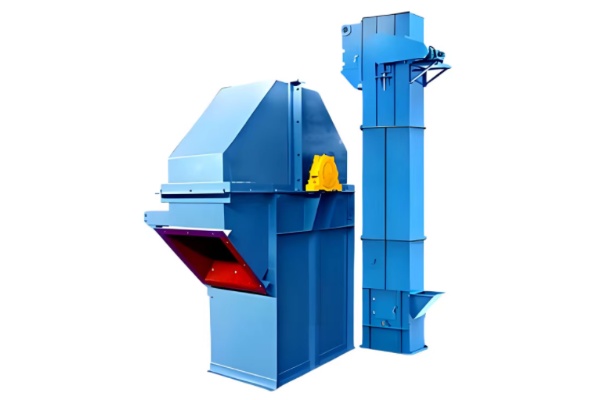

Belt Type Bucket Elevator

The price of belt type bucket elevator varies depending on factors such as model, lifting height, conveying volume and material, and usually ranges from $350 to $7,000.

Power: 750 watts

Dimensions: 2100x730x2350mm/customizable

Width or diameter: 500mm/customizable

Voltage: 220/380V

Bucket volume: 0.15

Lifting height: 1.9 meters

What is Belt Type Bucket Elevator?

Belt Type Bucket Elevator is a vertical conveying equipment used to transfer bulk materials from low to high. The equipment mainly carries materials through a bucket fixed on a continuously running belt to achieve vertical displacement. According to the material characteristics and conveying requirements, buckets can be divided into deep buckets and shallow buckets. Deep buckets are usually suitable for small particles with good fluidity, while shallow buckets are mostly used to handle blocky or viscous materials. In practical applications, this type of elevator can achieve a lifting height of tens of meters or even hundreds of meters. The processing capacity of a single device is usually between several tons and hundreds of tons per hour, depending on factors such as bucket size, belt speed and material density.

When choosing the appropriate belt type bucket elevator, it is necessary to comprehensively consider the characteristics of the conveyed material (such as particle size, density, abrasiveness, temperature, fragility), the required conveying capacity and lifting height, and the specific working conditions on site. Among them, stainless steel hoppers are mainly suitable for occasions with strict requirements on hygiene, corrosion resistance, high temperature or high strength; while plastic hoppers have advantages in light weight, corrosion resistance, low noise, no sparks and hygiene. The choice of deep hopper and shallow hopper mainly depends on the fluidity, particle size and conveying volume requirements of the material.

What are the types of Belt Type Bucket Elevator?

Belt type bucket elevators are mainly classified according to the material of their hoppers.The material and shape of the bucket of a belt bucket elevator determine its application range. They are designed with deep and shallow buckets to meet the conveying requirements of different materials. Common types include stainless steel hoppers and plastic hoppers. They each have unique advantages to suit the specific needs of different industries.The following are their main types:

Stainless steel hopper belt type bucket elevatorStainless steel hoppers are usually used in places with high requirements for hygiene, corrosion resistance or high temperature environments. Stainless steel materials (such as 304, 316L, etc.) have excellent corrosion resistance, high temperature resistance and easy cleaning. Among them, the deep bucket type is mainly suitable for conveying materials with poor fluidity, block or large particle size. The design of the deep bucket helps to improve volume utilization and reduce material scattering. The shallow bucket type is mainly suitable for conveying materials with good fluidity, powder, small particles or easy to throw. The shallow bucket facilitates the smooth dumping of materials. The conveying capacity depends on the volume, quantity, running speed and material characteristics of the bucket, which can range from a few tons to hundreds of tons per hour.

Plastic hoppers are usually made of high-strength engineering plastics (such as HDPE, nylon, polyurethane, etc.) to make hoppers, with rubber or PVC belts. This type of elevator has significant advantages in certain specific applications. The deep bucket type is suitable for conveying less abrasive, lumpy or large-sized materials. It has advantages in situations where noise reduction, wear on equipment or metal contamination need to be reduced. The shallow bucket type is suitable for conveying materials with good fluidity, powder, small particles or easy to throw. It is especially suitable for industries that require high cleanliness and no pollution. Similar to the stainless steel deep bucket type, depending on the size, number and running speed of the bucket, but due to the load-bearing limit of the plastic material, its maximum conveying capacity may be slightly lower than that of the stainless steel bucket of the same specification.

What are the advantages of Belt Type Bucket Elevator?

