Cement Screw Conveyor

The price of Cement Screw Conveyor varies depending on factors such as model, material, and the price usually ranges from US$200 to US$4,000.

Rotation speed: 45-70 R/Min

Size (L*W*H): 2000*200 * 220mm/customizable

Frame material: carbon steel/stainless steel

Power: 0.4kW-22kW

Voltage: 220V/380V/415V

Frequency: 50/60Hz

What is Cement Screw Conveyor?

Cement Screw Conveyor is a device used to transfer powdered materials such as cement, fly ash, and mineral powder in various industrial environments. This type of conveyor is mainly based on a tubular shaft structure to adapt to the characteristics and transportation needs of cement. In terms of material handling capacity, Cement Screw Conveyor can handle several tons to hundreds of tons of cement per hour according to the model configuration. The conveying distance of a single device usually ranges from several meters to tens of meters. For example, a specific configuration can achieve vertical lifting of more than 20 meters, or horizontal conveying of up to 60 meters, providing a mechanical means for the continuous transfer of powdered materials.

Cement screw conveyors typically utilize flange connections, ensuring tightness and stability between devices and interfaces with silos and bins, facilitating quick installation and maintenance. In practical applications, the linkage of multiple devices is a common configuration. Multiple screw conveyors can be connected in series or parallel to meet production line requirements, creating an automated conveying system for long-distance, multi-point material loading and unloading. The inclination angle of a cement screw conveyor typically ranges from 0 to 45 degrees, depending on the material characteristics and conveying distance. Inclined conveying effectively utilizes space and reduces footprint. Overall, cement screw conveyors, with their compact structure, excellent sealing, and ease of operation, play an important role in material handling in the cement industry.

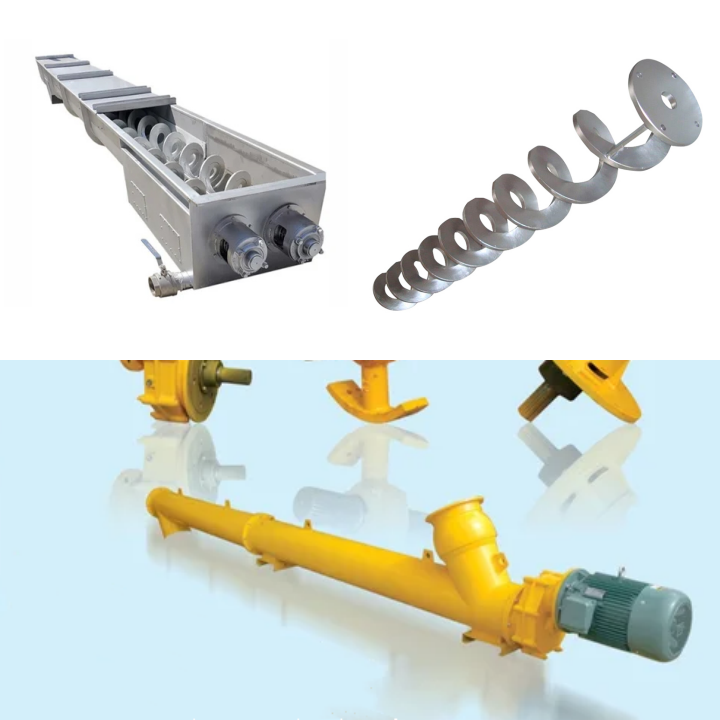

What are the types of Cement Screw Conveyor?

Cement Screw Conveyor is a device used to convey powdered materials such as cement, fly ash, and mineral powder. Its main types are usually divided around the casing form and spiral structure. The common and suitable type is the tubular shaft screw conveyor. This combination makes full use of the advantages of the closedness of the tubular type to control dust and moisture, while using the stability and reliability of the shaft screw to effectively convey cement, a powdered material with good fluidity but high specific gravity.

Features: The most common form of Cement Screw Conveyor is the tube type. The spiral blades are completely enclosed in a circular tubular casing.

Applicability: This is the main type of cement conveying. Its excellent airtightness can effectively prevent cement dust from spilling out, avoid polluting the environment and wasting materials. At the same time, it can also prevent external moisture from entering, keep the cement dry, and avoid moisture and agglomeration. The tubular structure also enables it to adapt to horizontal, inclined, and even vertical conveying at a certain angle.

Features: The spiral blades rotate in a U-shaped or O-shaped open trough body, and a cover plate is usually added to the top for sealing.

Applicability: Although it can also be used for cement conveying, its airtightness is usually slightly inferior to that of the tube type. If dust control and moisture resistance are required, the tube type is more suitable. The trough screw conveyor may be more convenient than the tube type in terms of maintenance and cleaning.

