material conveying path.

Q: What is the maximum conveying distance of a concrete screw conveyor?

A: The effective conveying distance of a single screw conveyor is typically in the tens of meters. For example, some equipment can be designed to reach around 25 meters.

Q: What is the price of a concrete screw conveyor?

A: The price ranges from US$200 to US$8,000.