Belt Type Bucket Elevator occupies an important position in the vertical transportation of bulk materials, which is mainly attributed to its many advantages. First of all, it has a strong conveying capacity, fast belt traction speed, and with a large-capacity hopper, it can transport a large amount of materials per unit time, ensuring the stable material supply of high-yield industrial production lines. Secondly, the lifting height of the belt elevator, its high-strength belt can withstand tension. In terms of operation, it exhibits the characteristics of stability and low noise. Compared with the chain elevator, the flexibility of the belt effectively reduces the impact on the drum, reduces vibration and noise, and also reduces the impact of equipment startup and operation on the drive system. The equipment has little wear on the material and has a wide range of applications. The flexibility of the belt and the throwing action during centrifugal unloading can effectively reduce the friction and impact between the material and the equipment, and reduce the breakage rate of fragile materials. It can widely transport various powdery, granular and small-block bulk materials, such as grains, cement, ore, coal, fertilizers and feed. In terms of maintenance, the belt elevator is relatively simple to maintain and has a long life. Belts usually have a long service life and only require regular inspection and maintenance. Compared with chain type, it has fewer problems with bearing and chain wear, which reduces maintenance workload. Some designs can also achieve quick replacement of belts and hoppers, reducing downtime.

How does a Belt Type Bucket Elevator work?

A Belt Type Bucket Elevator is a device that uses a series of buckets fixed to a rubber or fabric belt to lift bulk materials vertically through continuous motion. Its working principle can be broken down into the following main steps:

Feeding: Material enters the elevator frame at the bottom of the elevator from the bottom or feed port. Here, the bucket will "scoop" or "scoop" the material from the material at a high speed. There are usually two types of feeding methods, scooping feeding, where the bucket scoops directly from the accumulated material; and continuous feeding, where the material enters the bucket continuously, usually through a chute or other feeding device.

Lifting: The bucket filled with material runs vertically upward along the lifting section of the elevator. The belt is driven by a top drive device (usually a motor and reducer) and maintained at the appropriate tension by a bottom tensioning device. The bucket lifts the material upward at a certain speed evenly.

Discharging: When the bucket reaches the top of the elevator, the belt passes over a head roller. Due to centrifugal force, gravity and the geometry of the bucket, material is thrown out of the bucket and falls into the discharge chute or outlet. For high-speed elevators, centrifugal force is the main discharge method; for low-speed elevators, gravity is more prominent.

Return: The empty bucket continues to move downward with the belt and returns to the bottom of the elevator, ready to be reloaded with material, completing a cycle.

Basic parameters of Belt Type Bucket Elevator

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

What are the differences between a belt type bucket elevator and a chain bucket elevator?

Belt type bucket elevators and chain bucket elevators are two common vertical conveying equipment used to lift bulk materials to heights. While they function similarly, they differ significantly in structure, performance, and application.

Differences in Traction Components: The primary traction component of a belt type bucket elevator is a high-strength rubber or canvas belt. These belts are typically constructed from multiple layers of fiber fabric or steel cord, and are characterized by their light weight, smooth operation, and low noise. The main traction element of a chain bucket elevator is an endless chain, typically a leaf chain or bushing roller chain. Made of metal, the chain is sturdy and can withstand greater tension.

Conveying Capacity and Adaptability: Belt type bucket elevators are suitable for conveying materials with low abrasiveness, low density, and low temperatures, such as grain, feed, and fertilizer. Due to the limited load-bearing capacity of the belt, their conveying capacity is relatively small, but their high operating speed allows for higher conveying capacity. Chain bucket elevators are suitable for conveying materials with high abrasiveness, high density, and high temperatures, such as ore, coal, and cement clinker. The chain's high strength allows it to withstand greater shock and load, resulting in a higher conveying capacity, but the operating speed is generally lower.

Maintenance and Service Life: The belt's good elasticity absorbs shocks, minimizing damage to the material and the equipment itself. However, it is susceptible to high temperatures and chemical corrosion and requires regular inspection and replacement. Chains are made of metal and are wear-resistant, heat-resistant, and corrosion-resistant, generally resulting in a longer service life. However, chains can produce noise during operation and require regular lubrication and tension adjustment. Drive Type: Belt type bucket elevators typically use a top-drive mechanism, with the belt driven by a drive roller. This structure is simple and offers high transmission efficiency. Chain bucket elevators offer a wider variety of drive options, with options for top-drive or bottom-drive depending on specific needs.

What are the applications of Belt Type Bucket Elevator?