Features: The spiral blades are welded on a solid or hollow central shaft, and the blades are driven to convey materials through the rotation of the central shaft.

Applicability: This is the standard configuration of Cement Screw Conveyor. Cement has relatively good fluidity, and the shaft structure can provide stable thrust to ensure continuous transportation. Although cement has a certain degree of abrasiveness, the structural strength of the shaft screw is usually sufficient to cope with it. A hanging bearing may be required in the middle to support the long-distance screw shaft.

Features: There is no central shaft, only a flexible screw body rotates in the trough or special tubular shell.

Applicability: The shaftless screw is mainly designed to convey materials with strong viscosity, easy to entangle, easy to agglomerate or containing large pieces of debris (such as sludge, grid slag, etc.). Its main advantage is to avoid entanglement and blockage. Cement is a fine powder material. During the operation of the shaftless screw, the material may idle or the efficiency may decrease during the rotation of the screw. In addition, the structural strength of the shaftless screw is usually not as good as that of the shafted screw, which is suitable for conveying cement with a larger specific gravity.

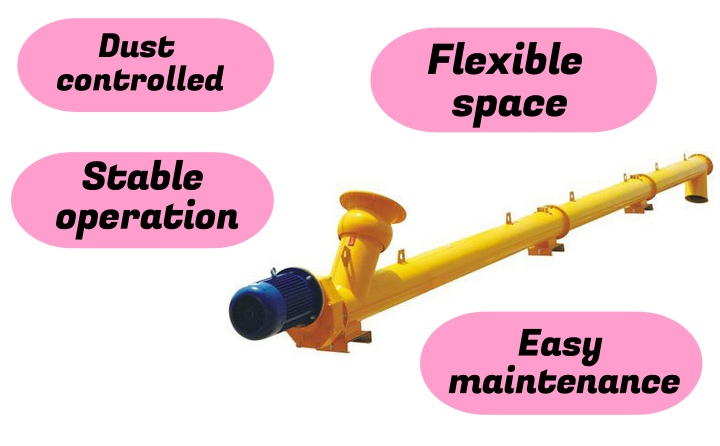

What are the advantages of Cement Screw Conveyor?

Cement Screw Conveyor has multiple advantages in the transportation of cement and similar powdered materials, which are mainly reflected in its effective control of dust, stable operation, flexible space utilization and long-term durability of the equipment.

Control dust and moisture: The tubular structure ensures that the cement is completely enclosed in the pipe during transportation. This means that cement dust will not fly into the environment, effectively avoiding air pollution, improving the visibility and breathing environment of the working area, and reducing material loss. At the same time, this airtightness can effectively isolate external moisture and prevent cement from getting damp and agglomerating, thereby ensuring the quality of cement and the smoothness of subsequent processes.

Stable and reliable transportation process: The shafted spiral design provides strong support and stable propulsion for cement transportation. The spiral blades are firmly fixed on the central axis, which can continuously and evenly push cement powder, and maintain a consistent material flow even in long-distance or certain inclination angle transportation tasks. This design reduces the possibility of material fluctuations or interruptions during operation and ensures the continuity of the production process.

The equipment structure is sturdy and durable: Cement has a certain degree of abrasiveness, which will cause wear to the conveying equipment. Cement Screw Conveyor is usually made of high-strength materials, such as high-quality steel, and the edge of the spiral blade can also be hardened to enhance its wear resistance. This sturdy structure enables the equipment to withstand the specific gravity and friction of cement for a long time, extending the service life of the equipment and reducing the frequent replacement of parts and downtime maintenance caused by wear.

Flexible and diverse space utilization: Cement Screw Conveyor can flexibly achieve horizontal, inclined and even a certain degree of vertical transportation according to actual site requirements. This means that whether it is inside a crowded factory or at a work point where cement needs to be lifted to different heights, this conveyor can find a suitable installation solution, effectively saving valuable ground space and optimizing the path of materials from the silo to the mixer or packaging line.

Cement Screw Conveyor Parameters

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

DIMENSIONAL TABLE

| LENGHT | 4 INCH 114 | 5 INCH 139 | 6 INCH 168 | 8 INCH 219 | 10 INCH 273 | 12 INCH 323 |

| 1 MT | 1,5 KW | 1,5 KW | 2,2 KW | 5,5 KW | 5,5 KW | 7,5 KW |

| 2 MT | 1,5 KW | 2,2 KW | 3,7 KW | 5,5 KW | 7,5 KW | 9,5 KW |

| 3 MT | 1,5 KW | 2,2 KW | 3,7 KW | 5,5 KW | 7,5 KW | 9,5 KW |

| 4 MT | 1,5 KW | 2,2 KW | 3,7 KW | 7,5 KW | 7,5 KW | 11 KW |

| 5 MT | 1,5 KW | 3 KW | 5,5 KW | 7,5 KW | 11 KW | 11 KW |

| 6 MT | 1,5 KW | 4 KW | 5,5 KW | 7,5 KW | 11 KW | 15 KW |

| 7 MT | 2,2 KW | 4 KW | 5,5 KW | 11 KW | 15 KW | 15 KW |

| 8 MT | 2,2 KW | 4 KW | 5,5 KW | 11 KW | 15 KW | 18,5 KW |

| 9 MT | 2,2 KW | 4 KW | 5,5 KW | 1,1 KW | 18,5 KW | 18,5 KW |

| 10 MT | 3,7 KW | 5,5 KW | 7,5 KW | 11 KW | 18,5 KW | 22 KW |

| 11 MT | 3,7 KW | 5,5 KW | 7,5 KW | 15 KW | 18,5 KW | 22 KW |

Cement Screw Conveyor Reducer

| POWER | TYPE | SHAFT DIAMETER | FLANGE DIAMETER B5 |

| 2,2 KW-1500 | 100 | 28 MM | 250 MM |

| 3 KW- 1500 | 100 | 28 MM | 250 MM |

| 4 KW- 1500 | 112 | 28 MM | 250 MM |

| 5,5 KW-1500 | 132 | 38 MM | 300 MM |

| 7,5 KW-1500 | 100 | 28 MM | 250 MM |

| 11 KW- 1500 | 160 | 42 MM | 350 MM |

| 15 KW- 1500 | 160 | 42 MM | 350 MM |

| 18,5 KW- 1500 | 180 | 48 MM | 350 MM |

| 22 KW- 1500 | 180 | 48 MM | 350 MM |

| 30 KW- 1500 | 200 | 55 MM | 400 MM |

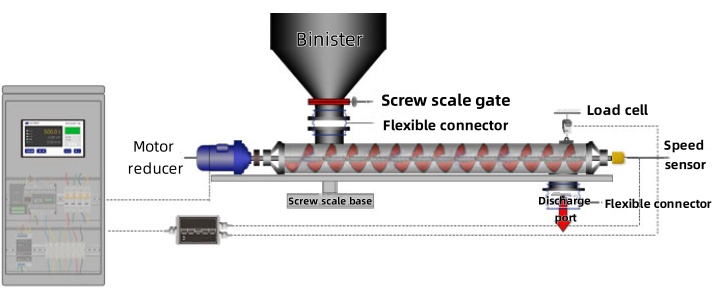

How does a cement screw conveyor work?

The operating principle of a cement screw conveyor is based on the mechanism of a rotating screw body propelling the material. Its core component is a screw shaft with spiral blades mounted within a U-shaped or circular closed trough. When a motor drives the screw shaft, the spiral blades fixed to the shaft rotate accordingly. Due to the material's own gravity and the frictional resistance of the trough wall, the material does not rotate with the spiral blades. Instead, it is driven forward in the direction of the spiral blades by the normal thrust of the spiral surface. Simply put, it can be imagined as a continuously rotating "screwdriver" that continuously "drills" into the cement material within the trough and pushes it from the inlet to the outlet. This conveying method is characterized by continuous conveying, with the continuous rotation of the spiral blades ensuring continuous and uniform material transportation. The well-sealed, closed trough structure effectively prevents the leakage of cement dust, reducing environmental pollution and material loss. Compared to other conveying equipment, screw conveyors are compact and require less floor space, making them easy to deploy in confined spaces. In addition to horizontal conveying, screw conveyors can also be tilted within a certain angle (usually 0-45 degrees) to accommodate various production line layout requirements.

What are the applications of Cement Screw Conveyor?