As a vertical conveying equipment, Belt Type Bucket Elevator is mainly used to lift various types of bulk materials from a lower position to a higher position. Its application range is wide and not limited to specific industries or fields. It is mainly reflected in the following aspects:

Material transfer: The core function of the equipment is to transfer powder, granular and small block materials by height difference. This includes receiving materials from the ground and lifting them to high-level silos, or conveying materials from one low-level process to the next high-level process between different processing units. For example, conveying from an underground receiving pit to an above-ground storage facility, or lifting from the outlet of a mixer to the inlet of a packaging machine.

Material conveying: Because it usually adopts a fully enclosed casing structure, the Belt Type Bucket Elevator can effectively control dust and material spillage during the conveying process. This is especially suitable for places where materials need to be handled under clean or specific environmental conditions, helping to keep the work area clean.

Feeding or loading at high places: Belt Type Bucket Elevator plays an important role in scenarios where large amounts of bulk materials need to be lifted to a higher platform for feeding or loading. For example, high-level loading to tall reactors, mixing equipment or transport vehicles (such as train cars, trucks).

Buffering and pre-storage transfer of lifted materials: In some cases, bucket elevators are also used to lift materials to buffer bins or pre-storage areas. It serves as the first step in the flow of materials to the storage system to ensure that the materials can smoothly enter the subsequent storage or distribution links.

Belt Type Bucket Elevator Cases

Belt Type Bucket Elevator is mainly used for vertical transportation of bulk materials. From mines to factories, from ports to granaries, various powdered, granular, and small block materials play a pivotal role. In the building materials industry, it is widely used for the lifting of powdered and block materials such as cement, limestone, clinker, and gypsum. In the grain and food processing industry, Belt Type Bucket Elevator is an ideal choice for vertical transportation of grains, corn, wheat, rice, and various food raw materials. Mining and metallurgical industries are also important application areas. The lifting demand for bulk materials such as coal, ore, and coke is large. Belt Type Bucket Elevator can withstand large loads and adapt to harsh working environments, providing reliable guarantees for mineral mining and smelting. Belt Type Bucket Elevator has shown its strong adaptability in bulk cargo loading and unloading at port terminals, conveying fertilizers and plastic granules in the chemical industry, and conveying ash and slag in the power industry. In summary, Belt Type Bucket Elevator has become the preferred equipment for vertical transportation of bulk materials due to its simple structure, smooth operation, large conveying capacity, high lifting height and easy maintenance.

Belt Type Bucket Elevator Manufacturers

Belt Type Bucket Elevators have a wide range of applications, but the equipment requirements vary significantly across different production environments. Therefore, a manufacturer's customization capabilities are a key indicator of their technical strength and service level. Manufacturers are able to tailor solutions to each customer's specific operating conditions. Customization is primarily reflected in the adjustment of equipment parameters. This includes matching the appropriate hopper capacity, conveyor belt width, and operating speed based on material characteristics such as bulk density, particle size, temperature, and abrasiveness. For example, for applications handling highly abrasive ores, manufacturers may recommend a more wear-resistant rubber belt and a thicker steel hopper. For applications in the food or chemical industry handling fragile, lightweight materials, a lighter plastic hopper and lower operating speeds may be used to minimize material breakage. Customization is also reflected in the structural design. Manufacturers can adjust the elevator's overall height, footprint, and inlet and outlet locations based on site space constraints. In certain special operating conditions, such as high temperatures or corrosive environments, manufacturers may use high-temperature-resistant conveyor belts or specialized materials such as 316L stainless steel to ensure long-term, stable operation. Furthermore, to meet specific customer needs, manufacturers can also integrate various auxiliary functions into the equipment, such as explosion-proof motors, material level detectors, and blockage alarms, further enhancing automation and safety. Finally, customization capabilities also include system integration. Excellent manufacturers not only provide a single elevator, but consider it as part of an entire material conveying system, offering seamless integration with equipment such as crushers, screens, and packaging machines. This comprehensive, customized service ensures the coordinated operation of the entire production line, effectively improving overall production efficiency.

Belt Type Bucket Elevator plays the role of material height difference transfer in industrial production. Its closed structural design helps to control the scattering of materials during the lifting process. The equipment consists of traction belts, hoppers, drive devices, and head and tail parts. In the processing of different materials, it is necessary to select the appropriate hopper form according to the physical properties of the materials. The operating performance of the equipment is affected by many factors, including but not limited to the equipment maintenance status, material loading method and operating speed. In scenarios where vertical material transfer is required, Belt Type Bucket Elevator is a common choice.