Cement Screw Conveyor is a device designed for handling fine powdered materials such as cement, fly ash, and mineral powder. It has a wide range of applications, mainly focusing on scenarios that require closed, continuous and precise conveying of powdered building materials. For example, concrete mixing plants are the core application scenarios of Cement Screw Conveyor. In concrete mixing plants, it undertakes the key task of conveying cement and fly ash from the bottom of their respective silos to the mixer or metering hopper. Its airtightness effectively prevents dust from spilling and materials from getting wet, ensuring the accuracy of ingredients and the cleanliness of the environment. Inside the cement plant, Cement Screw Conveyor is used to convey finished cement after cement clinker grinding. It can convey finished cement from the mill to the cement silo for storage, or from the bottom of the silo to the bulk cement loading system, and load the cement into bulk cement tankers for transportation. In the production line of dry mortar and premixed mortar, Cement Screw Conveyor is used to accurately transport powdered aggregates such as cement, lime powder, gypsum powder, etc. from the silo to the mixer for batching. This ensures the accuracy of the formula of dry mortar products and the continuity of the production process. Cement Screw Conveyor is also often used as an auxiliary feeding or quantitative feeding device for other equipment. For example, it can be integrated with the weighing system to achieve accurate metering of cement to meet the strict control of the material feed amount in the downstream process. In some special cases, it can also be used for preliminary mixing or temperature adjustment of cement during the conveying process (if a special jacket is designed). In general, Cement Screw Conveyor is a basic equipment to ensure the safe transportation of powdered materials in the fields of construction, building materials and related industries.

Cement Screw Conveyor Manufacturers

Cement screw conveyor manufacturers typically offer comprehensive service capabilities, from design and manufacturing to installation and commissioning. In addition to standard models, manufacturers can provide customization capabilities based on specific working conditions and material characteristics. This includes adjusting the various parameters of the screw conveyor according to factors such as the customer's conveying volume requirements, conveying distance, material abrasiveness, humidity, temperature, and site space limitations. For example, for highly abrasive materials, manufacturers will use special wear-resistant materials to manufacture spiral blades and troughs; for scenarios that require precise metering or to prevent material compaction, a variable frequency speed regulation system may be integrated or an arch-breaking device may be added; when dealing with different inclination angles, the spiral pitch and bearing support structure will be optimized to ensure stable and reliable operation. Factors to consider when selecting include but are not limited to: the bulk density, particle size, moisture content, viscosity, and abrasiveness of the material; the length and inclination angle of the conveyor; the required conveying volume; the feeding and discharging methods (such as multi-point feeding and multi-point discharging); and the on-site environmental conditions (such as explosion-proof, dust-proof, and corrosion-resistant). Manufacturers will provide a variety of combinations of different diameters, lengths, spiral pitches, drive powers and trough forms (such as U-shaped grooves and round tubes) to ensure that the equipment performance is precisely matched with actual needs and avoid inefficiency or operational failures caused by improper selection.

What are the prices of Cement Screw Conveyor?

The price of Cement Screw Conveyor is affected by many factors, forming a price range from US$200 to US$4,000 or even higher. First of all, the model and specification are the direct factors affecting the price. The larger the diameter of the screw, the higher the required materials and manufacturing costs, the higher the conveying capacity, and the higher the price. Similarly, the longer the conveying length, the greater the investment in the casing, screw body, support structure and drive device. In addition, the increase in conveying capacity usually means the need for a larger diameter screw and a stronger drive system, which in turn pushes up the overall cost. If the conveyor needs to be transported at a large angle or vertically, its structural design will be more complicated and the demand for drive power will be higher, which will be directly reflected in the price. Secondly, the choice of material has a significant impact on the cost. Most Cement Screw Conveyors are made of carbon steel, which makes them relatively low in price. However, if the application scenario has special requirements for corrosion protection, or needs to convey other powders with high cleanliness standards, the use of stainless steel (such as 304 or 316L) will greatly increase the cost, because stainless steel itself is more expensive and the processing technology is more complicated. In addition, the configuration of the drive system is another key factor. The size of the motor power directly determines the cost of the motor and reducer. The greater the power, the higher the price. More importantly, if there is a risk of dust explosion in the working environment, explosion-proof motors and explosion-proof control systems must be equipped, which will significantly increase the overall cost of the equipment. Finally, structural details and degree of customization will also directly affect the final quotation. For example, special inlet and outlet sizes, shapes or multi-point inlet and outlet designs all require additional customization costs. Wear-resistant treatment for the abrasiveness of cement (such as spiral blade surfacing or lining), as well as customized leg height, material or support structure according to on-site installation requirements, will increase manufacturing costs. In addition, if the conveyor is integrated with special functions such as heating/cooling jackets, weighing modules, cleaning devices or automatic control systems, the total price will also increase.

The structural design of Cement Screw Conveyor focuses on the dust characteristics of cement and the requirements for a dry environment. It usually adopts a closed structure and wear-resistant materials to maintain the stable operation of the equipment. Its advantage lies in its ability to provide a closed conveying environment, which helps control dust diffusion and maintains the dry state of the material. At the same time, its shaft structure gives the equipment stable thrust and bearing capacity, allowing powdery materials such as cement to be transferred continuously and smoothly. These features make it a practical tool for conveying cement and similar powders.